gasman

Established Member

Not really a traditional butler's table - but the client wants a side table with a removeable tray on top. There is going to be some fancy marquetry in the form of a college crest - plus inlays all round the sides as follows:

I am toying with putting a secret drawer in the back by drilling out one of the rear legs and replacing the inlay with a drawer with the inlay as the drawer front - not sure yet I need to think this through very carefully

This is a bit of a rip off of the Linley writing desks - but what the heck... so I mocked up a corner piece to see what it looks like as follows:

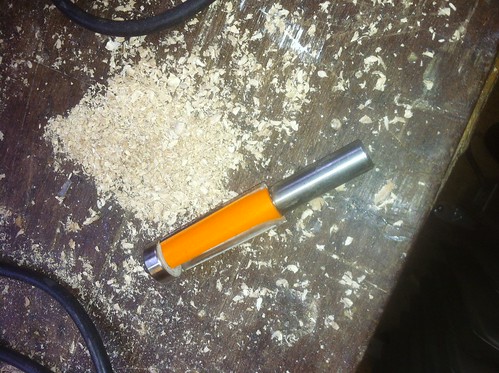

Also started on the legs and side pieces - from some nice quartersawn sycamore. The legs were made after shaping a template and double-side taping it to the 45x45mm leg blanks using a CMT bearing-guided spiral router cutter

[/url]

[/url]

I will do this as a WIP if people are interested

Best regards

Mark

I am toying with putting a secret drawer in the back by drilling out one of the rear legs and replacing the inlay with a drawer with the inlay as the drawer front - not sure yet I need to think this through very carefully

This is a bit of a rip off of the Linley writing desks - but what the heck... so I mocked up a corner piece to see what it looks like as follows:

Also started on the legs and side pieces - from some nice quartersawn sycamore. The legs were made after shaping a template and double-side taping it to the 45x45mm leg blanks using a CMT bearing-guided spiral router cutter

I will do this as a WIP if people are interested

Best regards

Mark