The flip cart for the sanders is on its way though I've had to abandon hope for the integrated DX. I was getting ahead of myself.

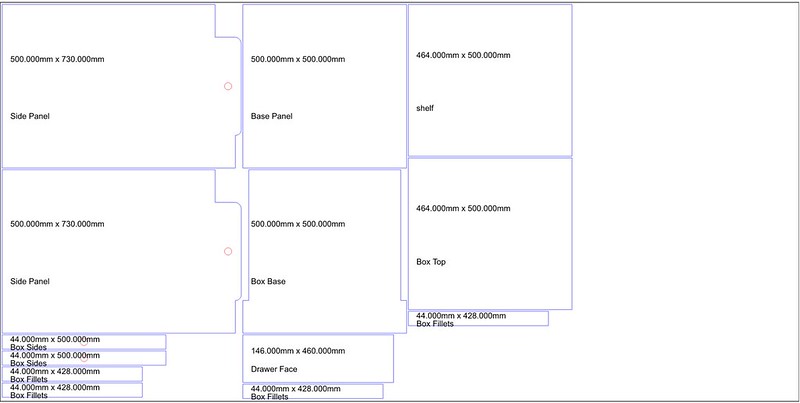

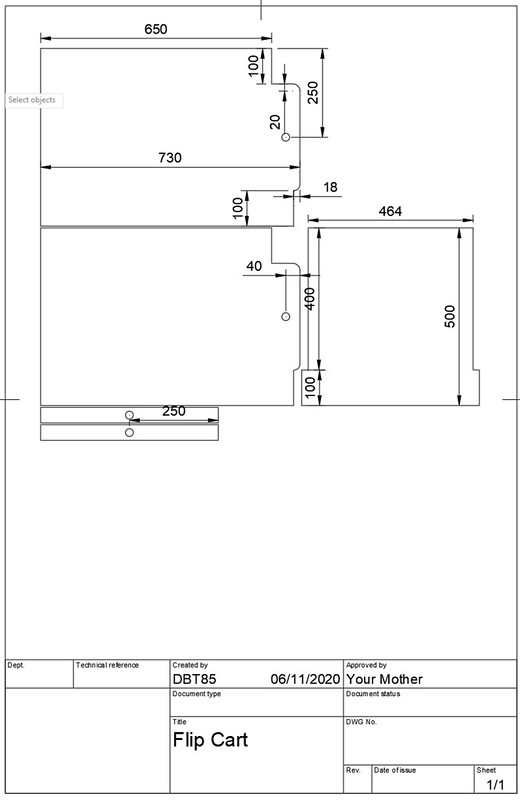

Plans drawn in Fusion, and then I used an extension called MapBoards to lay it out on a sheet of ply. I didn't entirely agree with where it placed things but it was my first time using it so maybe I did a dumb. I then used a Fusion Drawing to mark out dimensions for the twiddly bits. Both prunted it was time to head off t'shed.

The idea

The cutsheet (not putting all of the box fillets together was weird to me so ignored it for that)

Twiddly bits

Anyway, a little time on the MFT and my first real use of the TS55 and my first real project in my new workshop. It was largely heaven. Bright, spacious, everything not piled up on the area I was trying to work. Bliss. The only pain in the backside was the vacuum hose snagging and falling out of the dust port on the TS55. Something to be partly remedied when a new hose arrives and partly when I make a boom. Dust collection in general will be nice to finally sort out, but not just yet.

All the parts cut up and labelled, now on to the twiddly bits. My first screw-up came when using the tracksaw to cut the box base cutouts. I just went too far on one side, but not so far as to weaken it too much. Next up was cutting the notches in the sides, partly done with the tracksaw and then finished up with a wonky AF jigsaw. Next I needed to round 2 corners otherwise the flip top, won't. One could probably have been perched on the disk sander but the other wasn't going to work. Ah Ha, I remember what this hobby is all about now. So I made a little jig from a scrap of 6mm MDF with 4 different radius corners, double sided tape to hold it down and then used my little Bosch palm router. Done.

Now I needed a hole in each side panel to take the dowel and the same hole in the sides of the spinning platform. My random bit of curtain rail was ~28mm, I have a 29mm hole saw and a 30mm forstner bit, perfect. I'm also well aware that I struggle to drill straight. Given my uses, the 29mm hole saw was close enough so I cut a hole in anther bit of 6mm mdf and once again used it to route the holes required, first drilling out a 16mm hole with a spade bit to give my tiny pattern bit a little help and somewhere to descend into. Much less of a pain than trying to do it on my tiny bench drill, and much more accurate than me trying to do it with a hand drill.

Everything cut to size

The joy of a vice. No need to try and hold these edges together by hand to drill and screw.

The main unit assembled and wheeled

Flip base and disk/belt sander mounted

What the flip bed looks like

The bleary eyed among you may see a small issue. I didn't account for the belt part sticking out that far so like a tit I've mounted the unit it where it can't flip down unless I've lifted the belt up. I'll move that over tomorrow and finish up the last bit. Will be pleased to finally have these 2 off of my benches/floor and easily usable. But it works, it flips.