Hi Allen

Blister":28pt3ftf said:

So you have my instruction book :mrgreen: , is it any better than A4 bit of paper in a ring binder sleeve ?

Don't know about the ring binder but a lot more than an A4 sheet, that's why it's taking me so long

Blister":28pt3ftf said:

The knock out bar I think is quite pony , little or no thought go into it , but again its not the end of the world , I will make one more suited to the quality of the lathe , no big deal

Be carefully you don't overdo it with the knock out bar. You may damage the end of the MT.

Blister":28pt3ftf said:

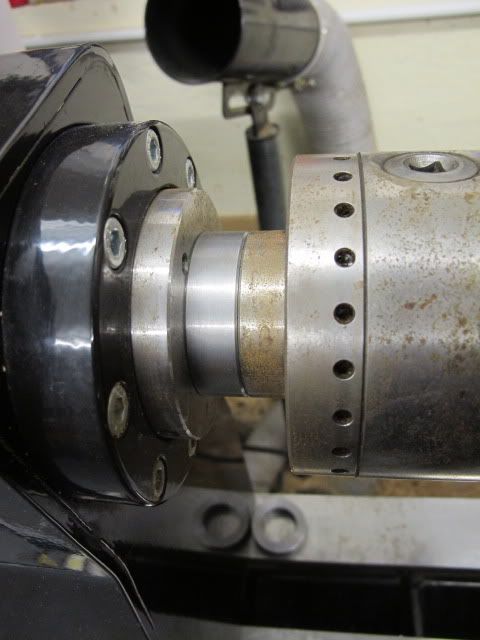

The headstock spindle length is an issue :? and none of Axminsters back plates fit as I phoned them today , They advised going to a local machine shop and getting a spacer made , O bum , I have a One Way stronghold chuck as well but as yet Have not tried to use it on the lathe but will in the morning

anyone want to buy a chuck .

I've had the same issue on other lathes with the various back plates I have for my Super Precision where they don't register fully.

If you are serious about selling yours let me know, I could always do with another

Blister":28pt3ftf said:

Speed display , To be honest I never look at it anyway , always have the speed set for me when I can see all is well :mrgreen: , big out of balance items are set slow ( yes I am a coward ) the more in balance the faster the speed :lol:

Not a coward, that's the way to do it =D>

Blister":28pt3ftf said:

As stated I love the lathe , but its like buying a RR with some cheap bits that just slightly take the edge of it , Quality should be quality 100 %

Yes I can understand that and do agree