Right, where were we? I've had a good couple of days in the workshop, so I've a little progress to report. Previously, I'd got the bare shell of the corner unit in:

The next step was to make the face frame, but this had changed a little since deciding to use the bottom of the cupboard for my vacuum cleaner. It had to be really narrow to allow the thing to fit through, so I decided to rip the two pieces out of one ex 2"x1" PAR. The junction angle is 22.5 degrees. I hate moving my bandsaw table as restoring it to square is an absolute nightmare. Still, it seemed a better idea than ripping this by hand:

I made a piece to capture the top end:

....and I was really pleased with the edge-join:

Here it is finished off at the bottom, and with a skirting:

Next up, the door. Firstly, I painted a couple of ply panels:

Then after cutting the stiles and rails to length, I routed a groove. note the stiles have the groove continuing around the end of the board (and they go down the other side a little way). This is the easy way to set out a bridle joint:

Here's the tenon (6mm wide) set out:

As this was really nice straight grained wood, I decided to chisel away the waste for the tenon, rather than sawing it. It's quicker and generally more accurate in co-operative timber:

That's done entirely with a chisel.

The central rail has a tenon only 10mm long either end, just sitting in the groove:

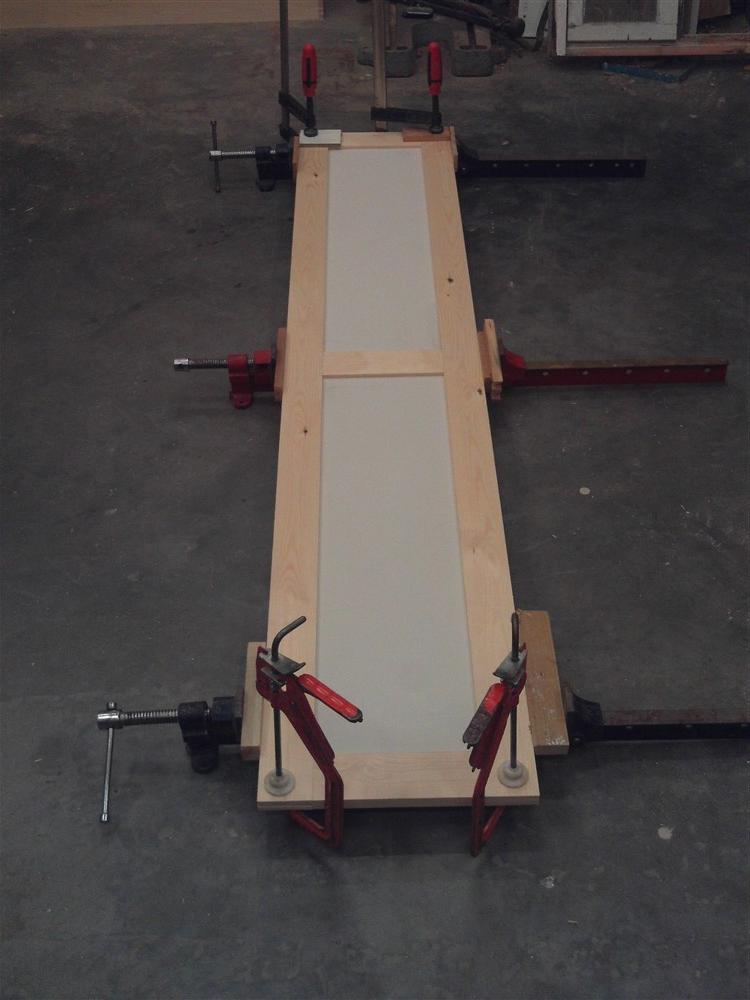

It was soon glued up:

I popped up the "cornice":

Whilst the door is drying, time to take a look at this hell-hole at the end of my bench by the workshop door:

That's an old bookshelf just stuffed in there and used to hold packing pieces for glue-ups, and some home-made loose tongues/ biscuits:

That needs sorting. So does this:

With the shelves moved, all my tool cables trail all over the place across the shelves, and just get in the way. The sockets need to move.

I gave the shelves some attention, adding a bottom shelf and some upstands to the front edge to stop everything spilling out. Then I moved it to the other end of my bench:

Soooooo much better at the door end:

I also made a quick little holder for my new glue-up clamping triangles:

Note the new downstand piece below the bottom shelf:

After a fiddle re-routing cables, it had certainly fixed the problem. All my power tools can remain permanently plugged in and accessible. note also the switch on the right of the corner cupboard. This is a double pole fused spur isolating switch, switching a socket inside the cupboard. Now the vacuum can be used without opening the cupboard door:

I hunted around through my collection of old panels and doors, and found this:

Perfect! I trimmed 10mm of each side, and cleaned it up a bit, then made this from it:

Those are my most commonly used workshop jigs.........bench hooks, shooting board, and belt sander stand, and they've just kicked about on the floor for years.

I then hinged this carefully shaped piece onto the bottom:

.......and fitted it into the gap between my tool cabinet and the corner cupboard:

After fitting a shelf over it, I took it away for painting, and returned to the cupboard door. Here's the first fitting:

Then with butt hinges let into the edge, and a handle & catch added:

I then fixed in permanently the jig-holder:

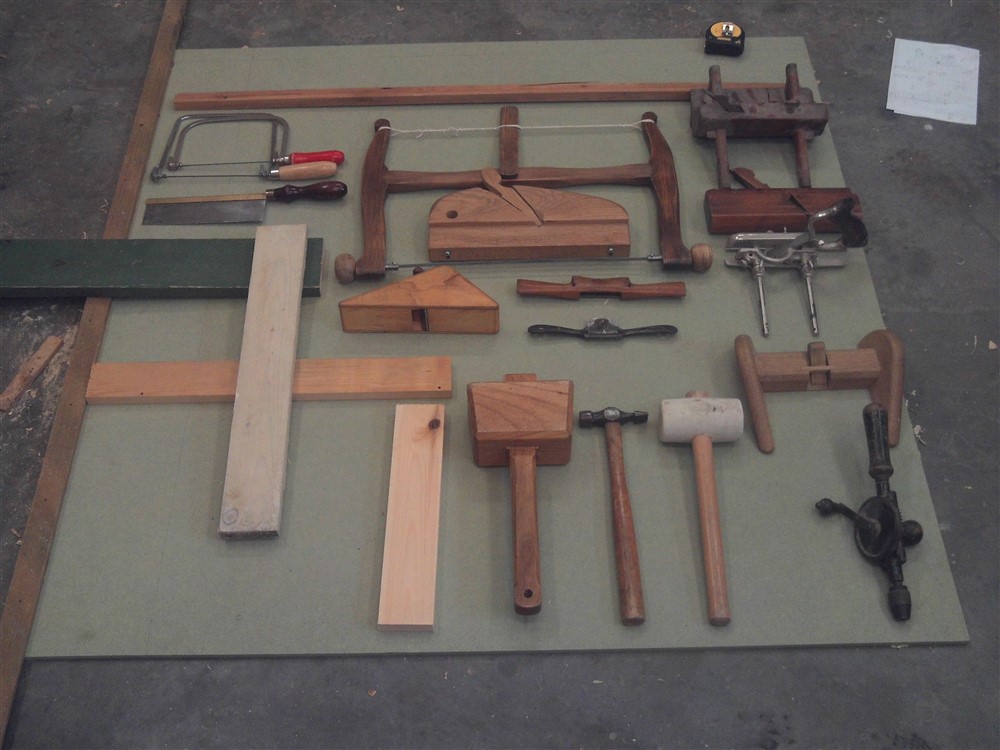

Now, at last, I could turn my attention to getting my tools sorted into the cabinet. I started by laying out a sheet of MDF on the floor and demarcating an area the same size as the tool cupboard main compartment. I made a schoolboy error, which wasn't to show itself for a little while:

The biggest thing in the cabinet is going to be the saw storage, so I started with that. I shoved a load of stuff out of the way so I could use my radial arm saw, and made a series of 3/4 depth cross cuts. Chamfering always make things look a bit more interesting:

I was really please how well this nasty cheap 1/2" ply took the screws holding this in place:

The dowel at the bottom is self-explanatory:

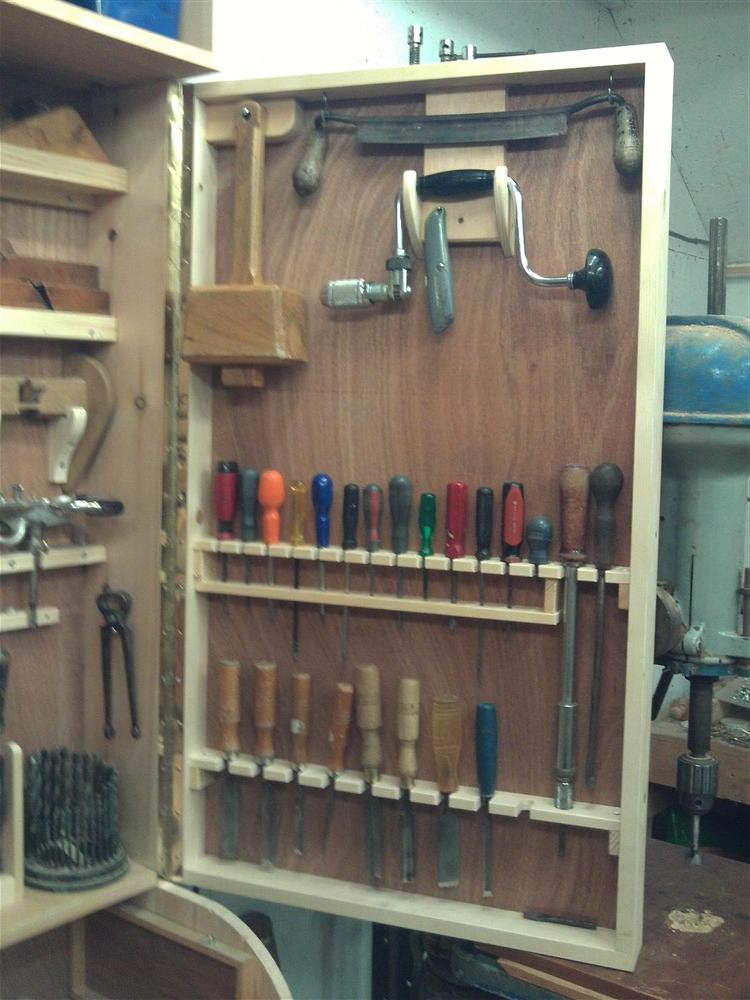

At this point, I discovered that the tools above the saw till wouldn't fit as planned. After a bit of measuring and head-scratching, it turned out that I'd laid the board out portrait rather than landscape. Twerp. So, I quickly re-arranged:

......and got this far before my wife returned after a weekend away, and work stopped: