wallace

Established Member

Thanks Jim. I'm doing all the little bits now and I'm very nearly finished.

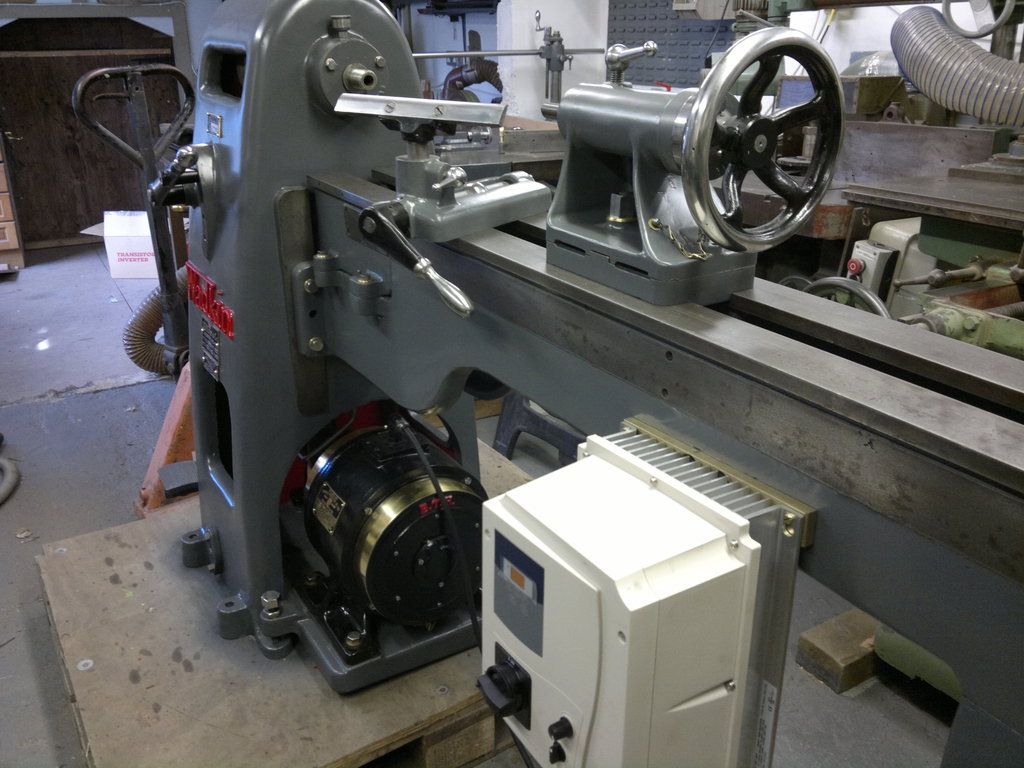

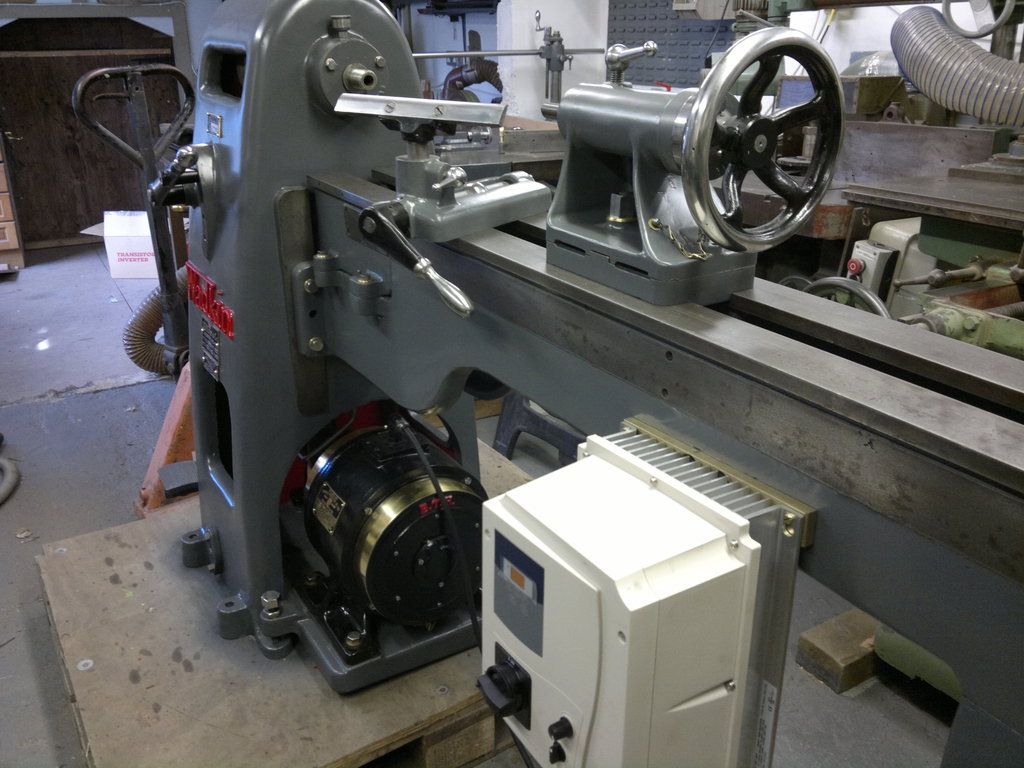

I have made it so the VFD can be unclipped and moved to the outboard end

Heres a clip of the lathe running for the first time

https://www.youtube.com/watch?v=_ckvCjD ... drLoCMqmqg

I have made it so the VFD can be unclipped and moved to the outboard end

Heres a clip of the lathe running for the first time

https://www.youtube.com/watch?v=_ckvCjD ... drLoCMqmqg