swagman

Established Member

Hi Jimi. When you wake up you will have some interesting photo's to look at.

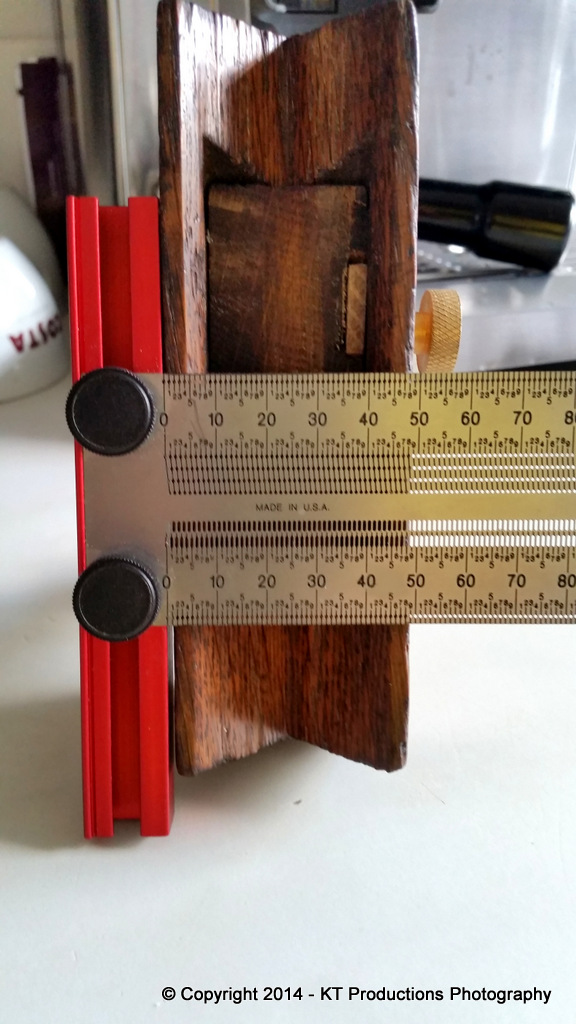

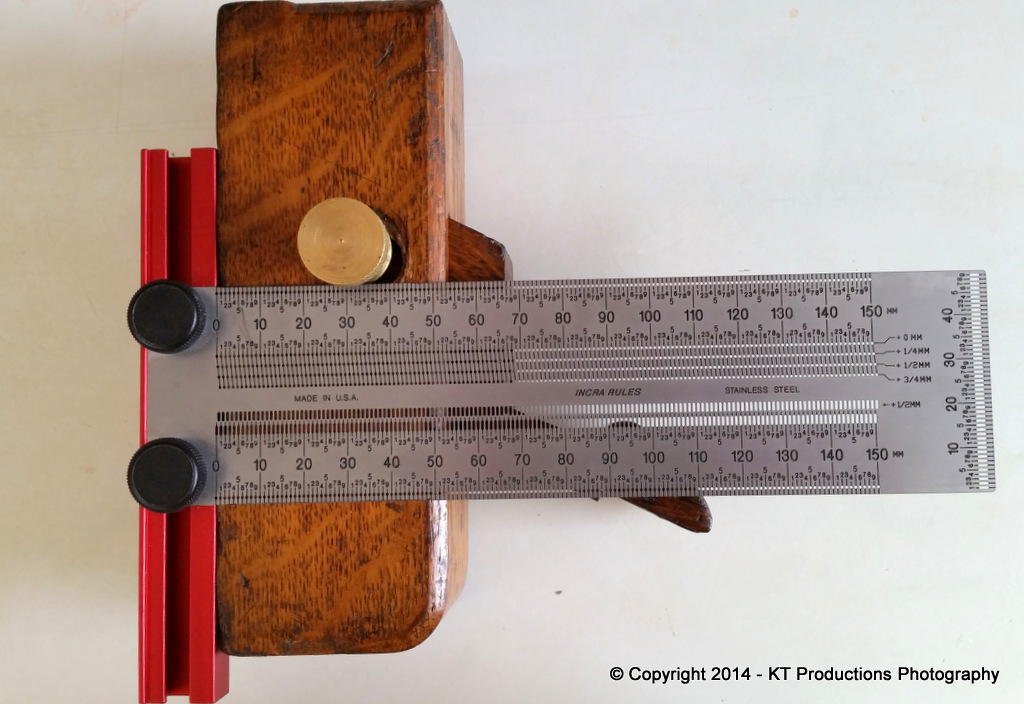

The following is the completed boxed chamfer plane. Its had it last coat of shellac and received its final sanding. I will need to wait a couple of days to allow the shellac to harden before I can add some shine to it.

When chamfering the edge the shavings tend to be quite stringy in form. As such the boxed chamfer plane does requires a fairly generous mouth opening to allow these shavings to pass through unabated to the throat area.

I have also added a brass piece between the upper tines of the wooden box to prevent later inward creep. An issue I noticed on some of the earlier made chamfer planes of this type.

I added a bevel the lower edge of the brass brace to deflect the shaving..

And lastly a brass impact area on the back end of the plane to save damaging the wood surface.

Now for testing the chamfer plane out on some Australian Blackwood and some ****** grained Cypress. The stop was set for a 12mm wide chamfered and the cutting irons cutting edge set at around 0.5mm .

The 2 chamfers looked very good on consistent width and clean cut finish.

regards Stewie;

The following is the completed boxed chamfer plane. Its had it last coat of shellac and received its final sanding. I will need to wait a couple of days to allow the shellac to harden before I can add some shine to it.

When chamfering the edge the shavings tend to be quite stringy in form. As such the boxed chamfer plane does requires a fairly generous mouth opening to allow these shavings to pass through unabated to the throat area.

I have also added a brass piece between the upper tines of the wooden box to prevent later inward creep. An issue I noticed on some of the earlier made chamfer planes of this type.

I added a bevel the lower edge of the brass brace to deflect the shaving..

And lastly a brass impact area on the back end of the plane to save damaging the wood surface.

Now for testing the chamfer plane out on some Australian Blackwood and some ****** grained Cypress. The stop was set for a 12mm wide chamfered and the cutting irons cutting edge set at around 0.5mm .

The 2 chamfers looked very good on consistent width and clean cut finish.

regards Stewie;