matthewwh

Established Member

I see the potential but also a risk. I once bought a block plane kit from a firm in the states and it was such a magnificently P155 poorly ground beach sand casting I had to calm down and dry my trews before taking it back to the post office.

If t'were done t'were better t'were done well, so I'll have a chat with our friends at QS and see what they can come up with. Any preferances as to reasonably well finished or really inexpensive but rough as a grumpy foundryman's language?

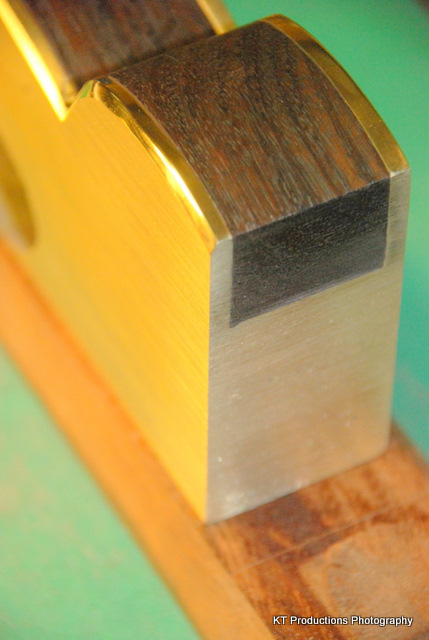

As far as the ears go, the ones I have seen are a straightforward stuff between the ears as you have them, finished to the same standard as the body but flushed straight across. Reason would suggest that this provided placement for the web of the thumb whilst trimming cheeks and fitted neatly between second and third finger while trimming shoulders. I've had a good rummage through google images but it's not the same since they stopped showing ebay photos.

If t'were done t'were better t'were done well, so I'll have a chat with our friends at QS and see what they can come up with. Any preferances as to reasonably well finished or really inexpensive but rough as a grumpy foundryman's language?

As far as the ears go, the ones I have seen are a straightforward stuff between the ears as you have them, finished to the same standard as the body but flushed straight across. Reason would suggest that this provided placement for the web of the thumb whilst trimming cheeks and fitted neatly between second and third finger while trimming shoulders. I've had a good rummage through google images but it's not the same since they stopped showing ebay photos.