PaulO

Established Member

What techniques do people prefer for cutting to a tenon shoulder line?

1) Approximate cutting with a bandsaw / tenon saw first followed by

a) Paring to a scribed line with a chisel? If so, do you aim for a convex shoulder (convex towards the tenon)?

b) Trimming to the scribed line with a shoulder plane? If so, how do you avoid break out?

2) Go straight for the scribed line with a bandsaw / tenon saw / table saw?

3) Mark the line with a 3B pencil then aim with an axe?

Any other suggestions?

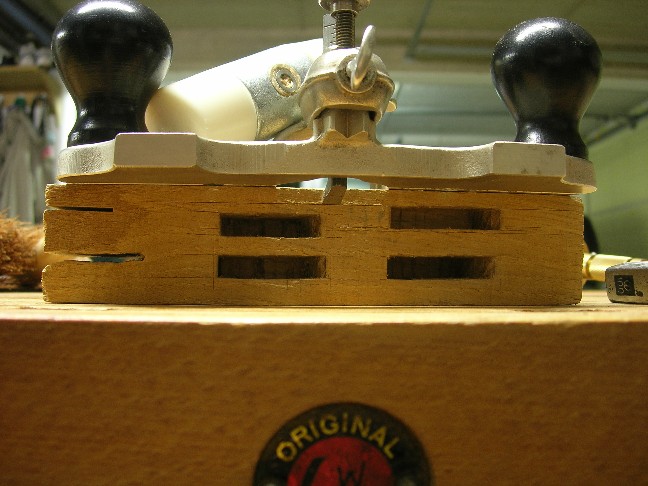

I think I would go with 1a, but I am thinking of investing in a large LN shoulder plane. I am guessing it should be ideal for trimming shoulders?

1) Approximate cutting with a bandsaw / tenon saw first followed by

a) Paring to a scribed line with a chisel? If so, do you aim for a convex shoulder (convex towards the tenon)?

b) Trimming to the scribed line with a shoulder plane? If so, how do you avoid break out?

2) Go straight for the scribed line with a bandsaw / tenon saw / table saw?

3) Mark the line with a 3B pencil then aim with an axe?

Any other suggestions?

I think I would go with 1a, but I am thinking of investing in a large LN shoulder plane. I am guessing it should be ideal for trimming shoulders?