I headed out early doors with the sprog in tow to Kellaway to pick up the timbers I needed. Queued for the better part of 50 minutes only to pull in and be told "sorry we're all out till Monday...maybe".

With that and a BBQ afternoon all I got done was cutting down more timber for plates, lintels and whatever name is appropriate in your geography for the bits that hold lintels up :lol:

I did make one daft decision in that I ended up using 2 of my 2x6 boards for some lintels and had bits left over from each that would have served as another smaller lintel... which I'd already cut. So now I have 26 bits of 2x6 and 26 rafters to cut. Maybe I'll pick up a couple of spares just in case.

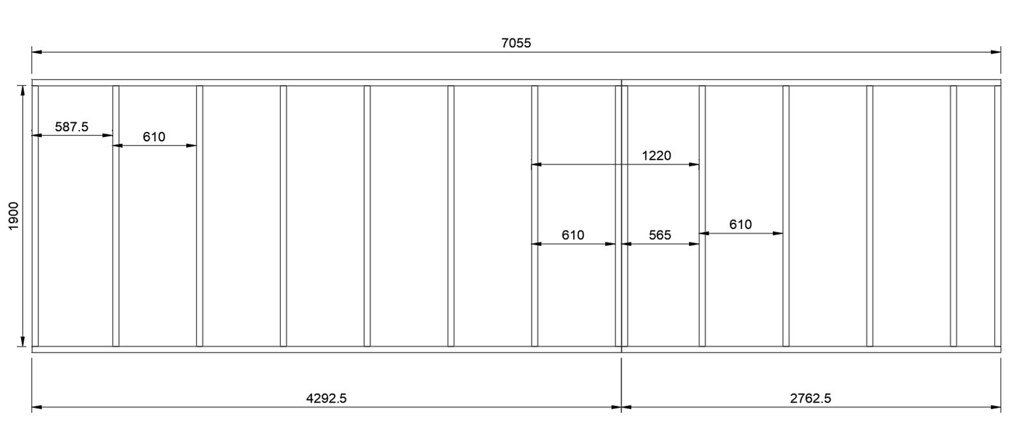

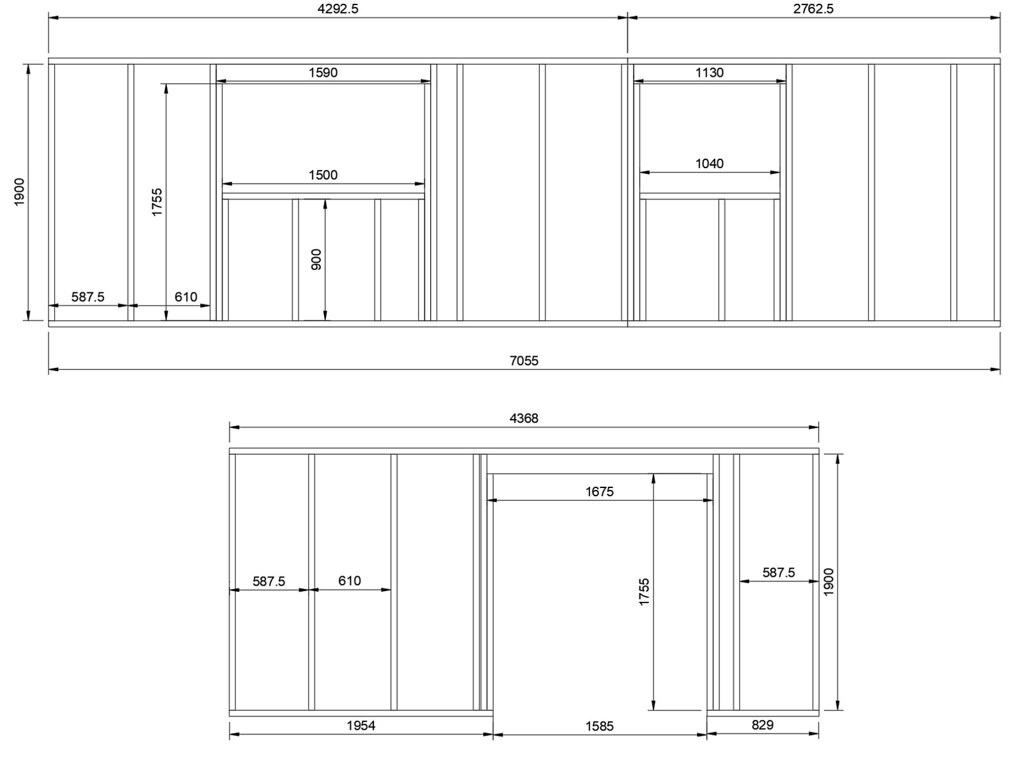

I also made one other mistake when planning my timber. My long 7055mm sides require two panels to complete. Once again I made my cut list before actually drawing the specifics (in my initial drawings its just one 7055mm long timber). That cut list was made along the lines of "I need 7.1m, I can get that from a 4.8m and less than half of 4.8m, so 3x 4.8m lengths will sort all my sole plates, and 3 more will do my top plates."

But when actually drawing it up the sections are 4292mm and 2763mm. The latter does not go into 4.8m twice!

You may ask why not just use 4.8m and then a section to finish? OSB comes in at 1220mm wide, 4x 1220 is 4880mm. So either I faff and have extra studs in places they aren't needed (I'd need one at the end of the 4.8m, and then another at the start of the next section, and then yet another to support the edge of the sheets), or I cut the first plate down to 3.5 sheets of OSB, and then the next plate will join on and the OSB sheet will overlap. BUT I hear you cry, 1220 multiplied by 3.5 does not equal 4292. Correct. But the first stud will be entirely covered in OSB, rather than only half covered, so that extra 22mm needs to be added on.

This probably makes no sense.

Here are the drawings of my frames. OSB will cover the entire face of each stud, which is why not all studs are on 610 centres.

Big question, do I measure for each stud location with a tape, or cut a couple of noggin sized bits and use those to mark out instead?

Also had a quick go with the Dewalt nailer. Sinks 90 ring shanks easily enough. Its a brute of a tool though. I'm going to look like hulk by next weekend. The 2 speed function just allows you to run in in a slightly lower power setting for nails under 70mm. I'm guessing less wear and tear and longer run time?