jimi43

Established Member

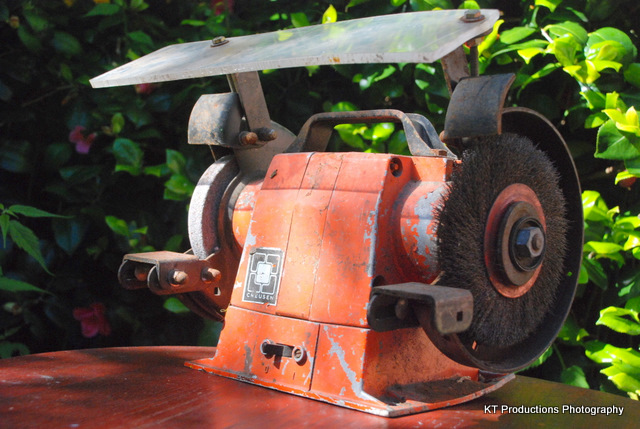

Over on the Bootfair thread in the General Chat section...I mentioned a bit of a find at at the fair last weekend for a tenner:

and I said it was off to the workshop to be refurbished .

Firstly the entire machine needed to be dismantled and then all the rusty bits were left overnight in a vat of CORRO DIP....

Once that was done a quick scrub with a copper brush to remove the slag and then primed and painted.

I used Halfords satin black for the black bits which is a wonderful and accurate finish and Rover Carnival Red for the body...

The cable was damaged so that was replaced with heavy duty flex and I thought I would push the boat out and pop over to Axminster for some new wheels.

I wanted transfer the old wire brush to my crap grinder and the old stone was completely shot. Luckily I managed to find a red stone in the sale at only £8 so I splashed out for a white 40mm one for plane irons...

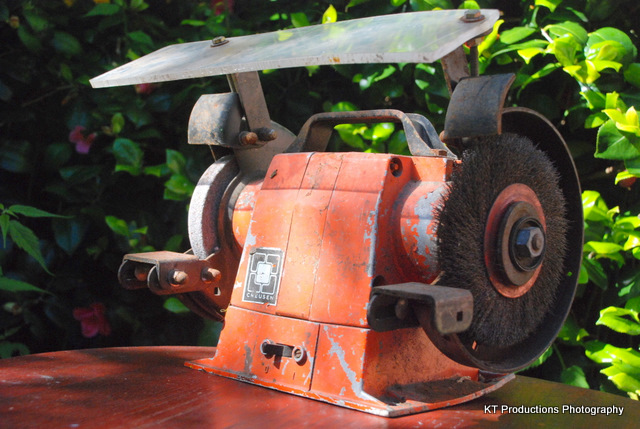

The finished article:

So slightly more than a tenner in the end but one hell of a machine.

I switched it on to test....very smooth! A huge difference to my old machine...but on switching off I thought the switch was broken as it just kept going...and going and going.....it took AGES to stop....incredible!

So...off to make a nice little clamp/rest for both sides and cut a new full sheild....for info on that...see the "Cutting Perspex" thread!

Later guys and gals! :wink:

Jim

and I said it was off to the workshop to be refurbished .

Firstly the entire machine needed to be dismantled and then all the rusty bits were left overnight in a vat of CORRO DIP....

Once that was done a quick scrub with a copper brush to remove the slag and then primed and painted.

I used Halfords satin black for the black bits which is a wonderful and accurate finish and Rover Carnival Red for the body...

The cable was damaged so that was replaced with heavy duty flex and I thought I would push the boat out and pop over to Axminster for some new wheels.

I wanted transfer the old wire brush to my crap grinder and the old stone was completely shot. Luckily I managed to find a red stone in the sale at only £8 so I splashed out for a white 40mm one for plane irons...

The finished article:

So slightly more than a tenner in the end but one hell of a machine.

I switched it on to test....very smooth! A huge difference to my old machine...but on switching off I thought the switch was broken as it just kept going...and going and going.....it took AGES to stop....incredible!

So...off to make a nice little clamp/rest for both sides and cut a new full sheild....for info on that...see the "Cutting Perspex" thread!

Later guys and gals! :wink:

Jim