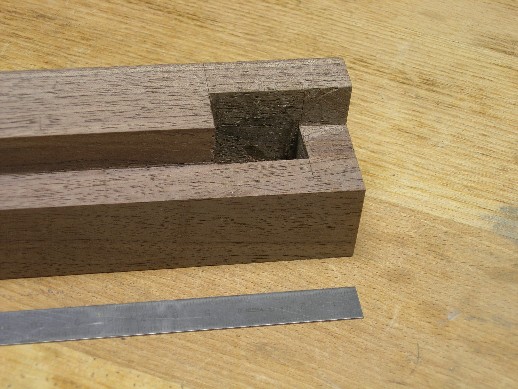

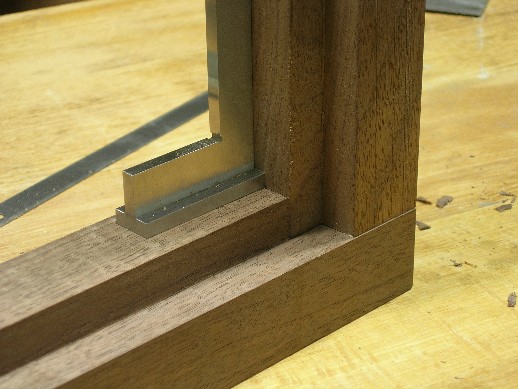

Andy, I am sure MArc will contribute an answer to your question, but I can give you one use. Last year I made a screen door for my modest domicile, and I did the mortises and tenons, including the cross piece in the centre of the door, and not thinking it through clearly enough I ended up having to cut stopped rabbets in the inside of the door to accept the screens.

It involved doing blind rabbets and not a little bit of blue air. I thought about it for some time afterwards, mostly when I was sitting on the back deck looking at it through a glass of local vin du pays, and worked out, (in my head that is) pretty much what Marc illustrated. Doing it that way I could have done through rabbets and then joined them together with little fuss, it would be much easier than what I did, and doubtless would have looked better.

Thanks Marc for posting that as it validates what I figured out and since you did it first I can see it better in my head now to.

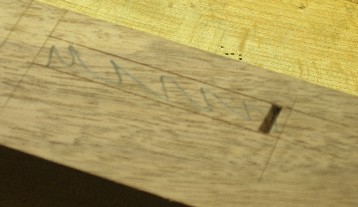

As to the original question I do it all by hand, because that is what I want to do. I recently built a closet organizer that involved forty two mortise and tenon joints, 2.5 inches long X 2 inches deep X .5 inches wide. The first mortise took me near half an hour, the last six less than an hour.

James