Sportique

Established Member

Help please.

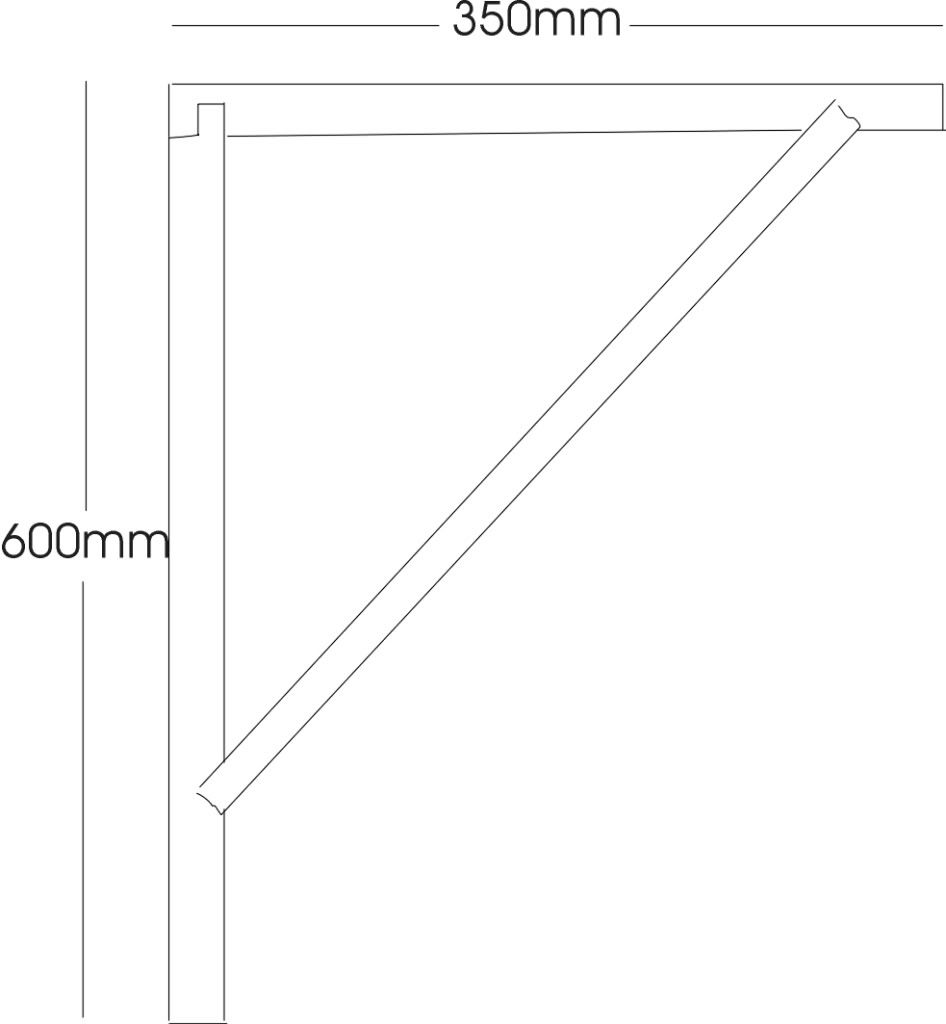

I need to make some timber storage racks for length material not sheet.

I have decided on the following sizes:

Overall length: 2400mm

Width: 350mm

No of brackets per 2400 run: 5

Bracket spacing: 600mm

BUT - how to form the brackets using (for example) studding, able to bear the weight with relatively simple joints. I have come up with this idea, but PLEASE improve it :roll:

I plan to use just the supports, i.e. no shelf material (the stored timber itself will form the "shelves")

Unable to guess at the weight but timber is heavy! :?

Any suggestions much appreciated, thanks in advance

Dave

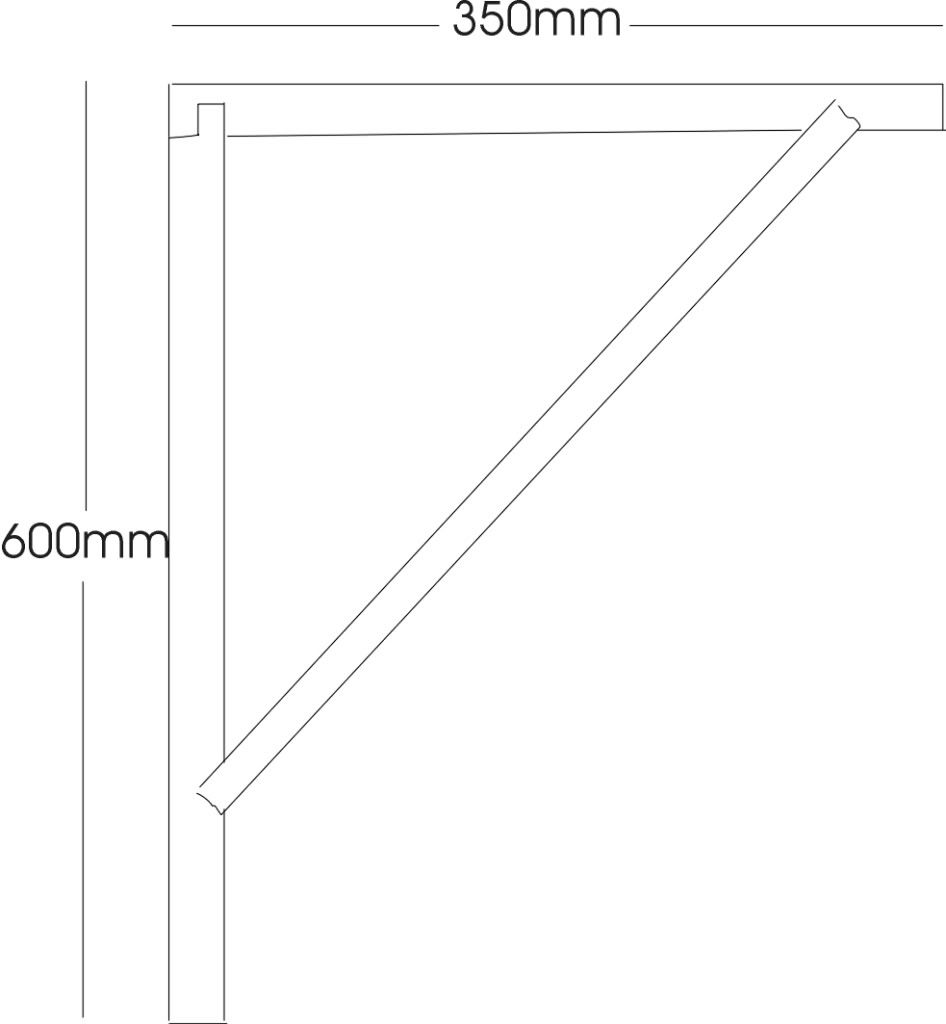

I need to make some timber storage racks for length material not sheet.

I have decided on the following sizes:

Overall length: 2400mm

Width: 350mm

No of brackets per 2400 run: 5

Bracket spacing: 600mm

BUT - how to form the brackets using (for example) studding, able to bear the weight with relatively simple joints. I have come up with this idea, but PLEASE improve it :roll:

I plan to use just the supports, i.e. no shelf material (the stored timber itself will form the "shelves")

Unable to guess at the weight but timber is heavy! :?

Any suggestions much appreciated, thanks in advance

Dave