Part of the problem with the LNs and chipbreakers is that some of the planes need to have the chipbreakers replaced to work correctly. My 7 just ran out of adjustment as the chipbreaker was close enough to the edge to do anything, as opposed to being in the middle of adjustment as it should've been.

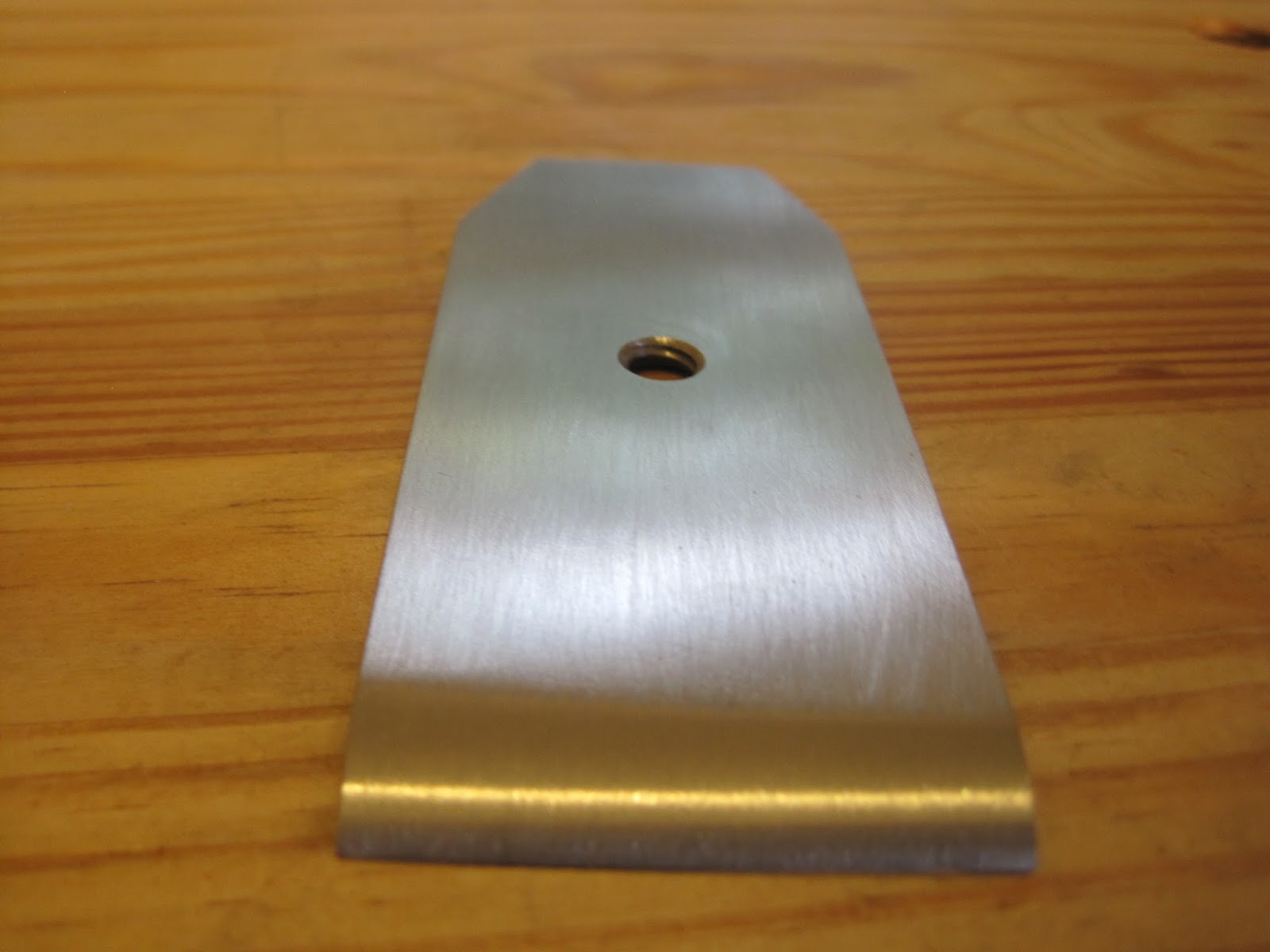

the thing that's missing from the modern chipbreakers is spring. I know there are people who prefer them, but the fit of the plane is abrupt without that spring, and there's a reason leonard bailey didn't design his cap iron like that and a reason all of the old woodies are the same way as baileys (they are just flat after the hump instead of half moon shape).

Certainly, the modern type cap iron setup will break chips, that's not rocket science. It's just not as good fitting in the overall design of the plane.

I'll disagree on the irons being for soft woods and hard woods only because I've switched only to vintage irons and used them on some pretty hard stuff (persimmon and cocobolo). I think most people will prefer the harder irons if all they are doing is smoothing very hard woods, though.

Long conversations about abrasion resistance usually indicate that someone is taking a shaving too thin to be productive. But that kind of stuff is the bread and butter of catalog ad copy.

I shipped a plane to brian holcombe. It has a relatively soft iron and I was very concerned about that. I know brian is a very skilled user, but sometimes people are looking for something specific and I was very put off by a couple of my irons in stock (dwight and french, and even some of the non-laminated but tapered irons from sheffield) until I used them. I'm sure they wouldn't last as long taking a 1 thousandth shaving, but at several thousandths, the gap closes considerably and you can use them right up to dull with absolutely no chipping. Brian, to his credit, picked up on that right away, all i did was suggest that if he was put off by how easily the plane iron can be sharpened that he should give it a couple of weeks of work first before deciding he doesn't like it.

Some of these things are why I make strange comments like "I think I might not have much advice to offer on forums at this point".

It's sort of in the same vein as the chisel edge holding. I found out quickly last year that a stanley chisel that may fail at 30 degrees in very hard wood will all of the sudden perform world champion quality work at 32, and that the difference between the premium expensive chisels and the cheap ones is a matter of a very few degrees.

Things I thought 5 years ago have been turned on their head.

the thing that's missing from the modern chipbreakers is spring. I know there are people who prefer them, but the fit of the plane is abrupt without that spring, and there's a reason leonard bailey didn't design his cap iron like that and a reason all of the old woodies are the same way as baileys (they are just flat after the hump instead of half moon shape).

Certainly, the modern type cap iron setup will break chips, that's not rocket science. It's just not as good fitting in the overall design of the plane.

I'll disagree on the irons being for soft woods and hard woods only because I've switched only to vintage irons and used them on some pretty hard stuff (persimmon and cocobolo). I think most people will prefer the harder irons if all they are doing is smoothing very hard woods, though.

Long conversations about abrasion resistance usually indicate that someone is taking a shaving too thin to be productive. But that kind of stuff is the bread and butter of catalog ad copy.

I shipped a plane to brian holcombe. It has a relatively soft iron and I was very concerned about that. I know brian is a very skilled user, but sometimes people are looking for something specific and I was very put off by a couple of my irons in stock (dwight and french, and even some of the non-laminated but tapered irons from sheffield) until I used them. I'm sure they wouldn't last as long taking a 1 thousandth shaving, but at several thousandths, the gap closes considerably and you can use them right up to dull with absolutely no chipping. Brian, to his credit, picked up on that right away, all i did was suggest that if he was put off by how easily the plane iron can be sharpened that he should give it a couple of weeks of work first before deciding he doesn't like it.

Some of these things are why I make strange comments like "I think I might not have much advice to offer on forums at this point".

It's sort of in the same vein as the chisel edge holding. I found out quickly last year that a stanley chisel that may fail at 30 degrees in very hard wood will all of the sudden perform world champion quality work at 32, and that the difference between the premium expensive chisels and the cheap ones is a matter of a very few degrees.

Things I thought 5 years ago have been turned on their head.