David, as I see it, there is a conflict of types of planes and the designs necessary for each. You are derogatory of the "Lie-Nielsen Improved" chipbreaker for the Bailey style plane, but often intermix your reasoning with wooden planes. Therein lies a problem - because it is well possible that the chipbreakers for woodies have different

additional effects.

Further, there is the assumption that Bailey did not mention the chipbreaker effect in his patent as this was already common knowledge and in common usage. That it was in common usage I am not disputing. That Bailey came up with his chipbreaker design as part of this process is something I will dispute.

Note that this is not a comment on the chipbreaker effect, but on Bailey's design.

Why is the Stanley chipbreaker/cap iron shaped as it is, and is the “Improved” LN chipbreaker really an improvement?

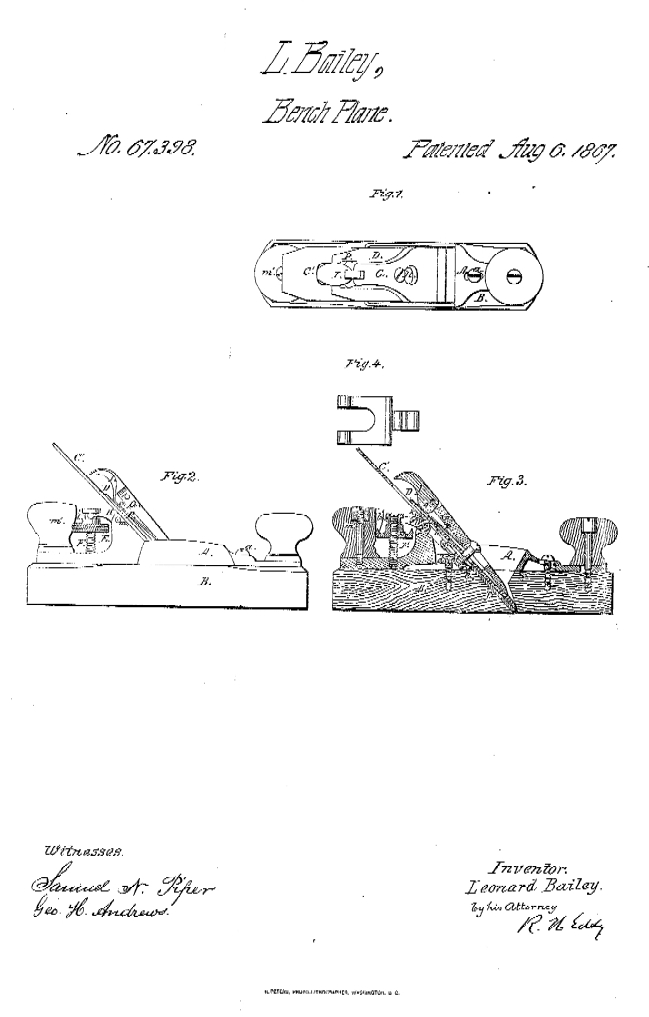

http://www.oldtooluser.com/Patents/plan ... _67398.htm

This patent of Bailey in 1867 was for the cap iron (as he referred to it). The patent specifies that the purpose of the cap iron is to connect the blade to the lever adjuster. It is relevant to note that the plane he was describing was a Transitional and not a full metal Stanley benchplane.

Whether or not it was already assumed that Bailey understood the “chipbreaker effect” – since this is not mentioned in the patent – it is only evident that the cap iron was designed for its mechanical properties.

One of the descriptions in this patent that appears to have been overlooked (or, I cannot recall any attention drawn to this point) is this: “As the lower surface of the part B may become worn away, from use of the plane, the opening of the lower part of the throat will- grow wider, and finally become so wide as to render it necessary to glue, or fix on the back 'or inclined face of that part of the throat which .is on the part B, a thin layer or plate of wood or other material of sufficient thickness to bring the plane-iron in its true relation with the front edge of the opening of the throat”.

What this indicates, in effect, is that Bailey considered that a closed up mouth was important for performance. The importance of a movable frog was to overcome the limitation of the mouth wearing. The significance of this statement is that he was NOT advocating the chipbreaker as a means of controlling tearout, but simply saw it as a mechanical connection to the adjuster.

Please note that I am not negating the use of the chipbreaker as a means of controlling tearout. I am a strong supporter that it works this way. This post is about chipbreaker design, per se. Specifically, “why” did Bailey come up with his design. Unless one can say this, how can one fully understand its current use.

There is a list of Bailey patents here, but none of them are about the shape of the cap iron, per se:

http://www.oldtooluser.com/Patents/wood ... atents.htm

Anyone with a modicum of engineering understanding will twig why the cap iron/chipbreaker is designed the way it is. The answer is simple because it is logical.

In a world where thin sheet steel is cheaper and profits are maximized when costs are kept down, the round front section is created to stiffen the thin gauge steel.

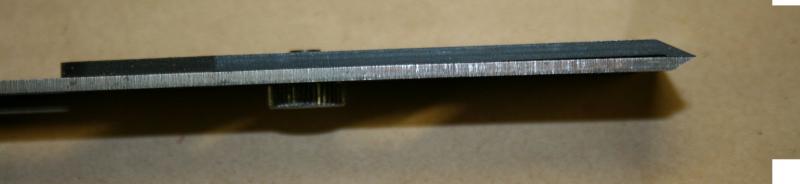

Any “spring” is a by-product of this. I do not believe that Bailey deliberately designed in the spring. However it was/is a happy coincidence since it enables the chipbreaker to remain under tension, which prevents it loosening and moving.

So what is it that LN/LV/new Stanley/et al have changed with the chipbreaker? Basically, all they have done is provide the solid section to the leading edge – a solid steel ledge – that Bailey would have done had he been less economical in his outlook ..

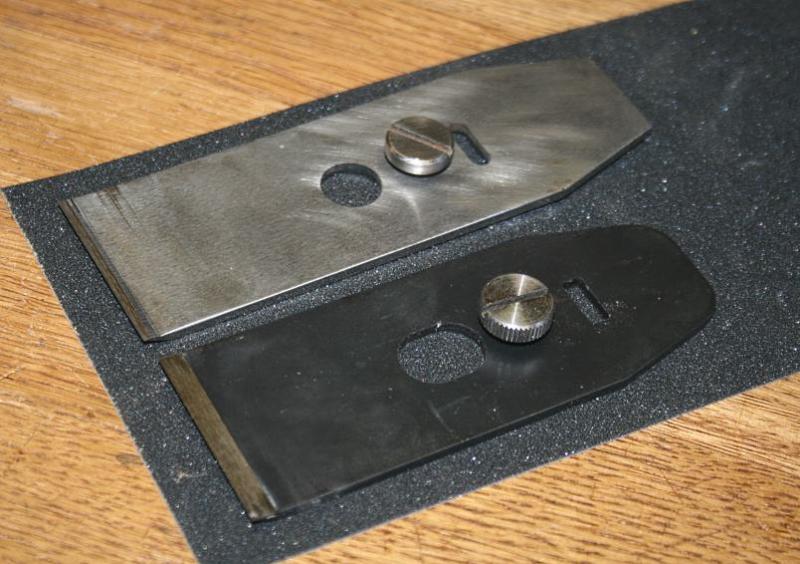

Underside of LN and LV chipbreaker ..

Flex/spring (under full tension) …

The question now is, how does this compare in performance to Bailey design in a metal Bailey-style plane?

Regards from Perth

Derek

p.s. I wrote this article some time back. I plan to re-write it with update on design factors and the experiences gained since that time. Still, there are some points that remain relevant (for metal Bailey planes):

http://www.inthewoodshop.com/ToolReview ... eaker.html