So on my last update, I said this should all be wrapped up by xmas...

...and shockingly, I was right

Okay, granted, I did pause it for a while to do

this and

this, and there was the whole chase-the-promotion game in the middle (now a

senior engineer thankyouverymuch so even my job title thinks I'm getting too old for this nonsense...) but still.

A year and four months to the sodding day. Not exactly covering myself in glory on the speed front here.

Anyway, last time I had just finished roughing out the curves on the walnut desk, and I didn't know it at the time but I was going to spend the bulk of the rest of the time on that part. I wanted to put some decorative inlay in there to (a) drag the eye away from the gappy joints to spot all the defects in the wonky inlay instead, and (b) put a racetrack in the desk to meet the initial spec.

That box is from Custard, and contained some beautiful thick veneers that he just sent as well as a few pieces of seriously pretty wood (first time I'd even seen cherry, or rippled sycamore and now I need to have more of it so I've had to locate a new, more expensive timber yard to plunder). Thanks again Custard, that was utterly uncalled for and totally appreciated!

So I dug out my inlay tools...

and my new bending iron...

and after laying out the design in pencil with compass and a new cheap marking gauge from china, I started to cut the inlay grooves.

I did have some fun with thicknessing, and had to make another tool for doing that. Well, I say tool, but I think I'm abusing that word somewhat...

Yes, it's a bit cut from an old induction-hardened-teeth saw plate that wasn't usable as a saw anymore clamped to a piece of scrap with a hole drilled in it. Look at me,

toolmaker extraordinaire. But well, it kindof worked. And I could trim the edges afterwards by doing the cooper's plane thing only with a block plane.

So once you have the material ready, the rest is pretty simple. Cut the grooves (those straight lines in the middle of the board were the hardest, I had to use that veritas freehand inlay cutter (

this one and a straight edge).

Make sure the groove is clean, then take a metal hammer and tap on one side of the stringing material against a metal anvil (which is what that small red vice was for) to compress the wood fibres a bit; then you lay a bead of glue into the groove with a syringe and push the stringing material down into it as cleanly as you can and clean up the mess made because you went too heavy on the glue and it squeezed out everywhere. Then realise you've snapped the stringing in the middle by pushing down too hard and that the fracture runs below the surface of the table, swear a lot, dig it back out with a pointy but not wide awl, clean out all the glue from the groove while trying not to widen it too much, prep another bit of material and do it over.

You may need to learn new swear words for this last part if you did it as often as I did, just for the sake of variety.

For the curvy bits, plug in the bending iron and wait until the entire shed stinks of a fire because you didn't clean out the dust before you plugged it in, and when the panic has subsided after you realise why it smells like a fire, gently rub the stringing material up against the hot surface until it warms and bends easily. Try not to pull so hard it breaks and you accidentally sear your fingers on the now rocket-hot bending iron because you used up most of your swearing for when you broke the stringing material on the easier straight bits. Also try not to bend through too tight a radius and then realise that you have to straighten it a bit to get it in the groove because by now you're getting annoyed at things. Once you have it

just a bit tighter of a radius than the curve, tap it, syringe the glue into the groove and shove it in carefully.

Oh, and because this isn't fiddly enough, make sure all the joints are scarf joints and not butt joints, because Reasons.

When the glue's had a little time to set - and you don't have to wait for a full cure really - trim down to almost the surface with a chisel. Carefully, or you'll yank the wood out of the groove and you're back to swearing again. You'll take the remains all the way down later with a #080 cabinet scraper and a card scraper.

Now, that's a racetrack, but all racetracks have something else - a start/finish line. I know this from my extensive experience watching formula one on the telly long enough to go

"ah hell, they don't jump over rivers with funny horns in this one?" before switching off. Well, there's no way in hell I can inlay a checkerboard with inlay material, so I resolved to knuckle down and cheat like I was in Eton.

It turns out that the UK does not have a shortage of cardboard boxes. It also makes this stuff:

I mean, it cost as much to ship ten as it did to ship one (I think I don't even make the cut for the "noise" level in their order books) so I bought a few kinds, and right there in the middle is what will do for a checkerboard pattern.

Now I just cut out a shallow recess using knife and chisel and tidy it up with the #722...

...and then discover that it's just a hair too wide and put in another bit of stringing to keep everything tight and also to make the actual start/finish line. That was definitely planned. That's my story and I'm sticking to it.

And that was the last of the inlay. I had lots of plans for inlaying all manner of things - times tables, alphabets, the lot - only I realised that by the time I was done, he'd be in college, so I cut my losses.

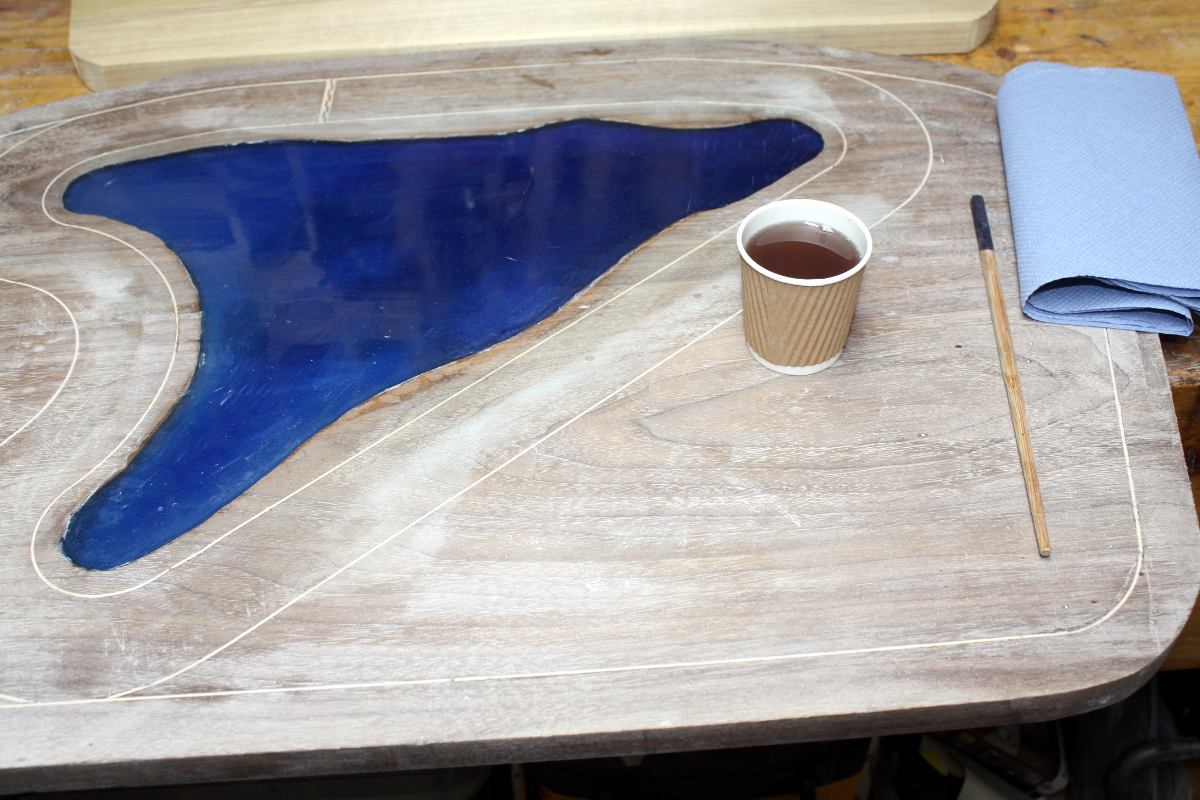

Next up, the sea.

And I didn't have any way around this that I could sea (boom, boom! here all week, tip your waitress...) but to do this with a router. I didn't think the chisel could cope without wrecking the stringing or even shocking the glue joint and parting the panel down the middle, and I didn't know of any other tool I could use (maybe a fostner bit if I had a drill press, but I don't). So. The old enemy returned. And it wasn't going to be stable over this large an excavation so it needed a new footplate.

That done, I had to strap myself into more PPE than I care to wear normally, and then it was a case of shallow cuts inside the lines and carefully walking up to a point about 1cm inside the stringing and excavating down about 1cm as well (the board's 22mm thick here so I figured that was stable enough). This took two days because have I mentioned that that screaming spinning finger eater terrifies the living **** out of me? BECAUSE IT DOES. I don't know how you guys use it as an everyday tool, if I had to do that I'd quit and go write software for a living.

Anyway...

With this done, the next thing I wanted to do was to seal the grain. I didn't want the resin wicking through the pores and looking weird, which had happened on a few test pieces. So...

Mix with turps, apply with a glue spreader, leave to dry overnight.

This, by the way, was a mistake - or rather, applying it only inside the sea was a mistake, I should have applied it everywhere but I was afraid of ruining the stringing. I still don't know how I'd have done this better, but more on that in a bit.

Next morning, I glued down reflective film in the sea (that stuff you get for windows so they reflect heat in summer).

There's to be a light above the resin; this reflects that light back up through the resin so the colour isn't jet black. And because I was afraid the resin would stick to the foil and the foil wouldn't stick to the wood and the whole thing would pop up in the middle or out entirely, I drilled a lot of 2mm holes through the foil for the resin to leech through and anchor against the walnut.

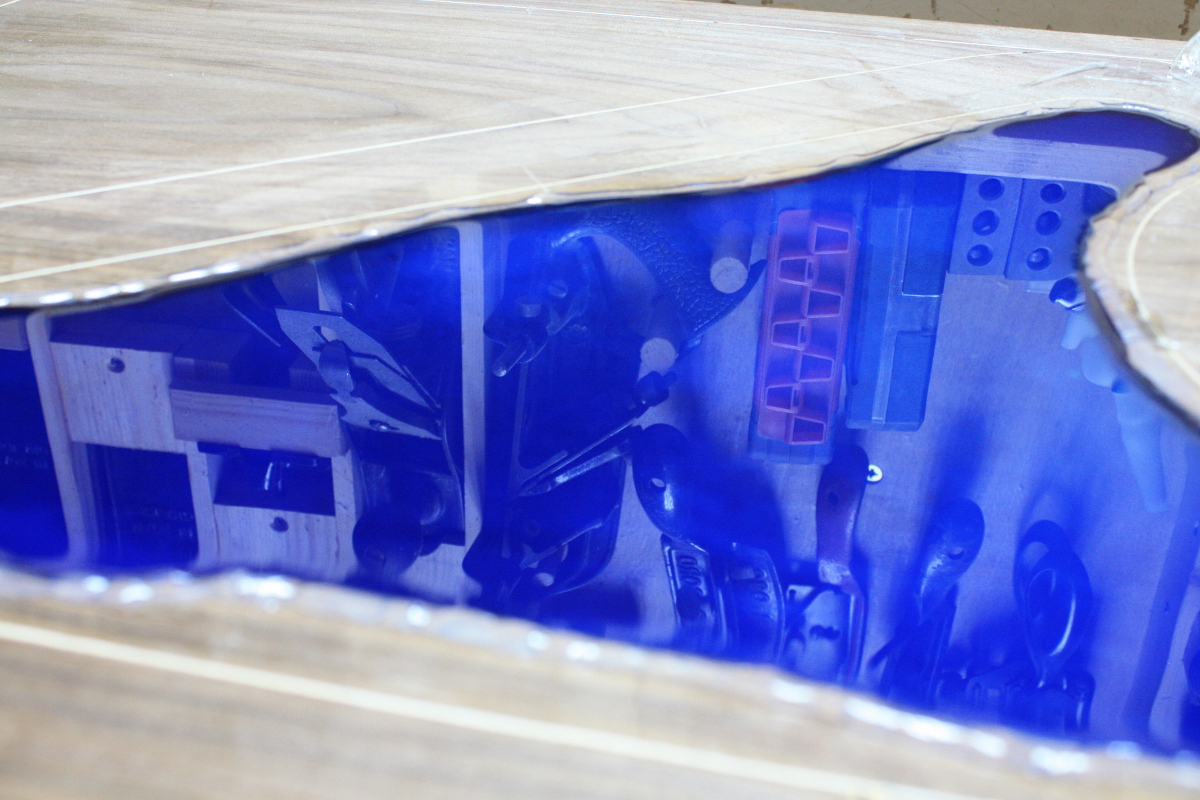

And then I started to mix resin and pour it with the aid of a consultant.

As the consultant has been learning in Octonauts, the sea has three layers, starting with the Midnight Zone which is not only very dark but also hides the holes and gives a nice appearance of depth…

Then comes (an hour later) the Twilight Zone...

Liking that variation in colour there (this is completely flat, it's entirely down to the colour of the bottom layer). Next comes the Sunlight Zone...

It wasn't

quite deep enough though...

So another layer got poured, after building a hot-glue dam.

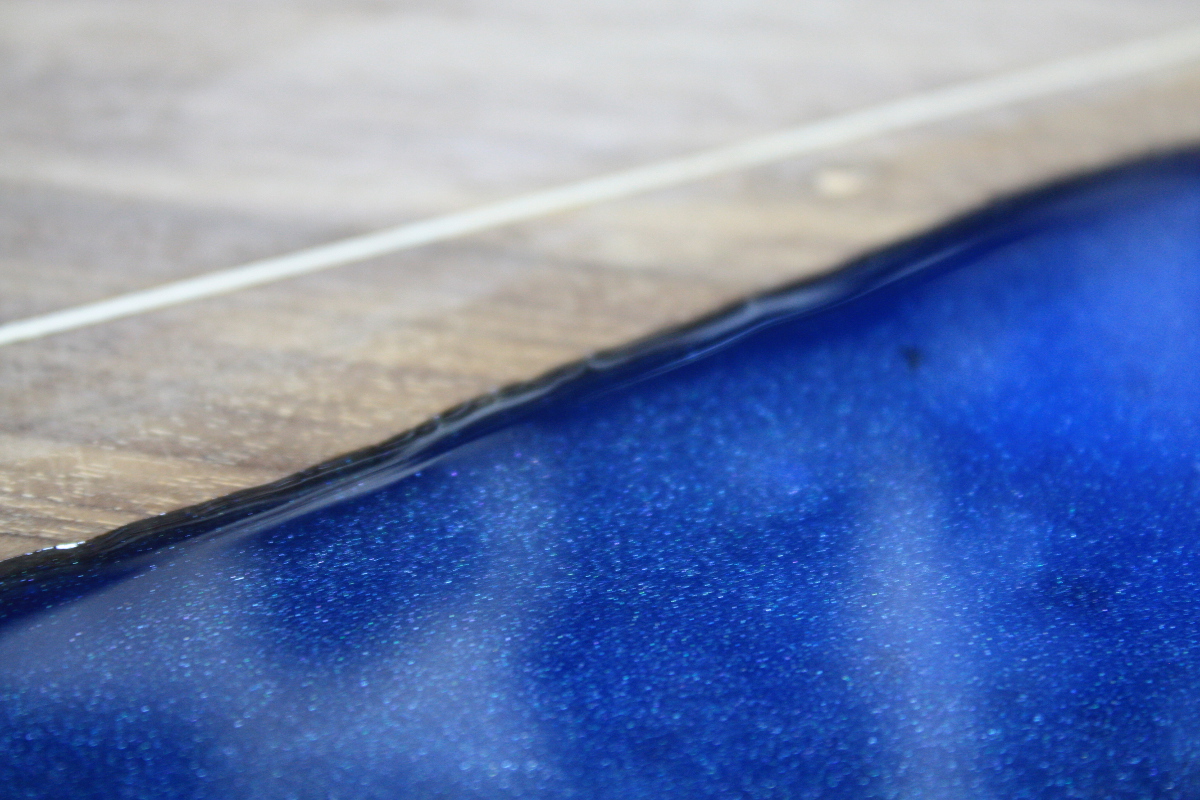

I hate that mirror finish because I know I can't sand back to it

I know this because I tried. I was sanding for two weeks in total. Resin clogs sandpaper almost immediately. Even my new toy was no help.

In fact my new toy was terrible because it has a velcro pad for the sandpaper and clips if you don't have the velcro type of sandpaper, but if you don't watch it, you can get the sandpaper aligned badly in the clips and the velcro hooks dig into the resin and leave these very distinct trails that you can't sand out later and you have to pour another thin layer of resin over the top and then sand that back and THERE SHOULD NOT BE THIS MUCH SANDING DAMMIT I GIVE UP GIVE ME THE #080 I DON'T CARE ANYMORE....

Wait a minute. What the hell do you mean you can scrape resin? What did I just waste two weeks on... ffs...

And the dust. I didn't seal the pores of the walnut...

Crap. I tried hoovering it out. No dice. I tried flushing it out with white spirits. Nope. Also, do that outdoors, that stuff in a small shed is... well, it's interesting. That's danish oil thinned with turps in the photo, I was hoping that it'd penetrate down and wet the dust.

I mean, kindof. A few coats of that plus the poly over the top might solve the problem... sortof... but basically at this point I think I'd screwed up the finish beyond the point of repair for the "fine furniture" category. Happily, I think the joinery kicked us out of that category a while ago, so on we go and we'll make the best of it.

At least the underneath looks nice...

Next up, the LED recess. Again, this was a router job. I gritted my teeth and got on with it, and the results were not too bad.

I then discovered I didn't have a hacksaw to cut the alumium extrusion with. I don't know where it's gotten to, I know I used to have one. Oh well, spinning screaming finger eaters that try to set the shed on fire by spitting sparks everywhere it is...

I mean, I think it was overkill as well, but I was sortof out of options. A bit of filing and I had something more usable.

Hooray for endcaps, they cover up a thousand sins.

I did have to dig a bit deeper at one end of the channel for the wiring.

And then I am pretty sure I over-spec'd the drill bit for the job. I mean, I know none of mine would have done the job so I had to buy something, but this just looks like I'm compensating here...

Still, did the job.

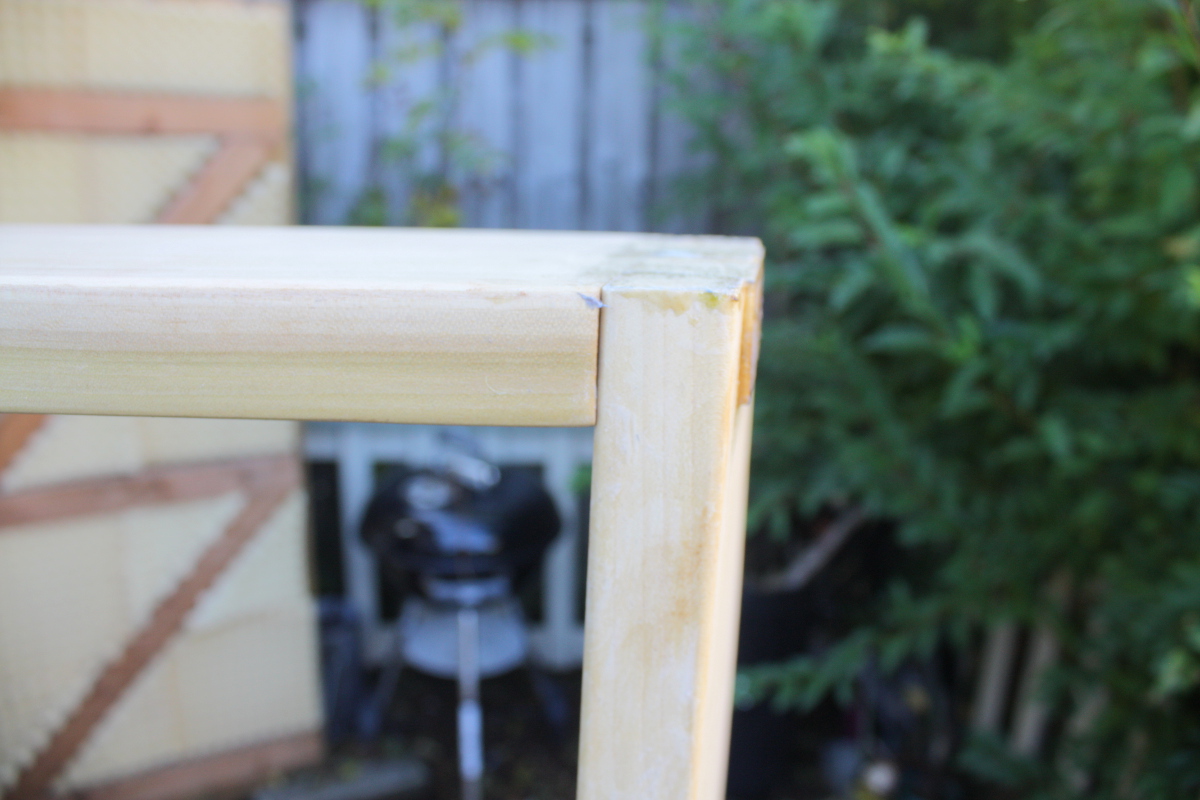

Next some handplane chamfering of the bits of the uprights that will sit against the wall so that they sit flat...

And that was the last really big job. So out came the #04 and my favorite preston spokeshave and I finished the final shaping of all the edges so they were nice and round and then I tried cleaning up all the flat surfaces. I say tried because the project has been sitting in a very small shed for many months and some of those boards had taken knocks and dings in various places and despite steaming they wouldn't recover

This is one of the many, many, many,

many downsides to working in too small a space

I wanted to pre-finish the boards because it'd be easier to get undersides and stuff now, so I gave them all a coat or two of danish oil first (thinning the first coat 50% with turps) so they'd have some colour.

Those tanlines from the pack's straps are still clear as day. Le sigh. Time and UV should fade them, but that is somewhat annoying.

And for the protective layer I wanted a polyurethane type of finish, but the only brands I know are american. This osmo polyx stuff had good reviews, so I'm taking a chance on it. One thin coat now, one thin coat when assembled and glued up...

For a transparent finish, that's a funny colour, but if you keep the coats thin enough it works...

I really really want a bigger shed with a proper assembly table and drying area...

Right. Now the day I've been dreading since I designed this thing. Glue-up.

That was the single most awkward, most nervewracking glue-up yet. All hide glue to get the most open time. Some of the boards had warped just a little bit - a mm or two over the full length of the uprights - so it gave it that extra little

frisson trying to get it together as the glue went tacky. And the housing joints did not fully seat at the back which ticked me off no end. But - the sliding dovetail was the right idea, it worked nicely and the whole thing did come together with only a bit of clamping force. And a lot of swearing. Sooooo much swearing. Not all of it in english.

The dovetails even came together reasonably well.

And left to cure for a few days in the shed, now eating ALL the floor space.

Seriously, what was I thinking? Way too big for this shed.

Next, I got the LED strip (warm white 5050s if anyone's interested), cut a length off the reel, soldered on a wire, stuck it inside the extrusion (the strip is self-adhesive), added some heatshrink tubing for sealing and strain relief, hotglued the wire and the endcaps in place and left it at that until final assembly.

Then I rounded over the dovetail joints and tidied up the corners a little.

And reoiled those with danish oil. A few days later, I very awkwardly carried the whole piece outside again (I was working at home so I used my lunch break) and gave the whole thing the second thin coat of polyx:

And then a few days later I used hide glue to stick some leather pads to the uprights where they meet the wall to try to prevent them from tearing

all of the paint off the wall.

Yeah, I might have just given up on the clamping there and figured that if hide glue will hold a rubbed glue block in place against gravity, a rubbed glue joint and some tape would be fine for a light piece of leather.

And then today, while Calum was out at a birthday party (kid's got a better social life than either of us), I snuck out, trimmed the leather with a sharp chisel, dragged the piece indoors, fitted the LEDs, soldered the socket for the power supply to the LEDs, and put it in his room.

His knees still fit under it (and the growth charts and

The Woodworker's Guide to Furniture Design say we get another two years before I need to put the whole thing up on blocks).

Lighting works...

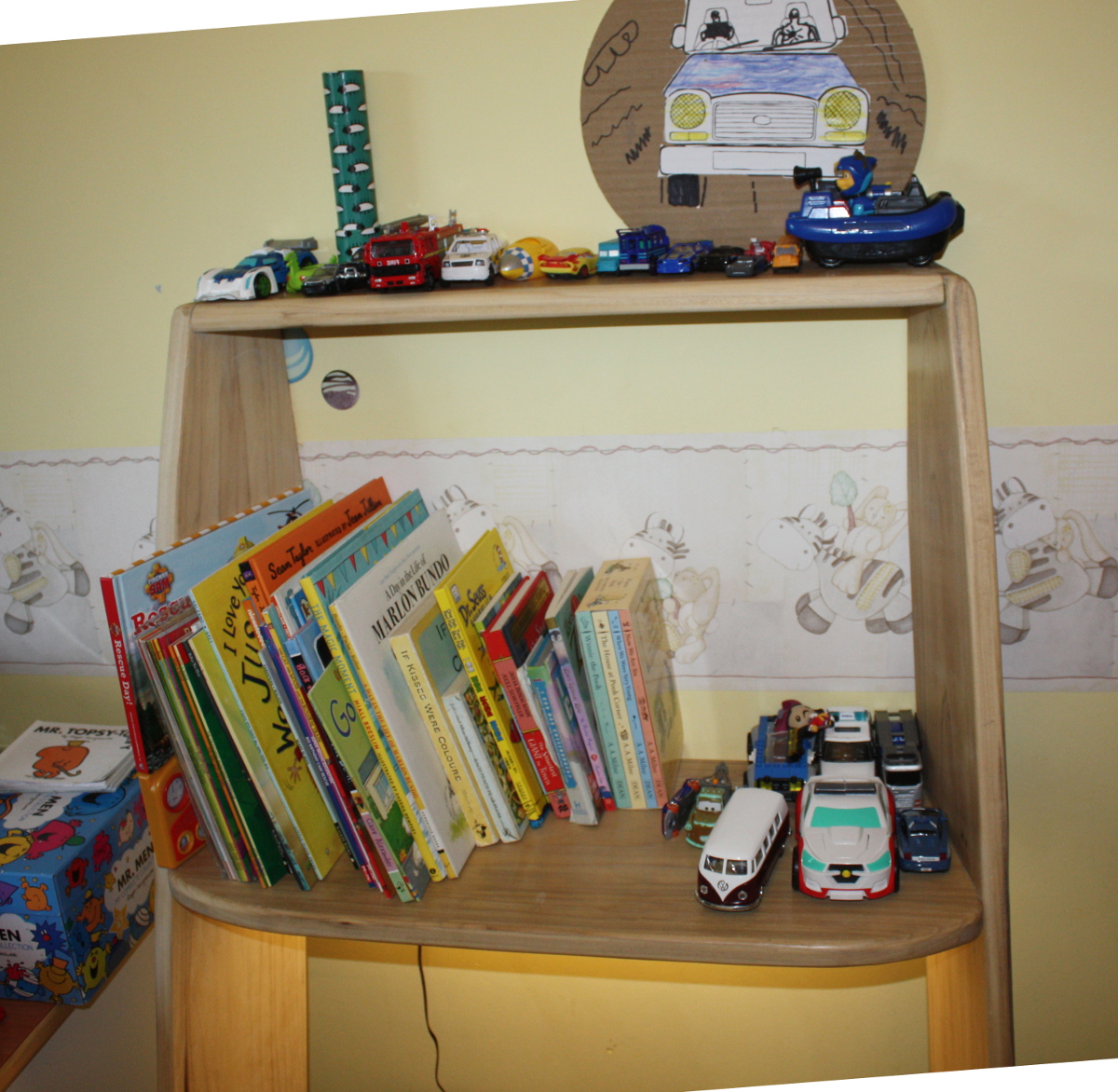

He immediately stocked it with all the toys, but it's a bookshelf so Herself intervened...

He doesn't realise it yet, but this desk is destined to be a desk of homework and woe, but for now...

Okay, maybe a

little bit of woe...

Yes, that is the Titanic. Yes, he did make it himself. And yes, he does love playing

sink the Titanic and everybody drowns in the North Atlantic. No, I don't know why. I'm sure it's nothing to worry about...

Cleanup, on the other hand... that may not be finished until xmas...