So, late update, more work has taken place.

Not saying great work, just more work (hammer)

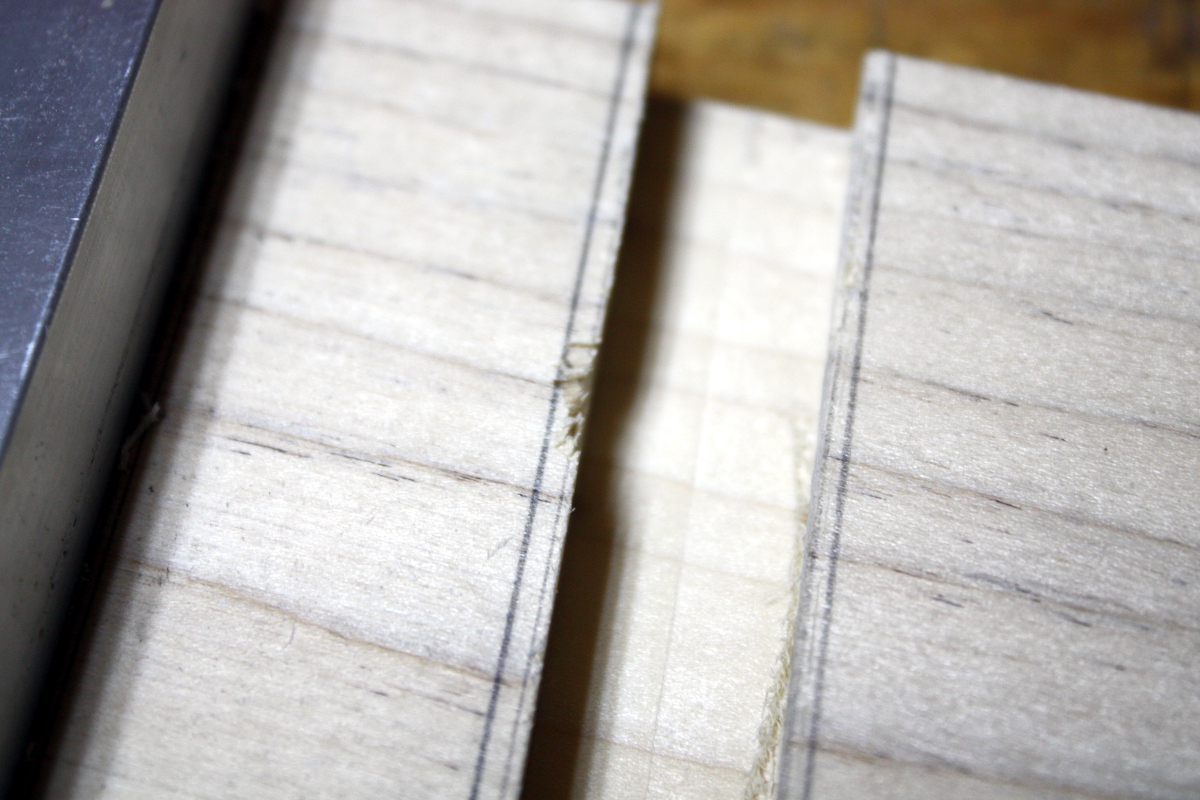

Anyway... decided against doing another sliding dovetail for the middle shelf and opted just to cheat and do housing joints, cut the normal way by hand with chisel.

Nothing hugely noteworthy with these, though I will say it's nice to work poplar if you have sharp tools.

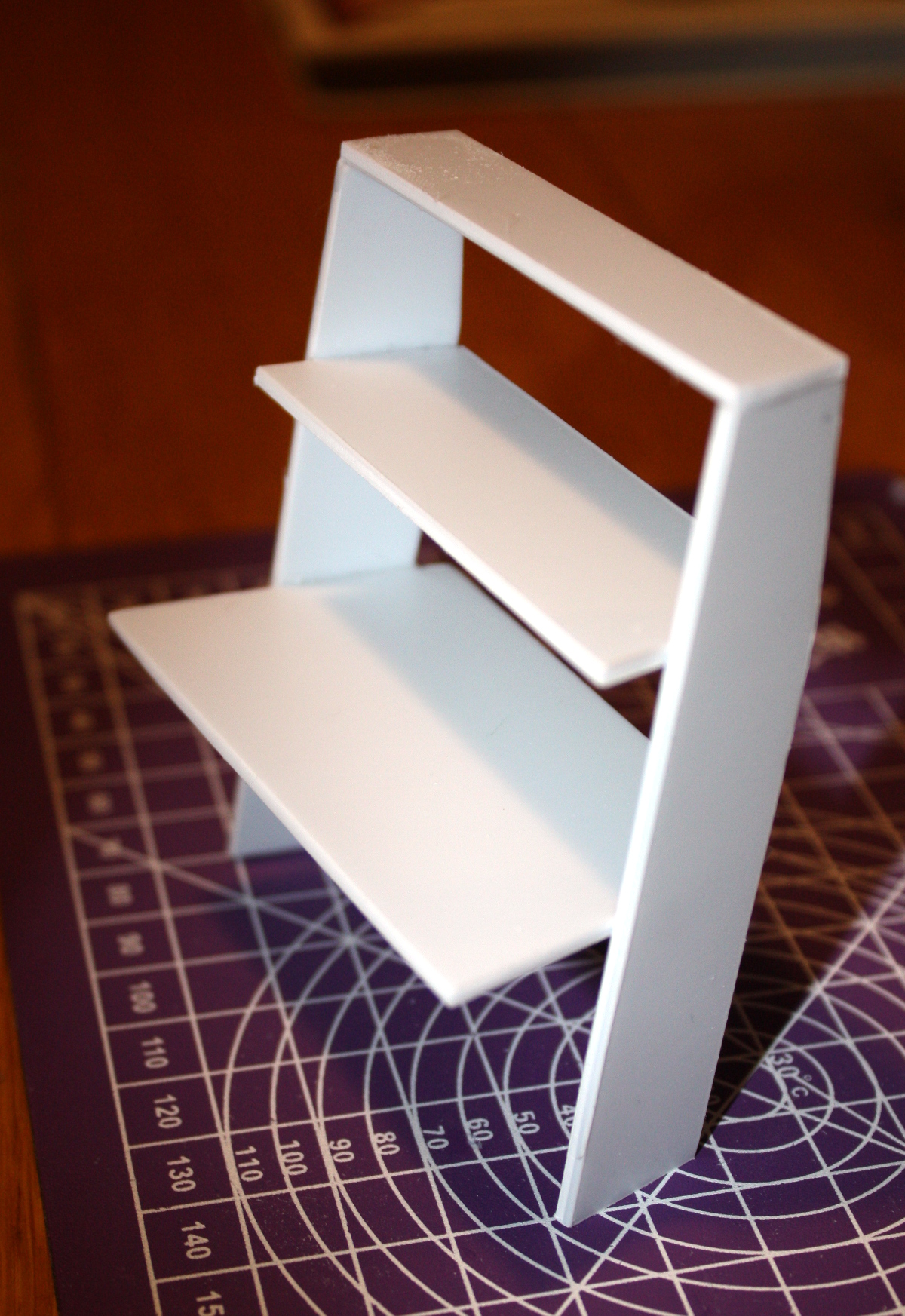

With the housing joints cut, I tried a test fit.

Rather awkward to put together - and there's that clamping problem that even I could see coming before starting all of this. That clamp's one of the largest I have, they were comfortably large enough to make the workbench with padding on the clamps and still they only barely make it here.

That’s going to dent the outside corners of the edges, but that’s okay, they’ll be shaped to a round profile and those corners are coming off anyway. I will need to take the angle grinder and flapdisk to the clamps though, they’ve been “stored” outdoors for some time and the rust is criminal (don’t judge me, there was noplace else to put them and the job of rehabbing them has been on the list for a while now).

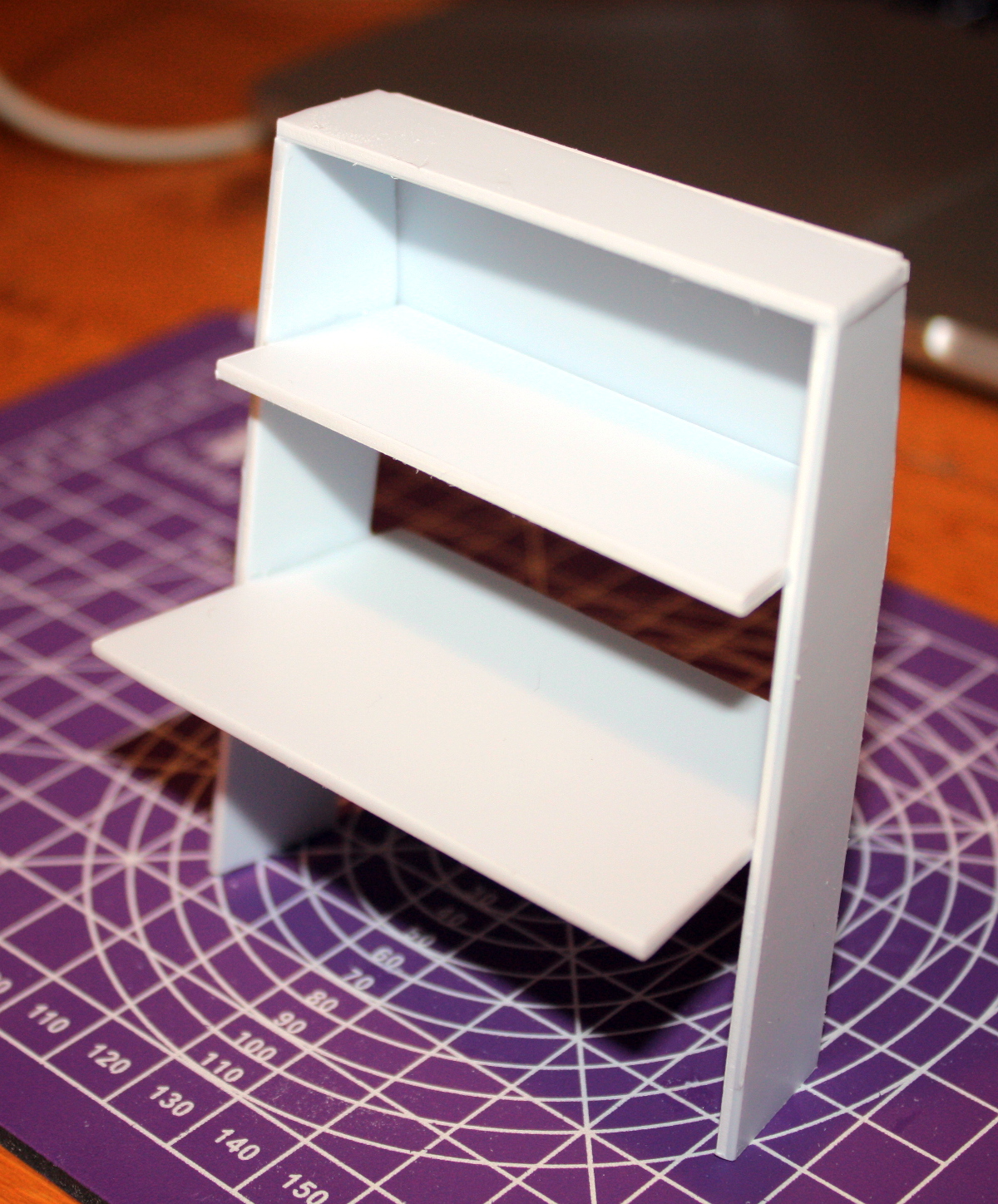

More annoyingly, the housing joints didn’t seem to fit very well…

And as a result, the sides are pushed out of true.

So some fettling was required. Did that, or thought I had, and then without the middle shelf, while I had the whole thing together, I scribed the top shelf with a pencil.

(That's from earlier but it looked the same).

After thinking about it a bit, I double-checked the angles of the sides of the walnut board – because it’s the core around which all this is built – and then I used the angles of the walnut board, and the width from the scribe marks (and yes, I double-checked that the sides were plumb to the desk before scribing), and used those two to cut the top shelf.

I didn’t cut them according to the scribe marks’ angles because there’s a little bit of twist in one of the sides - not much, maybe 4-5mm over the full length of the side - but it's poplar, not oak, so the top shelf should be able to pull that back to the walnut board’s angle.

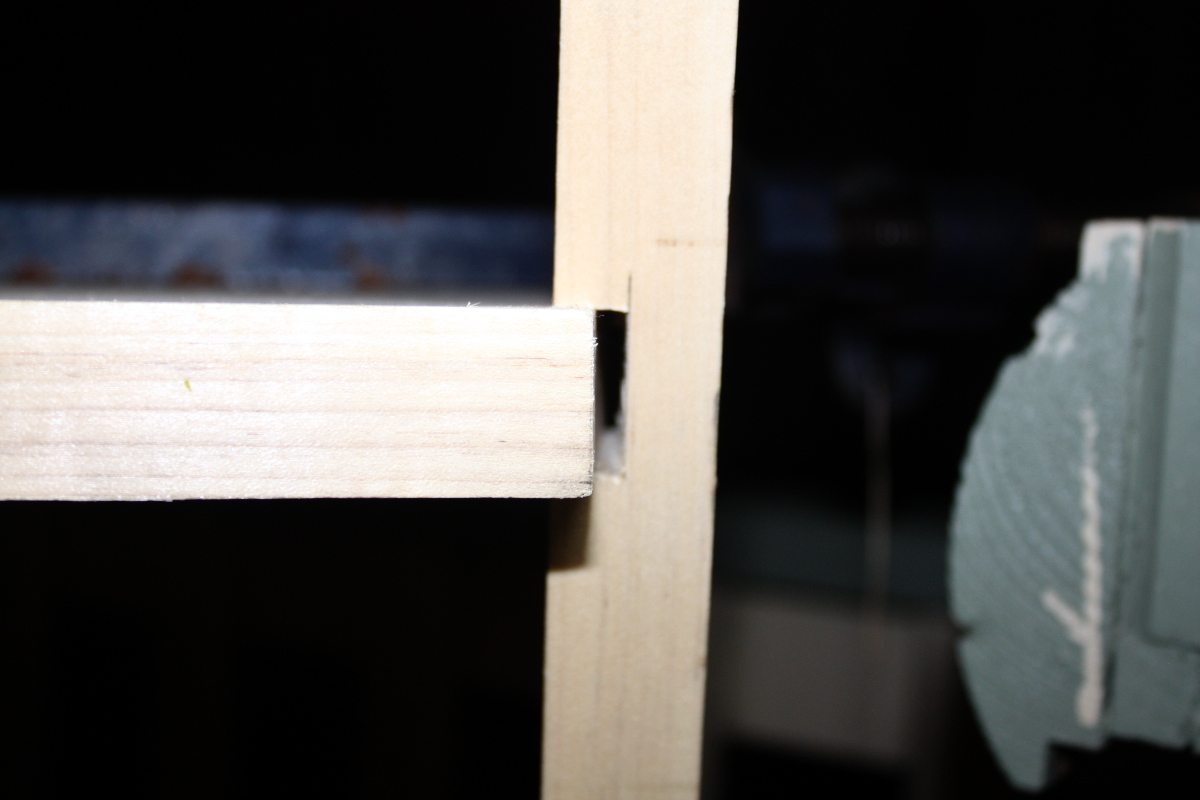

And of course, because it’s an angled cut on the end of the board, the dovetails get interesting. Since I don't want to spend a few hundred quid on a Bridge City bevel, I did the sane trick to get the angles (1:6 on one side and 1:8 on the other). And did the two-dividers approach for the spacing.

Probably the most finicky dovetail marking I've ever done. And no guides for sawing this time, it's "can you actually saw to a straight line" time, or as I call it, "no" time.

Still though, dousing a joint in glue hides a multitude of errors...

Also, holding a 30" board in mid-air five feet up while you try to scribe from tailboard to pinboard is a great way to teach the neighbour's kid new swear words. Just sayin'. But eventually, got the job done to within a certain value of "acceptable" and assembled it, or tried to. With the middle shelf in place, there was a solid inch of air between the end of the top shelf and the dovetail joint on the right side. I mean, there are gaps you can fill with sawdust and then there are gaps you can't...

Turns out, that middle shelf wasn't as fettled as I thought it was. Back to the #04 and off with a mm on either side of the shelf and more test fitting but eventually, I got it to all go together, albiet with pursuasion from the clamps. And with that stage reached, brought it inside...

That middle shelf is definitely not done yet; it’s still a few mm too wide at the back, while being about right at the front but the end result is that there’s a lot of stress on the right hand dovetail joint.

There’s a whole 2.4mm of a gap there at the bottom, purely because the shelf is spreading the sides (I assembled without the middle shelf to check – it went together perfect square and true). I have some more fettling to do there tomorrow. But that wasn’t the point of this assembly (or bringing it indoors for that matter), it was more to check sizes. That desk seems so low off the ground that there’s no way it’s right, right?

Nah, it’s grand, the client is happy.

It’s now all back in the shed with the middle shelf removed. Tomorrow I’ll work on fettling that middle shelf fit and when that’s good enough, I’ll take the desk all apart and begin work on inlays, decoration and shaping. The inlay won’t be entirely conservative – the client isn’t a huge fan of traditional marquetry because he can’t spell “traditional marquetry” yet - but an inlaid race track for cars would be cool, and an blue resin ocean on which to recreate the death of several hundred people in the freezing waters of the north atlantic would be a very desirable feature apparently. I don’t know, don’t ask.

I also want to cut a 7mmx13mm channel in the underside of the middle shelf – that’ll house an LED strip in an recessed aluminium channel with diffuser (ebay’s a great tool these days). That does mean I need to figure out a way to run a mains cable from that shelf to the ground, in a way that doesn’t lead to a seven-year-old finding a way to pull it out of the desk and strangle the cat with it.

Anyone know of a neat way to chase a cable through a piece of wooden furniture over a distance of around five feet in total? Cable clips are not okay, and just routing out a channel and epoxying the cable in seems somewhat unmaintainable in the long run if you ever had to replace the cable…

Speaking of routing, for some of the resin and the LED channel, I thought I might go back to the beast and try it again, but this time with a better way to hang on to it.

So, y'know, if the next time you hear from me on here it looks like I have an accent, it's because I routed off two of my fingers...