Using the last shelf left over from the original shelving unit, I made a shelf for the upper cupboard. This will be hidden behind doors:

I thought I'd quickly do the piece covering the junction with the ceiling. In for a penny, in for a pound.......so it's dovetailed too:

As the longer piece across the front is about 1200 tall, I had to clamp a piece of scrap in place so that the tail board had something to rest on when marking out for the pins:

The original shelves yielded up a reasonable amount of easily re-usable timber, but they also left these pieces:

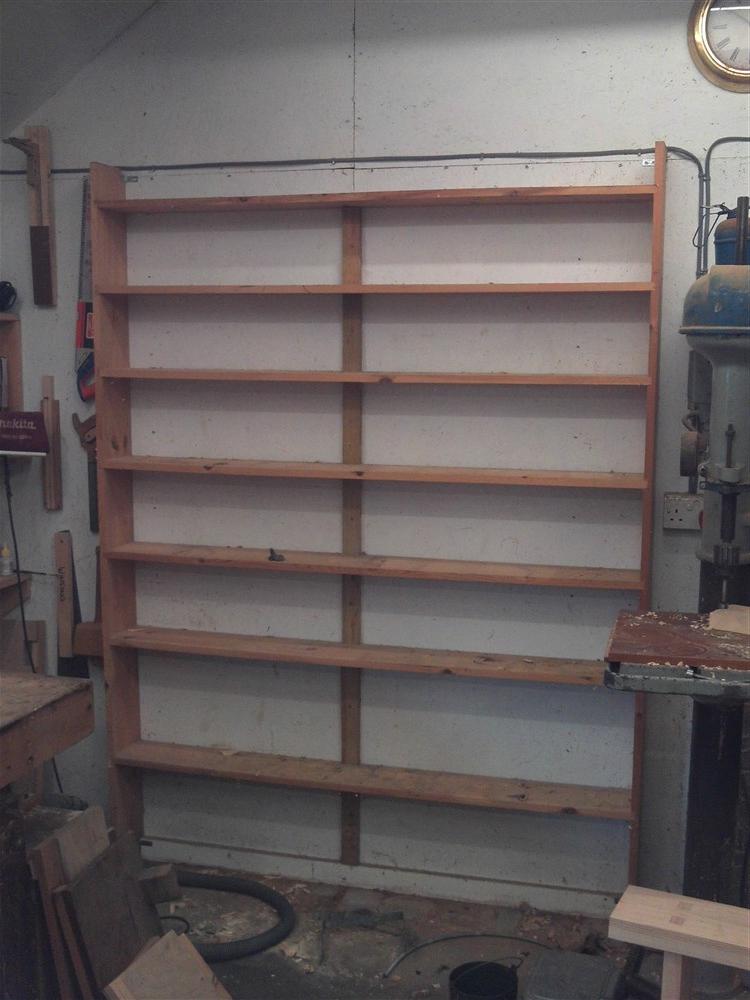

Those are the original sides, from here:

Well, I got to thinking, and decided to re-use them for pretty much their original purpose, but as part of a corner cupboard. That is why I had glued these boards together yesterday:

So today I de-clamped them and started marking out then sawing:

The problem I am trying to resolve is this hell-hole at the end of my bench:

Apart from the vacuum cleaner there are various jigs, bench hooks, shooting boards and so on, a vacuum drop-box, and all sorts of detritus which falls from the end of the bench. When I started looking at the shelf spacing on the old cheek pieces, I had the brainwave of having the vacuum cleaner sit in the bottom of the cupboard, with the hose projecting through side-wall. This meant adding one extra shelf position:

I calculated that I needed to remove 8.3mm from one edge of the side boards to obtain the necessary angle with the front to make a 135 degree junction, so I set that on the calipers and then used them as a marking gauge:

I then planed down to that line (using a number 6 Record, for those who like to know this stuff):

I'd previously cut the corners off the big triangles, and cleaned them up ready to fit as shelves. Now I glues and screwed them into the housings in the old side-pieces:

Those intermediate shelves are set a few mm back from the inside face of the face frame. The top and bottom will be different though, so I left them out at this stage. Here is what the corner cupboard will look like: