goldeneyedmonkey

Established Member

Hello folks,

I bought the aforementioned SCMS from Ebay, nearly a month ago. But I've only just now had a a chance to fully test it out.

I tried the motor as soon as I got it, it worked fine. But now after I've tried to slide the blade along the full length of it's travel I found it to be very difficult to do, it's not smooth by any means, and you really have to give it some. Not like Makita's I've used in the past that glide along the rails.

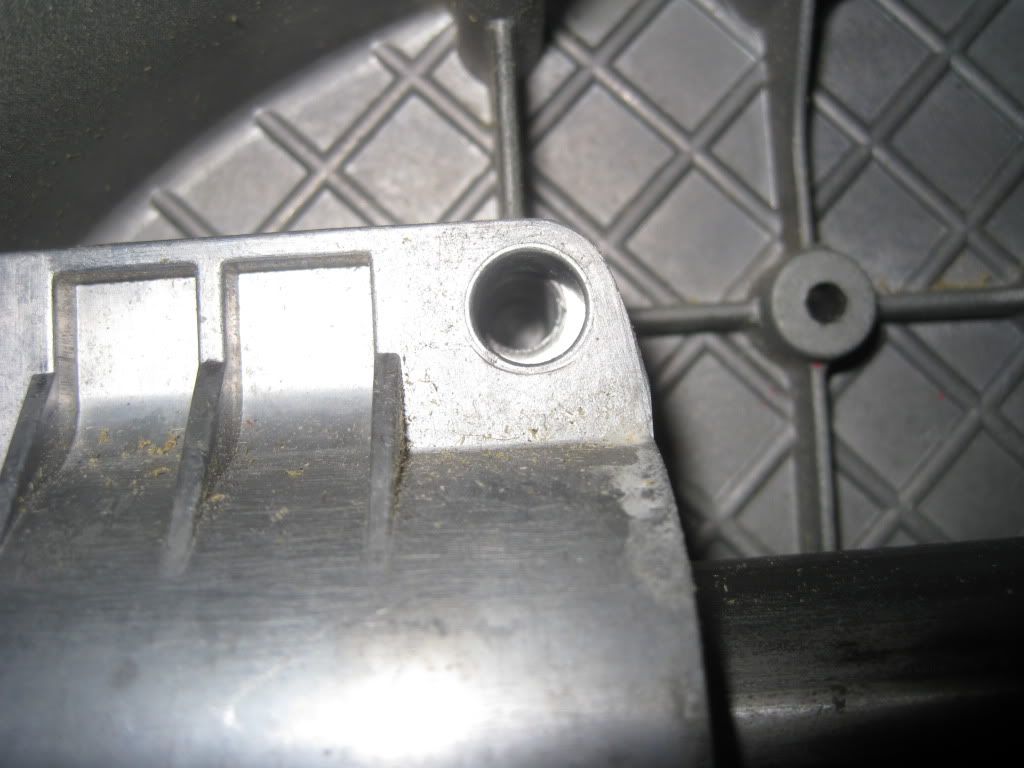

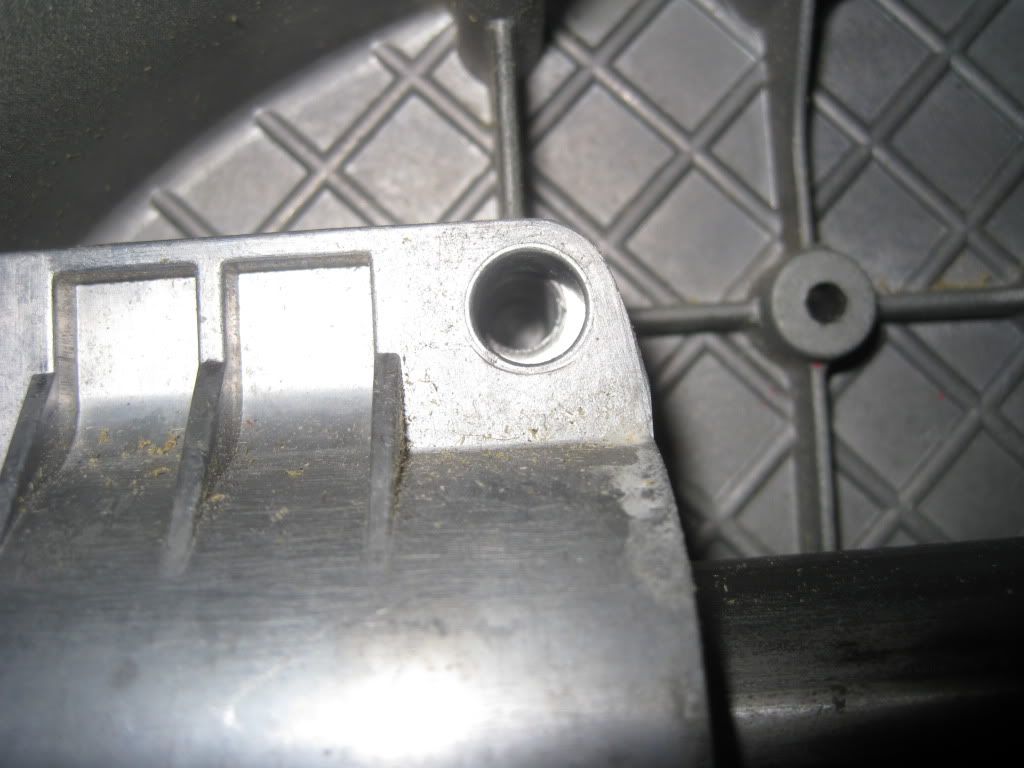

So, I took it apart slowly to get to the rails and grease them up to alleviate the poor action on them. Then I discovered a few things that didn't look right (see images below) The 2x allen bolts that anchor the slider housing/ sheath? (no idea what word to use here!) to the main body are not aligned correctly, furthermore the same kind of fitting on the winder that lets you change the angle of the cut are misaligned, so that when you use the knob on the front to change the angle, you can see the knob is rotating in a very haphazard way. After doing the relevant greasing I started to put it all back together again and when I'd finished I tried to move the angle of the cut round to see how it reacted, it was ridiculously stiff. The sliders work a lot better, but now the angle of the cut is very hard to change.

Also you can see that the main body looks like it has been misaligned from day 1 (pics 1 and 2), where the 2 parts of the body look like they are going to run into each other, but they miss buy 2-3mm or so.

Considering I've already left feedback for the seller (I didn't have space where it had been delivered to to fully test all the actions) what would you do? Has anyone got one of these to see if theirs is the same as mine in regards to alignment of things?

Failing all the above does anyone want to take it off my hands and fix it up and use it? I bought it for £370, so offers around this region will definitely be considered.

Thanks in advance, I really am in a pickle with this one Cheers_Dan.

Cheers_Dan.

I bought the aforementioned SCMS from Ebay, nearly a month ago. But I've only just now had a a chance to fully test it out.

I tried the motor as soon as I got it, it worked fine. But now after I've tried to slide the blade along the full length of it's travel I found it to be very difficult to do, it's not smooth by any means, and you really have to give it some. Not like Makita's I've used in the past that glide along the rails.

So, I took it apart slowly to get to the rails and grease them up to alleviate the poor action on them. Then I discovered a few things that didn't look right (see images below) The 2x allen bolts that anchor the slider housing/ sheath? (no idea what word to use here!) to the main body are not aligned correctly, furthermore the same kind of fitting on the winder that lets you change the angle of the cut are misaligned, so that when you use the knob on the front to change the angle, you can see the knob is rotating in a very haphazard way. After doing the relevant greasing I started to put it all back together again and when I'd finished I tried to move the angle of the cut round to see how it reacted, it was ridiculously stiff. The sliders work a lot better, but now the angle of the cut is very hard to change.

Also you can see that the main body looks like it has been misaligned from day 1 (pics 1 and 2), where the 2 parts of the body look like they are going to run into each other, but they miss buy 2-3mm or so.

Considering I've already left feedback for the seller (I didn't have space where it had been delivered to to fully test all the actions) what would you do? Has anyone got one of these to see if theirs is the same as mine in regards to alignment of things?

Failing all the above does anyone want to take it off my hands and fix it up and use it? I bought it for £370, so offers around this region will definitely be considered.

Thanks in advance, I really am in a pickle with this one