Jacob

What goes around comes around.

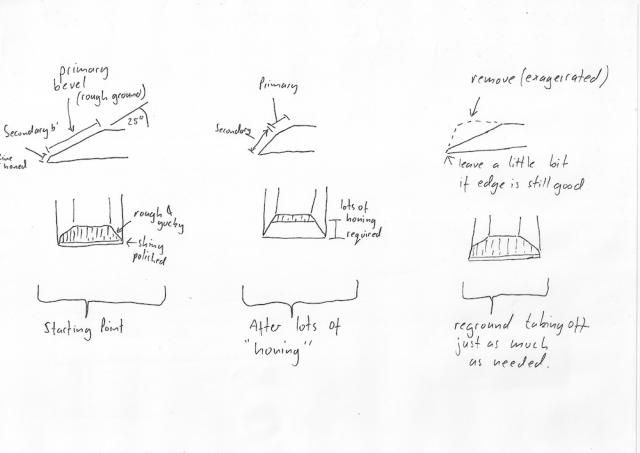

Not if it's blunt, which is presumably why you are sharpening it in the first place. In which case just grind it off - only just as far as necessary, and be careful of overheating.RossJarvis":3etem5ra said:.... However there's no need to rough grind all of the secondary bevel off, as the cutting edge will hopefully still be pretty sharp. ....

It may be necessary to go well past the original bevel if the face is also worn.

Honing a nicely ground new edge is the work of seconds. It gets progressively more difficult as the honed area increases, whether as a rounded or a flat bevel.