After all the enthusiasm for basic pin-gauges, I thought I might have missed something.

Being unable to pass up gorgeous box-wood screwed gauges priced at 50p when they come up at car boots

(which they do, often) I have "some" in a Tesco 6-bottle wine box.

Pieces of scrap timber to hand. I worked my way through, and herewith my observations:

Two of them had stems that stuck.

Most of them had stems that were loose in the non-screw direction.

Two had stems that slid with no sideways motion at all.

I found no evidence of Clenton-style "camming" in any of them

More interesting was their performance in use. In the more recent examples, with a long, narrow, sharp pin, much

more care was needed (including the "running on the edge of the stem" technique") to prevent the pin digging in,

following the grain, or juddering. The gauges were still usable, just more work to use.

The easiest gauges were those with a well worn, short pin - just a nub, really. These were easy to use,

and left a clearer mark.

In hindsight, this is fairly obvious; a fine, long pin is likely to penetrate deeply, which serves no practical purpose;

the visibility of a mark is mainly determined by its

width not its depth.

So we may have found that most unusual of tools, one which which works better when blunt. Should

save some arguments.

I found the fact that the working point is hidden by the stem slightly disconcerting, since I'm used to being able

to see the point. However, I acknowledge that (in practice) the gauges are perfectly usable,

just not quite as easy to use (since the pin comes out the back of the stem, its position is "obvious" if

not actually visible). I'd probably get used to it, I suppose.

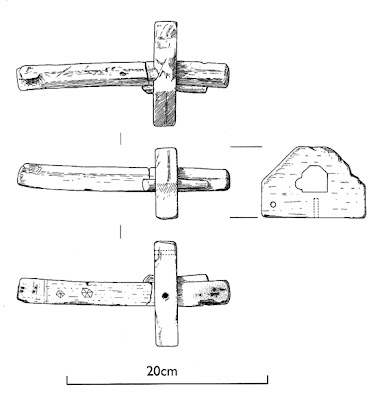

In short - as carpenters since the Mary Rose have known - the classic marking gauge works OK. What a surprise.

Here's a marking gauge from the Mary Rose (the museum was dark, so the picture is not great)

However, this does not mean it cannot be improved on.

The across the diagonal screw feature of the 5061

make the stem slide

perfectly, without wobble, and is even tolerant of seasonal movement and inaccurate manufacture.

However, since it requires a little adapter piece, its invention probably had to wait on injection moulded

plastic (which is how Stanley make the little piece).

I also prefer the diagonal fixing of the pin; this not only makes it visible, but it builds

a high degree of "trail" into the design, making it far less prone to catching and juddering.

It is of note that the 5061 was not sold as a "premium" gauge, it was just Stanley's normal

offering, at a normal price. I have NO IDEA why they stopped making it.

BugBear