Mike.C

Established Member

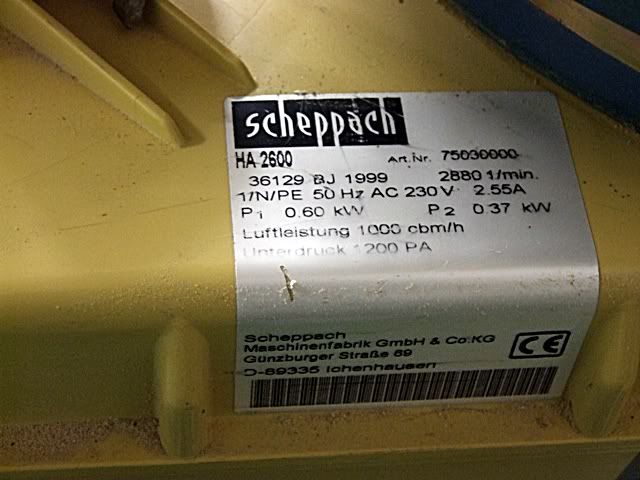

After turning on my 2 dust extractors (connected to a piped system) I switched on the P/T at which time the fuse blew. I put a new fuse in and turned it on again, and when it started I switched on the extractors. After planing a few boards I switched them off, went and got some more timber, but when I tried to start the planer it would not work, so I checked the fuse and after seeing it had failed I changed it again.

I turned it on again and then off and when I tried to start it would not work until I changed the fuse. So after changing it I finished thicknessing all the timber I needed, and on the off chance I switched it off and on again a number of times and it worked everytime ](*,)

I do not know what the hell is going on, but as part of it looked like it might be over heating I reached underneath and felt the induction motor which felt very very hot. I have no idea how hot these motors get but I could not hold my hand on it for long. ](*,)

I am hoping that it is not the motor, but unless it normally gets that hot I cannot see what else it could be. The strange thing is that except for the heat it is working normally now.

I would be grateful for any idea's?

Cheers

Mike

I turned it on again and then off and when I tried to start it would not work until I changed the fuse. So after changing it I finished thicknessing all the timber I needed, and on the off chance I switched it off and on again a number of times and it worked everytime ](*,)

I do not know what the hell is going on, but as part of it looked like it might be over heating I reached underneath and felt the induction motor which felt very very hot. I have no idea how hot these motors get but I could not hold my hand on it for long. ](*,)

I am hoping that it is not the motor, but unless it normally gets that hot I cannot see what else it could be. The strange thing is that except for the heat it is working normally now.

I would be grateful for any idea's?

Cheers

Mike