Steve Maskery

Established Member

Hi all,

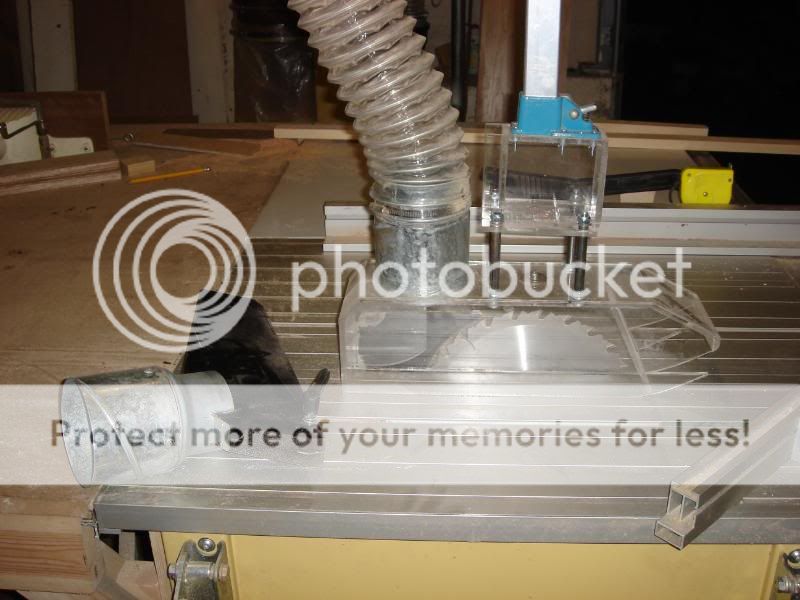

For some time I've been thinking of making a better blade guard for my TS. It's a trad conventional crown guard, cast metal and bright yellow for visibility but its good points stop there really.

I fancy trying to make a SUVA-style guard mounted on the back rail somehow, but I want it small and compact.

I was wondering if anyone else is thinking of doing the same and would be interested on collaborating on a design, or at least swapping ideas?

On a related note, this simple guardby Charles Neil looks like a useful addition for anyone with an old saw that is unguarded. I found this video clip as he is using the same principle for cutting thin strips as I use in my jig. It comes up in Related Videos.

Cheers

Steve

For some time I've been thinking of making a better blade guard for my TS. It's a trad conventional crown guard, cast metal and bright yellow for visibility but its good points stop there really.

I fancy trying to make a SUVA-style guard mounted on the back rail somehow, but I want it small and compact.

I was wondering if anyone else is thinking of doing the same and would be interested on collaborating on a design, or at least swapping ideas?

On a related note, this simple guardby Charles Neil looks like a useful addition for anyone with an old saw that is unguarded. I found this video clip as he is using the same principle for cutting thin strips as I use in my jig. It comes up in Related Videos.

Cheers

Steve