condeesteso

Established Member

On the case Jim. Soon as I know, you will too. I would like to get it over here, mainly because it has been a few years since we last swung a pair of French balls around the British Isles... n'est ce pas?

No skills":omvdgtsu said:Thats a neat little thing. Bet Fred Dibnah had a full sized one

bugbear":3ib4m5mi said:marcros":3ib4m5mi said:bugbear":3ib4m5mi said:It's a good job we're not discussing a flywheel controlled auto-feed drill; those things are hard to understand when they're right in front of you.

BugBear (owner)

no picture... it doesnt exist!

I'll see what I can do - but be warned, the picture won't help. You will misinterpret what you see. :-"

BugBear

marcros":2wolt6ze said:Thanks BugBear. Is it regularly used?

condeesteso":2ypawtlg said:BB - if I am ever to understand that, I will first need to know where the 'quill' is, please... then I may stand a chance. i suppose a video is pushing my luck?

bugbear":1x21m4tb said:It's the uppy downy, roundy roundy...

I went and picked up this little boy this morning. Oh boy does my back hurt now...gounthar":1y5lyc6p said:Very interesting read!

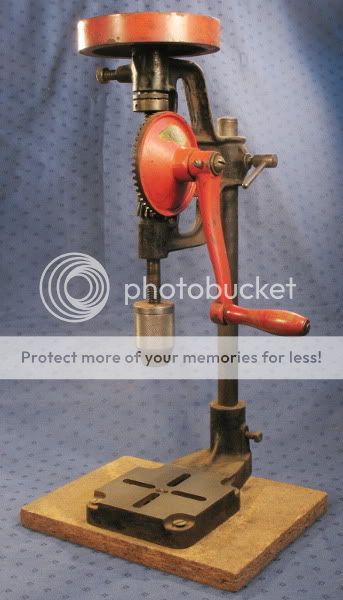

I am interested in this one, and hope to get it next week:

.

I hope I will be able to start mortices, cut toy wheels and so on. :roll: