You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

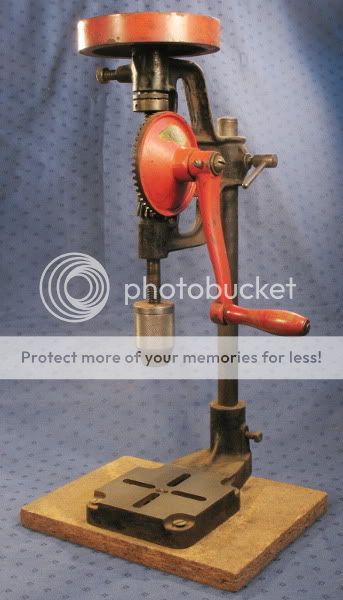

Hand Operated Pillar Drills

- Thread starter marcros

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

marcros":kfnuvsxd said:interesting read, Scouse. I fancy having a go at a restoration of one of these, if I can locate a local one, ideally with 2 speeds.

Are the chucks similar to a modern drill?

it just so happens my grandad handed me one down that he used to use in the motor trade in the 1950's. it's sat in my loft gathering dust and I work in leeds, hmmmm rubs chin

Lee J":2hou06oq said:marcros":2hou06oq said:interesting read, Scouse. I fancy having a go at a restoration of one of these, if I can locate a local one, ideally with 2 speeds.

Are the chucks similar to a modern drill?

it just so happens my grandad handed me one down that he used to use in the motor trade in the 1950's. it's sat in my loft gathering dust and I work in leeds, hmmmm rubs chin

Lee,

I would be interested to see it. The only problem is if there isnt any pics, then it doesnt exist!

Where in Leeds are you?

Hi,

http://www.leboncoin.fr/collection/322439536.htm?ca=17_s

Here is another one, less attractive, but with balls too:condeesteso":3o9y8ocf said:here's another pic, kept it in a secret place...

http://www.leboncoin.fr/collection/322439536.htm?ca=17_s

S_L_Nielsen

New member

Let me drag this old thread out.

I first saw a pillar drill with the ball feed system here in Denmark, some 20 years ago.

I have been investigating it a bit on Practical Machinist.

Nice to see that there is more than two in the world with this system.

Best regards

Søren

I first saw a pillar drill with the ball feed system here in Denmark, some 20 years ago.

I have been investigating it a bit on Practical Machinist.

Nice to see that there is more than two in the world with this system.

Best regards

Søren

S_L_Nielsen

New member

Let me see if I can attach the pictures.

No such luck until fourth post..

No such luck until fourth post..

£14.99 (£3.00 / count)

VEVOX® FFP2 Dust Mask - Set of 5 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

S_L_Nielsen

New member

Third post. Sorry..

S_L_Nielsen

New member

Pictures here :

Thread from Practical Machinist here :

http://www.practicalmachinist.com/vb/an ... ss-255119/

Best regards

Søren

Thread from Practical Machinist here :

http://www.practicalmachinist.com/vb/an ... ss-255119/

Best regards

Søren

jaywhoopee

Established Member

bugbear":2ltkbt2g said:Here we go:

Looks like a drill with a flywheel on the quill, right?

But where's the feed?

Here we go...

The quill is threaded, and passes through the (also threaded) flywheel. Consider two extreme cases.

#1 If the flywheel stays still, and the quill rotates, the quill descends.

#2 If the flywheel rotates at the same speed as the quill rotates, the quill does not descend.

Here come the interesting bit; the quill also "supports" the flywheel a bit. If there's back pressure from the quill, the quill/flywheel contact (and friction) is increased, so the flywheel rotates more, leading to more of case #2

If the back pressure decreases, the flywheel rotates less, leading to more of case #1

In other words, the rate of descent varies inversely with back pressure. Neat.

The adjustment screw, visible below the flywheel, adjusts the friction between the quill and wheel.

In short, this thing is VASTLY more complex than it looks.

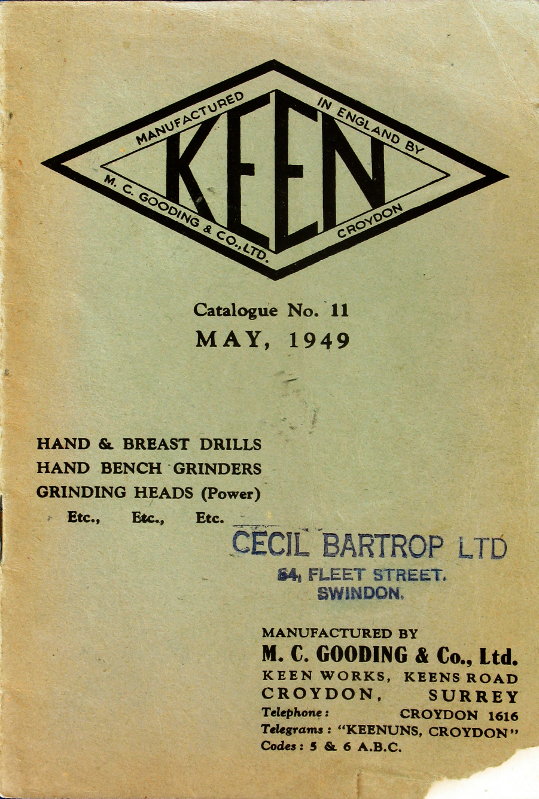

Edit; google gives:

http://www.gracesguide.co.uk/M._C._Gooding_and_Co

as the maker.

BugBear

I just picked one of these up at a car boot sale and I think it's the same as the one in your photo, so I'm incredibly glad to have found your explanation of how it works!

I couldn't find any markings other than a "British Made" sticker on the crank, but am I to take it that it's made by M C Gooding?

The main problem with mine is that the springs inside the chuck are all missing, so I'll need to figure out what to replace them with ...

It was only £4 and such a nicely made bit of kit I had to have it. Now I understand a bit more about how it works I'm even happier I bought it

John

Chucks are fairly simple things. You should be able to find something to unscrew to dismantle it. If it's a 3-jaw, a common pattern has three wedge shaped jaws, each with a blind hole on either side. Three compression springs loosely fitted into the holes push each jaw away from its neighbours onto the inside of the cone. The springs are about the size of those in a ball-point pen, which is one obvious place to look for replacements.

jaywhoopee

Established Member

AndyT":mcmsx6he said:Chucks are fairly simple things. You should be able to find something to unscrew to dismantle it. If it's a 3-jaw, a common pattern has three wedge shaped jaws, each with a blind hole on either side. Three compression springs loosely fitted into the holes push each jaw away from its neighbours onto the inside of the cone. The springs are about the size of those in a ball-point pen, which is one obvious place to look for replacements.

Thanks for the tip Andy,

I already managed to get into it, which is how I know the springs are missing.

I'll have a rummage around the house and try and find some suitable donor pens

John

lica_mobilu

New member

Hello bugbear,

Can you please upload a photo of the yellow label on the crank wheel? I have just bought a pillar drill just like yours but the label is 95% gone.

Thank you,

Bogdan

Can you please upload a photo of the yellow label on the crank wheel? I have just bought a pillar drill just like yours but the label is 95% gone.

Thank you,

Bogdan

bugbear

Established Member

lica_mobilu":3rl53ftr said:Hello bugbear,

Can you please upload a photo of the yellow label on the crank wheel? I have just bought a pillar drill just like yours but the label is 95% gone.

Thank you,

Bogdan

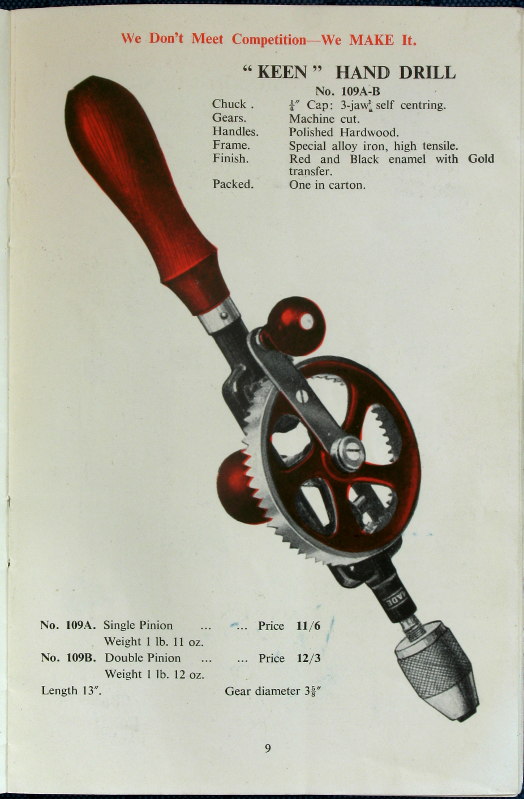

This is probably more informative (from a catalogue)

BugBear

Similar threads

- Replies

- 5

- Views

- 798

- Replies

- 46

- Views

- 7K

- Replies

- 8

- Views

- 4K