Okey dokes then here goes!

Having obtained about 20 cubic feet of Sapele a few weeks ago from a supplier I use in Snetterton I decided to pre-thickness a large quantity of the 1" sawn stock to save time in the long run.

The widths of the boards varied from 150mm up to 450mm wide so I sorted them into the varying widths, leaving the widest of the boards to use last

I started by try jointing up the boards for the two outer sides and having been biscuited they were glued up and left in the cramps when I left this afternoon to allow the glue to fully cure - Titebond original used as usual

With the large boards made I started on the components for the upper and lower frames which were easily cut having already been thicknessed

The frames for the tops and bottoms will be rebated for ply panels to be fitted into after construction as this will have to be made in component form as in my usual style this one again has to go up a spiral stair case in an old Norfolk Cottage. Where normally I would look to pre-rebate the components and then cut off-set shouldered mortice and tenons I decided to simply M & T the frames and retro cut the rebates with a router after they are glued up.

Cutting the mortices

Removing the haunches from the tenons on the bandsaw - note the piece of waste plywood under the tenon to prevent the off cut from dropping at an angle between the fence and blade pushing the blade out and into the shoulder of the tenon.

With the waste removed a clean up with a chisel was needed to even the shoulder from the bandsaw cuts

Before I chamfered the ends of the tenons with a chisel and plane - I do this for two reasons,not only does it make assembly easier but also overcomes the uneven edges in the bottom of the mortice hole left by the hollow chisel bit

The eagle eyed amongst you may spotted the chisel in the background that I am using - Its one of Rob Lee's Veritas chisels which I am currently using to formally review - I have got to say they are very nice! - Full review to follow

So when I left today the main frames were cry assembled and a good start made

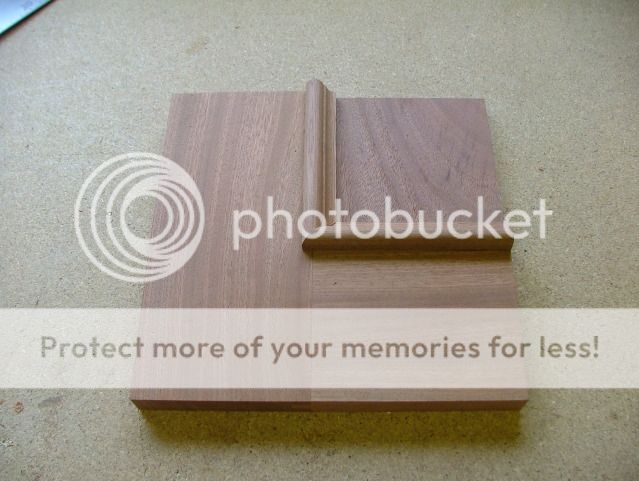

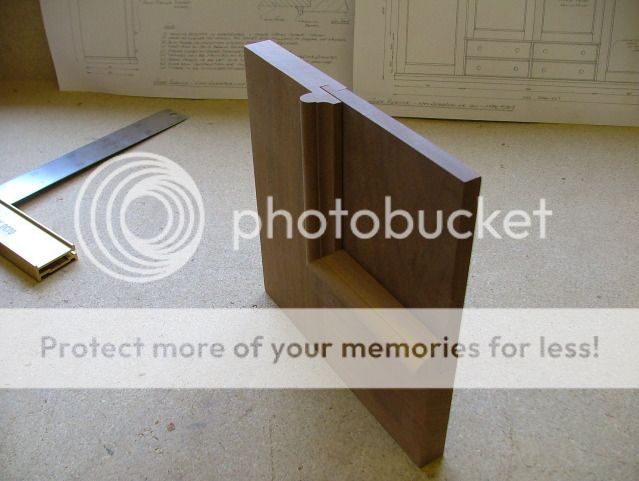

The basic construction of the carcasing is relatively straight forward but the doors will be a little more unusual with the traditional wide rails and stiles, with flat panels and raised edge beading - the photos below show the samples that were made for the client prior to the commission being confirmed.

Doubt I will get much done tomorrow as off to the Midlands to pick up a new toy for the workshop but will update again on Thursday