ByronBlack":32qwpj6d said:

Jim,

I have a nice blank of zebrano if you want to go for something a litlte jazzy - great find though, I envy your bootsale-Fu.

Hi Byron....

That is really strange...when I was in Axminster today...there were some zebrano blanks and I had a look at them and mulled over the idea...but in the end, my love of rosewood got the better of me. I think it is the pleasure of working with the wood that does it..I simply love the smell..

I will see how this comes out with the rosewood and may take you up on that if it doesn't work out...thanks mate..that's very kind of you to offer.

Here is the blank that I bought:

I wanted a big enough bit so that I can match grain without having to get another piece if I under estimate for the whole infill...

First...I cut a closer blank out and squared and smoothed the sides using my trusty No.7....I really love that little plane!

Indian rosewood tends to tear out more than Brazilian so the sharp iron was essential...at LAST...tests for my faffing around with scary...and grinding jigs and other "theoretical" edge refinements over the last week...

There was virtually no tearing at all, just nice curly shavings...

Then over to the bandsaw..(what would I do without that baby)...to cut out the rough shape....remembering to ALWAYS cut very shy of the line...

The inside of this infill is really convoluted...in fact...it's a blinkin' nightmare! My little Aled kit shoulder plane came in handy here to create the ridge inside...and it performed perfectly!

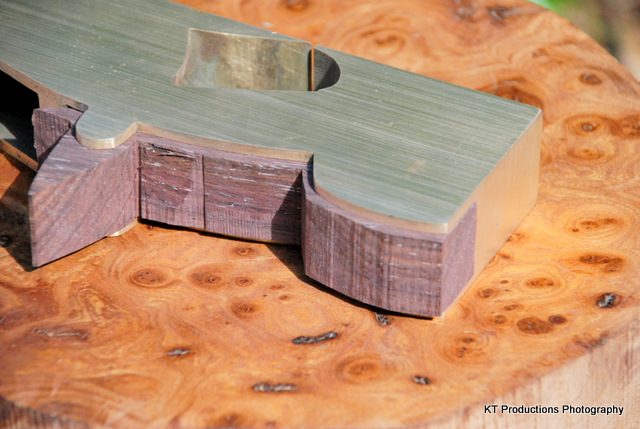

The inside front of the infill hooks forward as you can see...this creates a very positive lever alignment to pull the whole infill down inside the cavity...very clever....but a nightmare to get just right...my Japanese chisel simply whizzed through the remaining trim:

Now for a test fit...

A bit of filing needed there on the brass to line the bottom edge up but the leverage worked perfectly....just a small tap with a leather mallet and it fits perfectly...

....actually...it was too darn perfect....I had a hell of a job getting it out again!

As you can see, enough waste to spend some time trimming it down flush and enough of a lump at the top to put a horn in...if I fancy...

Now....to fiddle with the 01 a bit...I really MUST get a metal cutting blade and one of those small table saws...

Later...

Jim