enecosse

Established Member

Found this forum a couple of months ago, been browsing thougft I would post some projects, This is purley a hobby, had never done any woodwork befor the first project on here, I am a plater /welder type.

Decided to clad my stair in oak,not long before first leason in woodwork

bought the oak 250 wide for the treads, 2 weeks in the house it curled, had to cut it up the middle and reverse grain, also used walnut miller dowels to fix down, stringers were hard to survey/mark out, easy to get wrong, worked out alwright though. made the handrail brackets from stainless and had the machine shop turn the ends from stainless also.

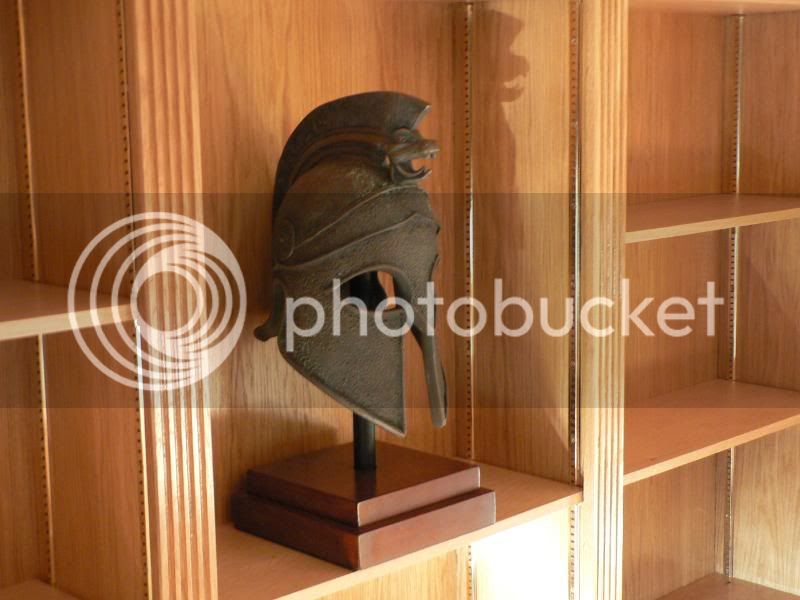

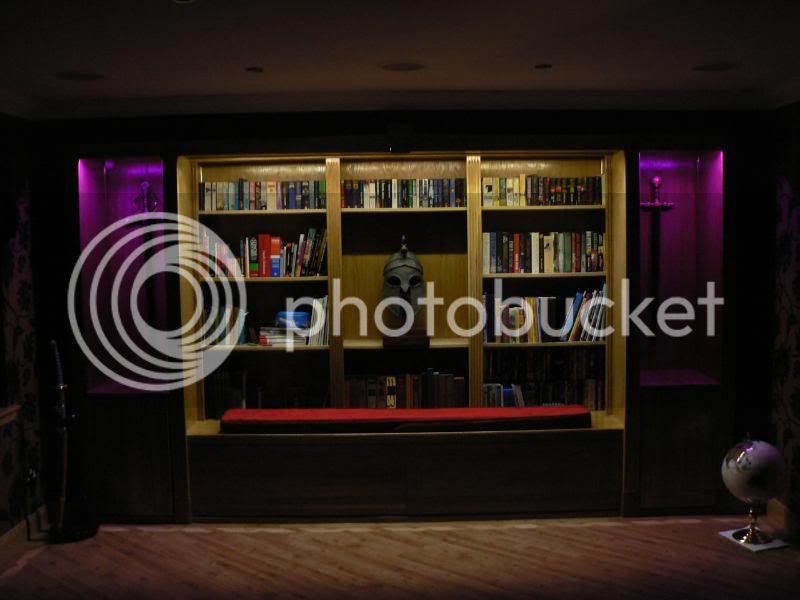

2nd project jumped in a bit deep bought net of vat 3k worth of rough cut

walnut and made a bed headboard, side tables, window cil, doorfacings

wardrobe sliding doors, room divider sliding doors, cabinet, the list goes on,

sink unit

bed

headboard

wardrobes

going to do a jump too amny pics

Decided to clad my stair in oak,not long before first leason in woodwork

bought the oak 250 wide for the treads, 2 weeks in the house it curled, had to cut it up the middle and reverse grain, also used walnut miller dowels to fix down, stringers were hard to survey/mark out, easy to get wrong, worked out alwright though. made the handrail brackets from stainless and had the machine shop turn the ends from stainless also.

2nd project jumped in a bit deep bought net of vat 3k worth of rough cut

walnut and made a bed headboard, side tables, window cil, doorfacings

wardrobe sliding doors, room divider sliding doors, cabinet, the list goes on,

sink unit

bed

headboard

wardrobes

going to do a jump too amny pics