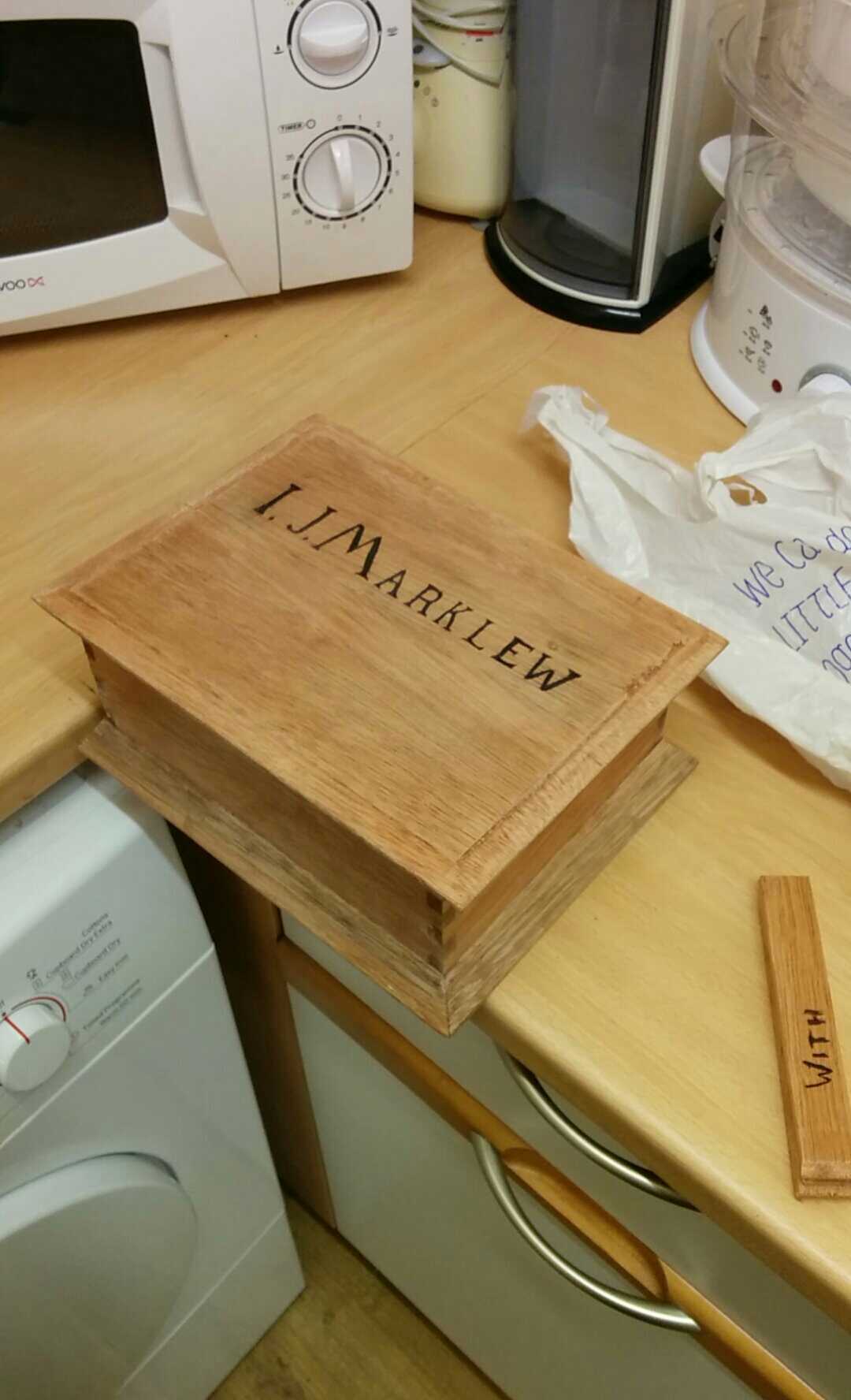

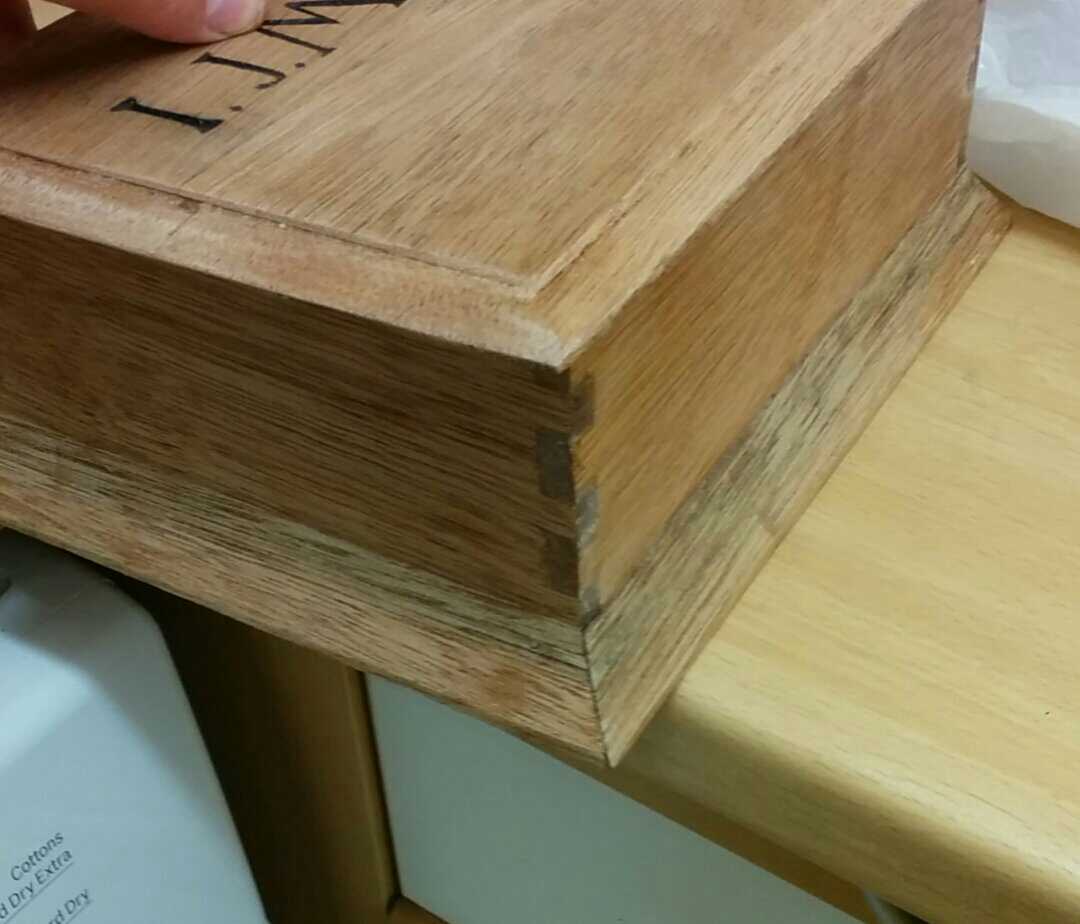

Spent 5 hours carefully routing out a square aperture, squaring the corners very carefully with a Japanese saw, then making a panel to fit inside it very snugly.

Only trouble is I've made the panel such a good fit (read tight as @@@@) that I need to fit a couple of knobs to it so it can be removed without having to push it from behind. Oh well better than a sloppy fit ha ha

Still a successful day in the end

Only trouble is I've made the panel such a good fit (read tight as @@@@) that I need to fit a couple of knobs to it so it can be removed without having to push it from behind. Oh well better than a sloppy fit ha ha

Still a successful day in the end