DBT85

Established Member

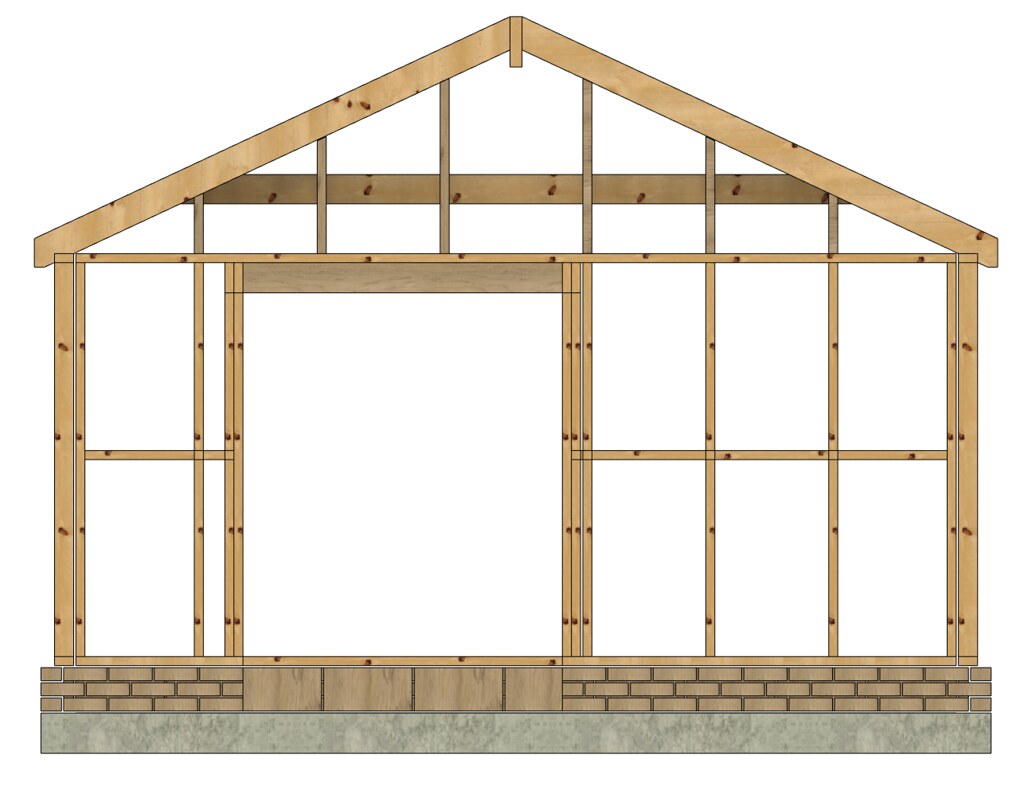

I saw studs filling the gable but not the expected large post right up under the ridge.MikeG.":3l3kq8tc said:A pair of 6x2s nailed together should be fine for the lintel, assuming the opening is of the order of 1500 or so. If you have that and studs up to the underside of the gable rafters (from the plate) then you're fine. That photo you show of mine is before any of that is in place, but later on in the build you'll see studs filling in the gable.

Door is around 1500 yes, I'll draw something up.

So 4x6 over the door onto the cripples and then normal studs all the way upto the rafters from the top plate /lintel.

Does one specifically have to go directly under the ridge?