wallace

Established Member

The crown guard had some holes drilled into it and some damage, so I thought I would try and braze it.

As I was brazing I noticed a hair line crack appear. I think it would of been better doing it with the mig using bronze wire, then their wouldn't have been so much heat.

A bit fugly

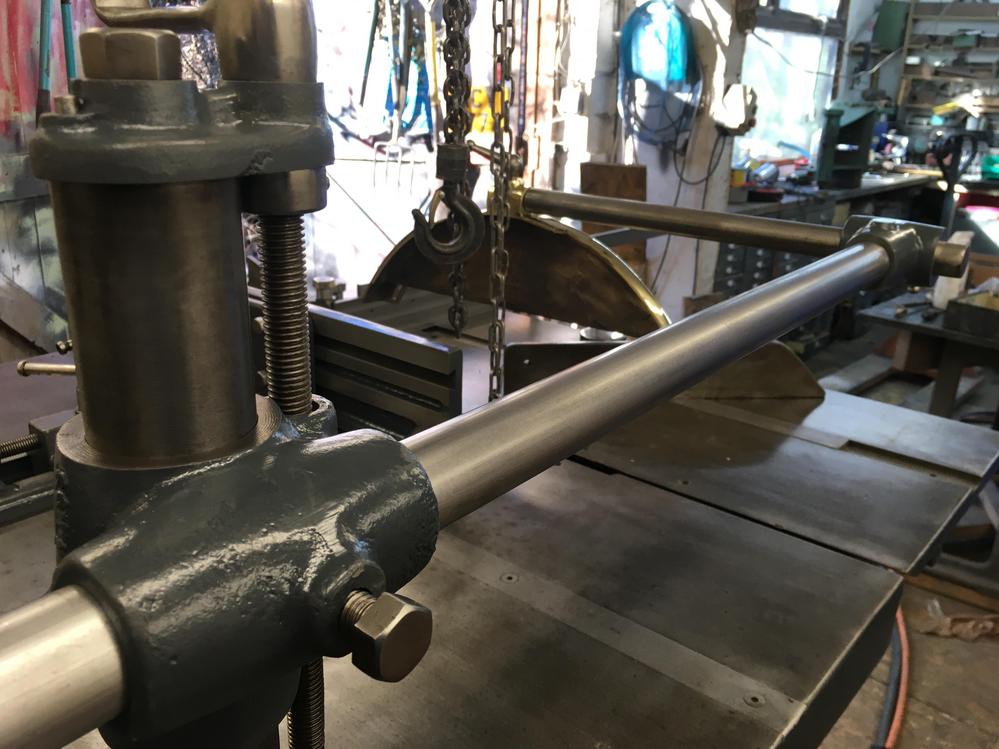

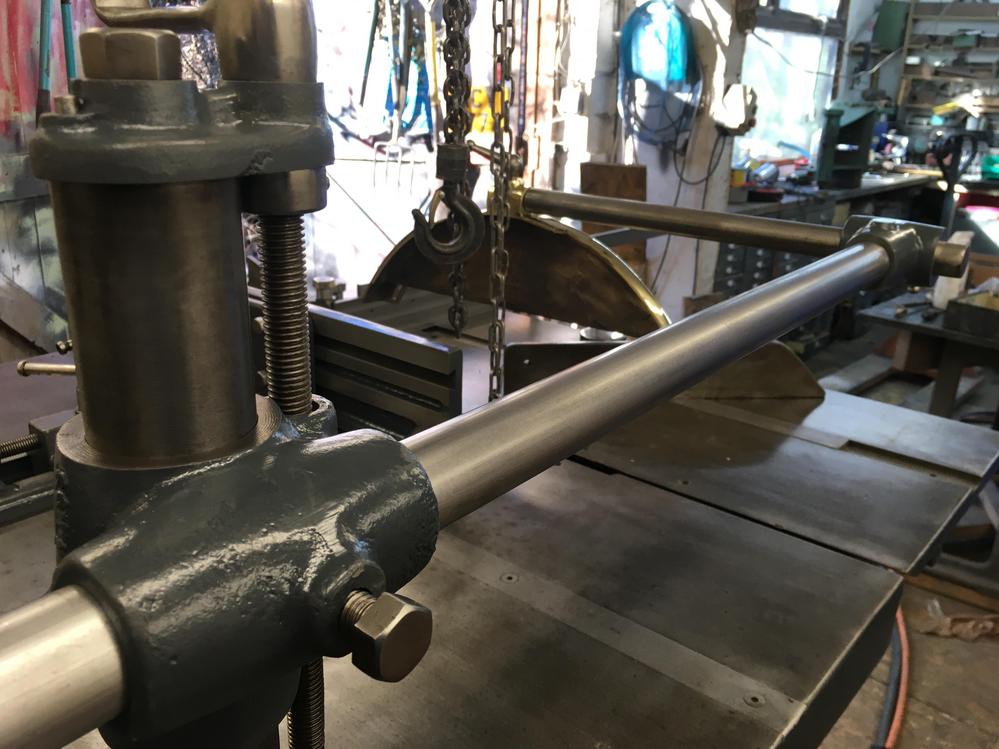

The nose piece was missing but I had one in my stash.

This must of been off a smaller saw because the bar is too small for a pk, luckily again I had a longer one in my stash

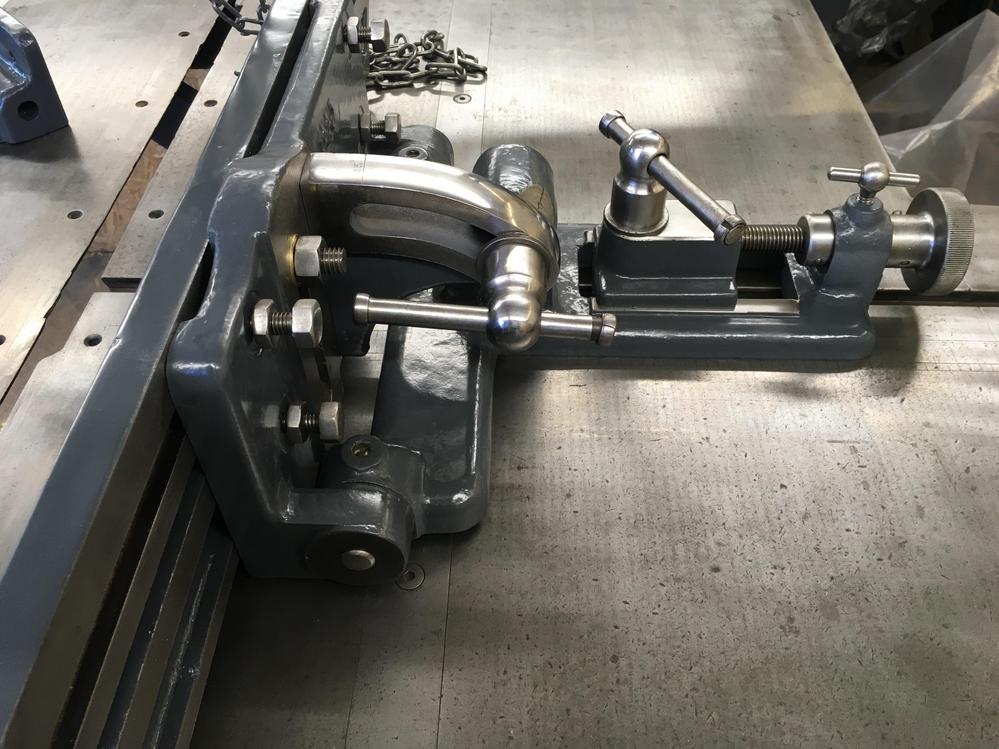

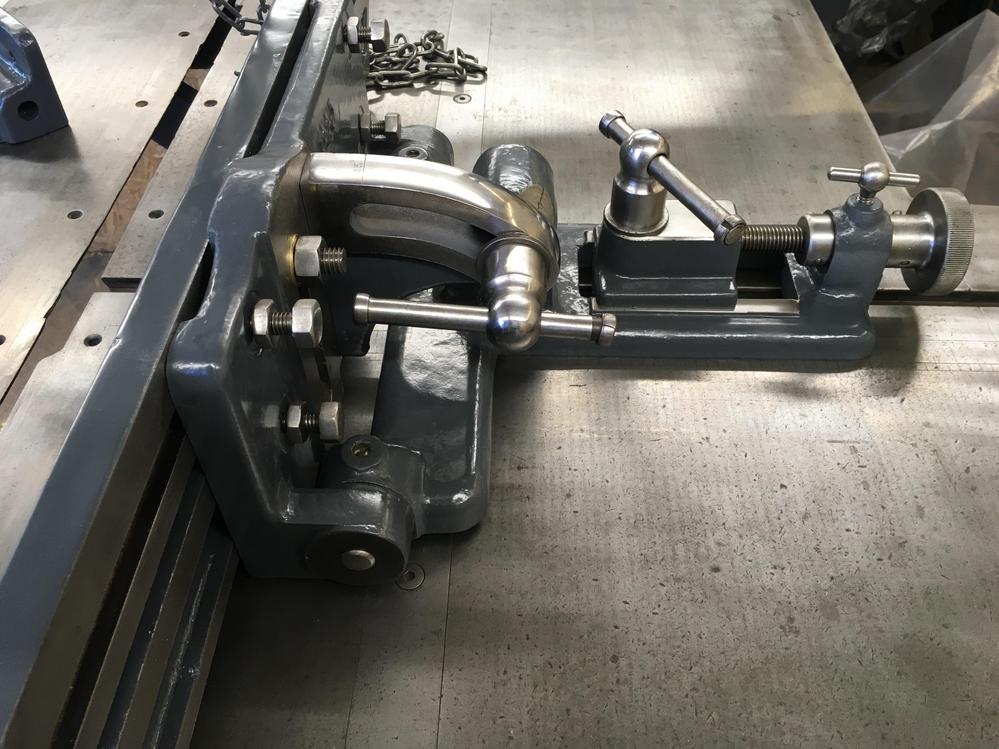

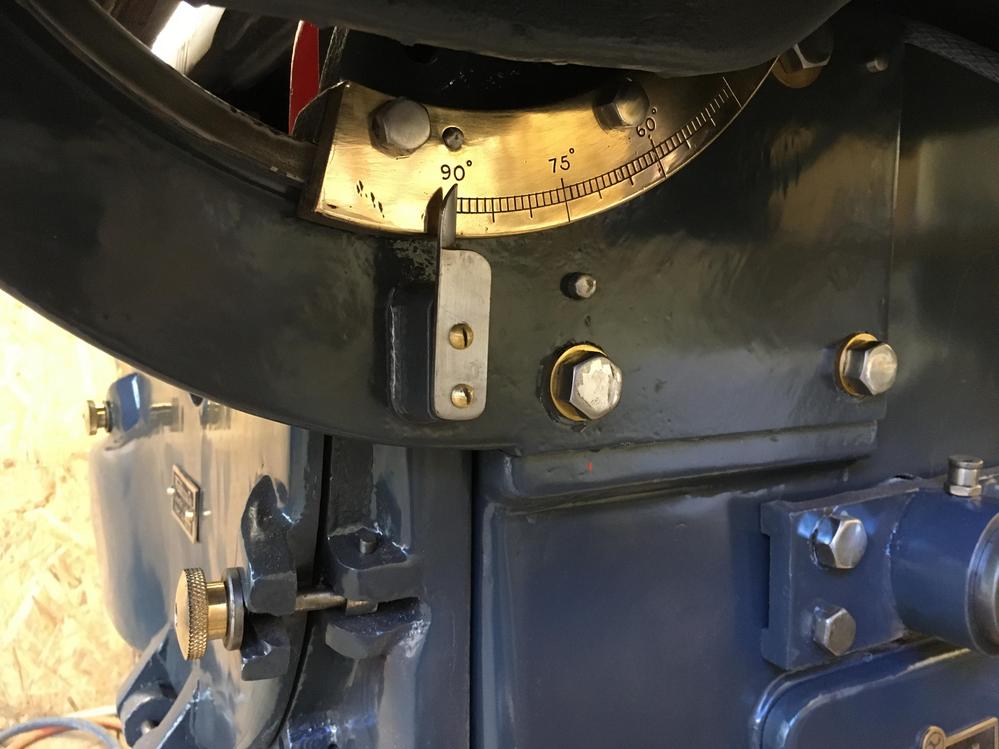

I needed a table stop for the slider

The knurled knob is not my work, I had a batch of them done off doubleboosts pal who does the cnc stuff

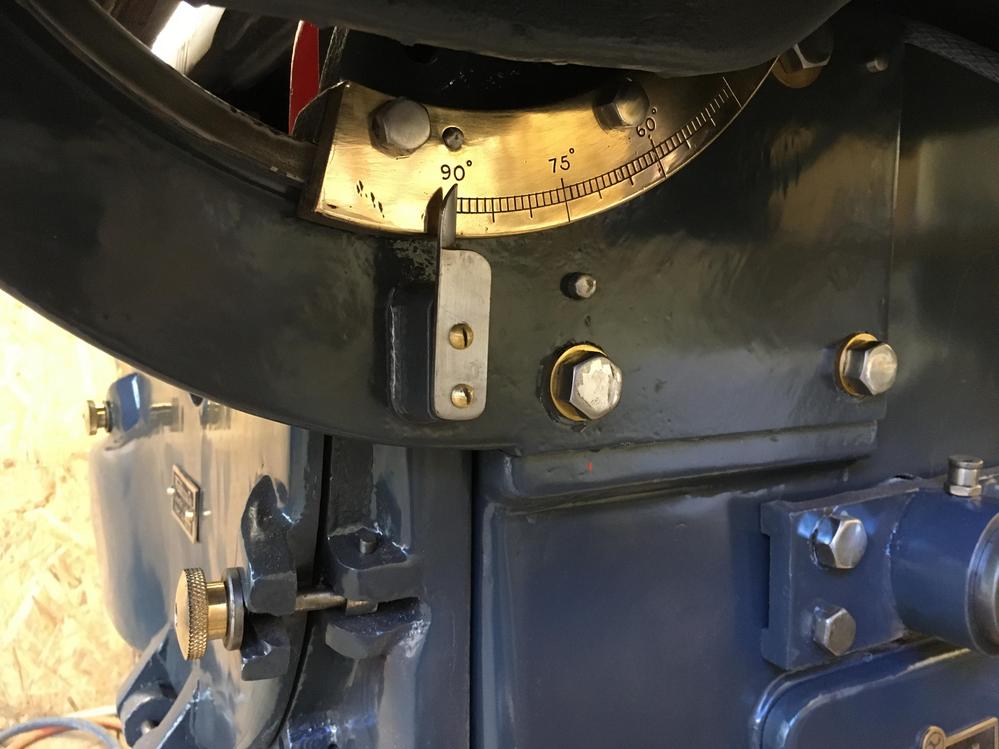

No presests in the table

As I was brazing I noticed a hair line crack appear. I think it would of been better doing it with the mig using bronze wire, then their wouldn't have been so much heat.

A bit fugly

The nose piece was missing but I had one in my stash.

This must of been off a smaller saw because the bar is too small for a pk, luckily again I had a longer one in my stash

I needed a table stop for the slider

The knurled knob is not my work, I had a batch of them done off doubleboosts pal who does the cnc stuff

No presests in the table