Benchwayze

Established Member

You're welcome Dibs...

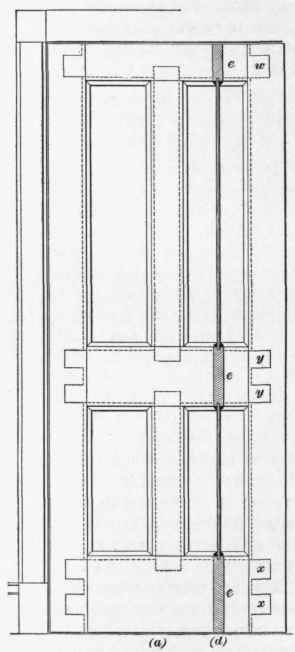

I'm sure the drawings and text will help, and together with the books you bought you shouldn't go far wrong.

Best of luck and enjoy the reading!

Regards

John

I'm sure the drawings and text will help, and together with the books you bought you shouldn't go far wrong.

Best of luck and enjoy the reading!

Regards

John