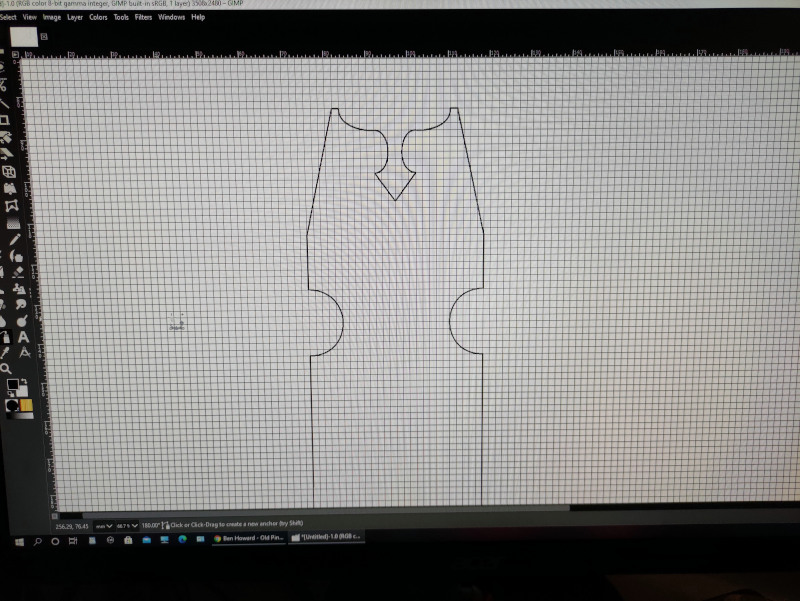

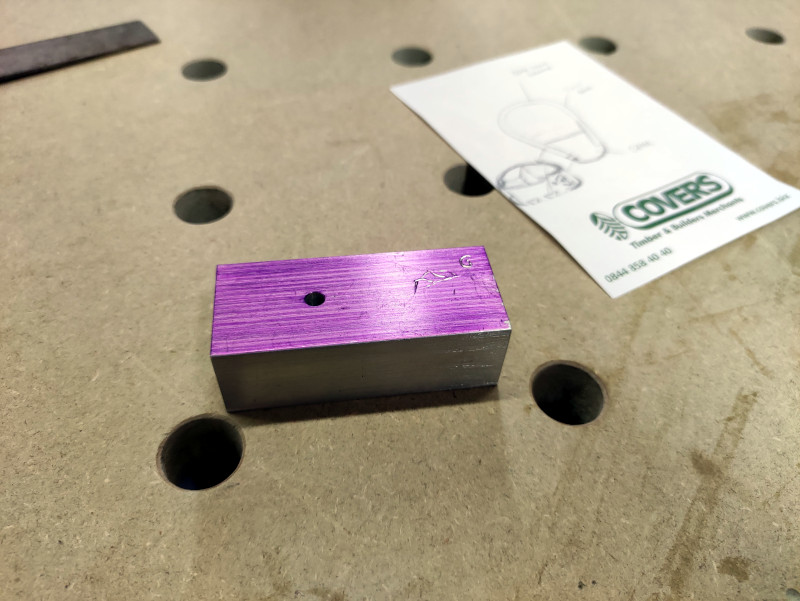

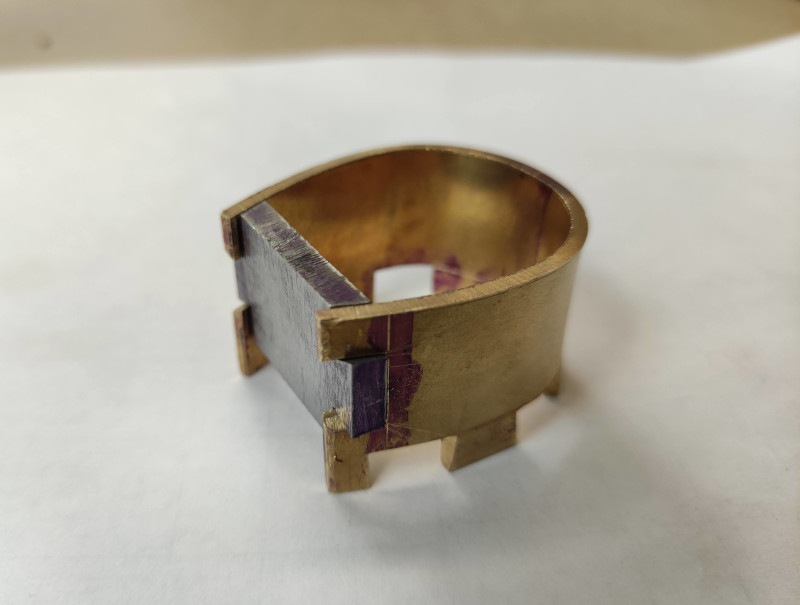

With the plane body now formed I started to make the back brace.

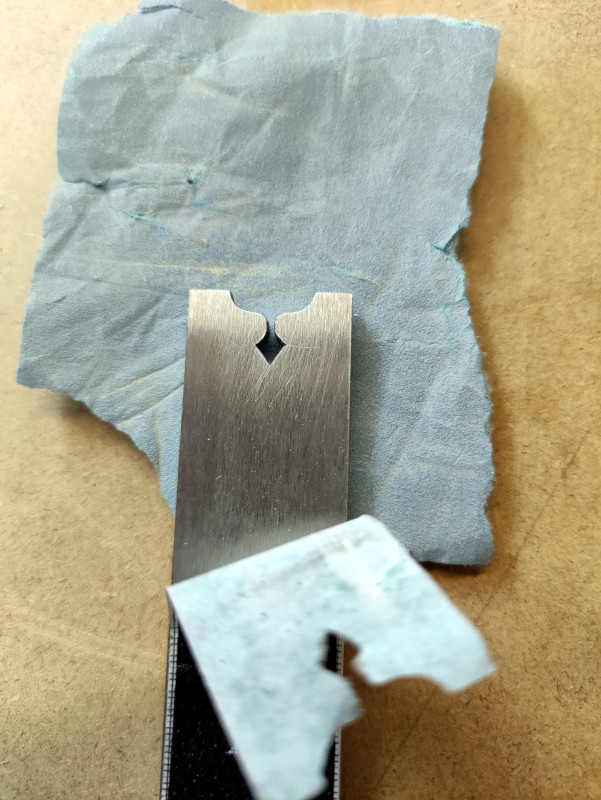

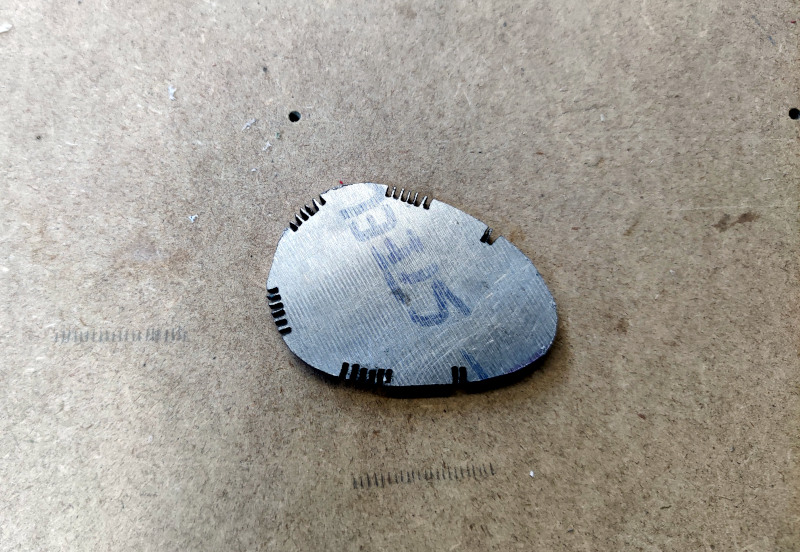

I cut a piece of 01 tool steel and started to form the dovetails to match the body.

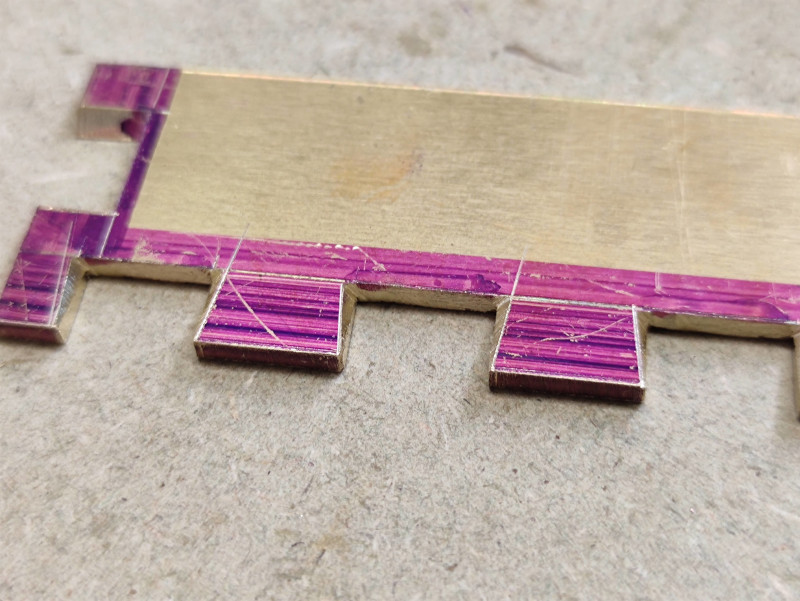

This turned out to be a little more difficult than I had expected as the shoulders of the dovetails had to be curved to follow the curve of the plane body, along with the back face slightly tapered.

After a lot of careful filing they started to fit. This process was made even more tricky due to the spring back from the body.

I was expecting a small amount of spring back from the body and this was the reason why I cut these dovetails at a steeper angle.

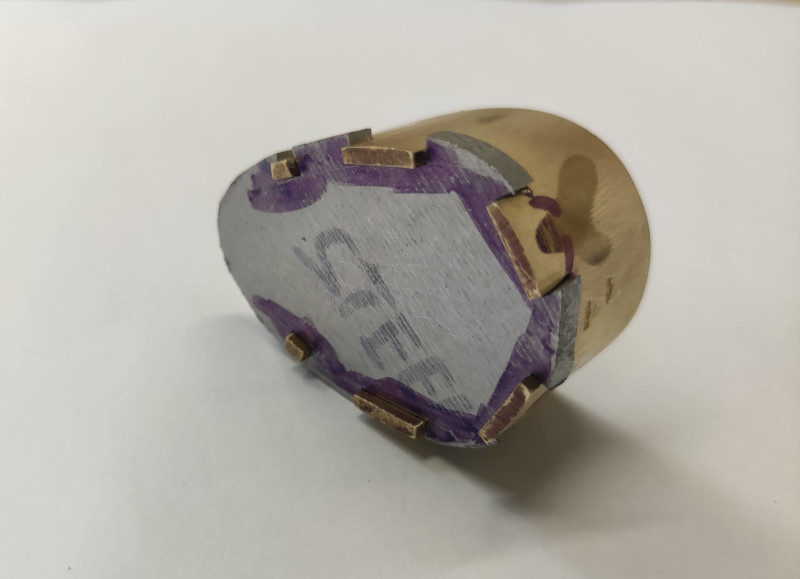

I hoped that the pressure from peening would help to force the shoulders tight at the top and bottom of the plane body.

I feared had I cut these any shallower the spring back from the body would have caused gaps between the brace and body on the shoulders.

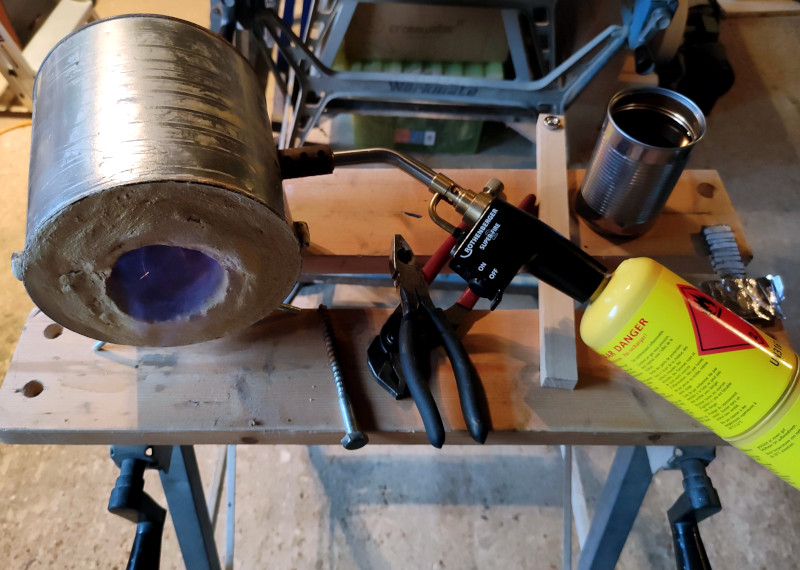

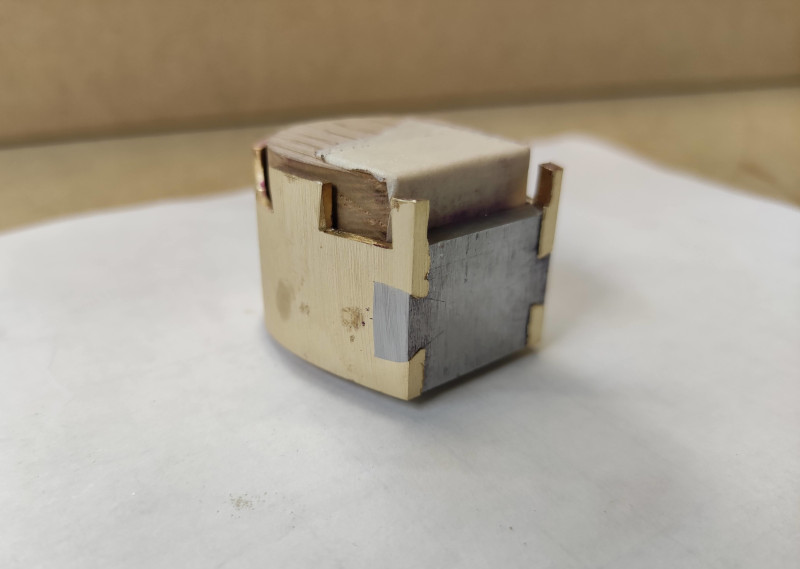

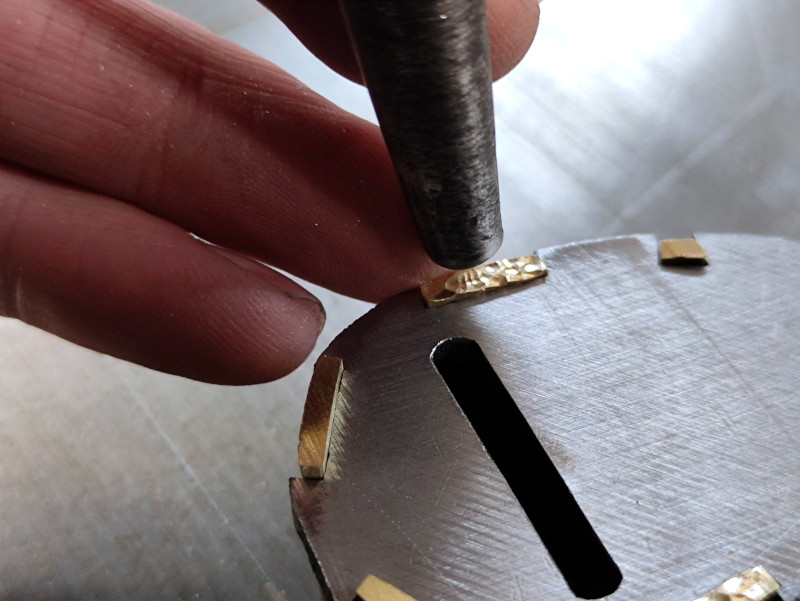

Next came the first stages of peening and the first doubts that this project may fail.

One thing I've learnt along the way is that accurate peening is difficult, and in some situations it's better to use a rounded punch with light blows from a heavy hammer than wild swings from a lighter one.

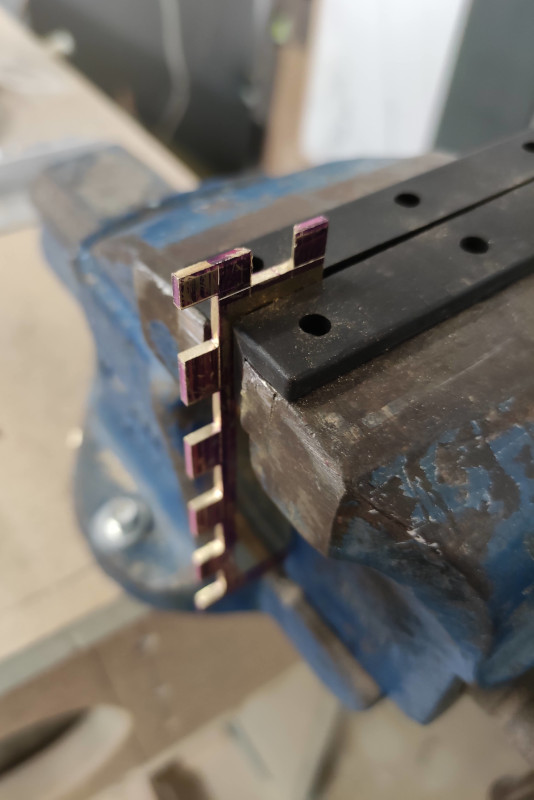

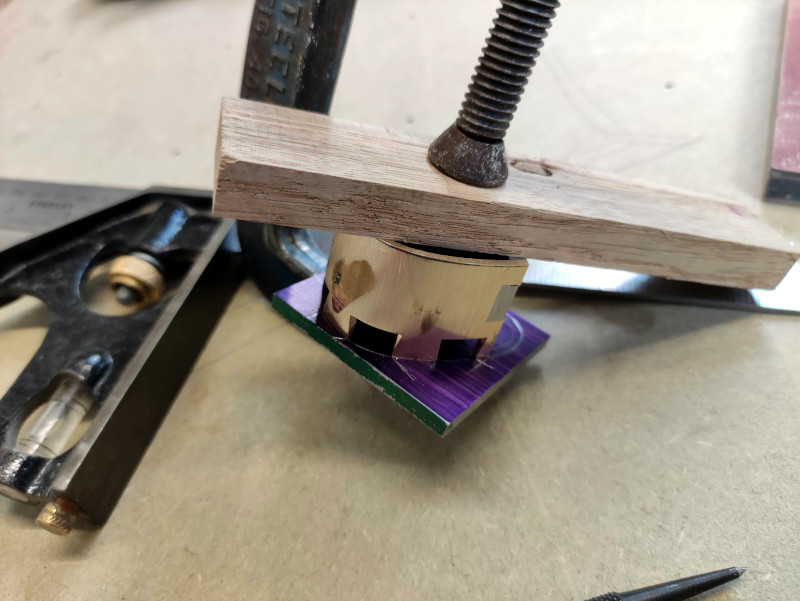

It's also crucially important to hold the work piece rigid and have the opposite point of impact most supported, this is difficult to do when the piece being worked is curved.

I tried several ways of holding the body without distorting it so I could use my rounded punch but as soon as the first strike came the body would either slip loose or distort.

In the end I resorted to wedging the body against a steel upright and using light blows direct from the hammer. Wedging the body against something stopped it from slipping away and the impact point was directly underneath where I was peening.

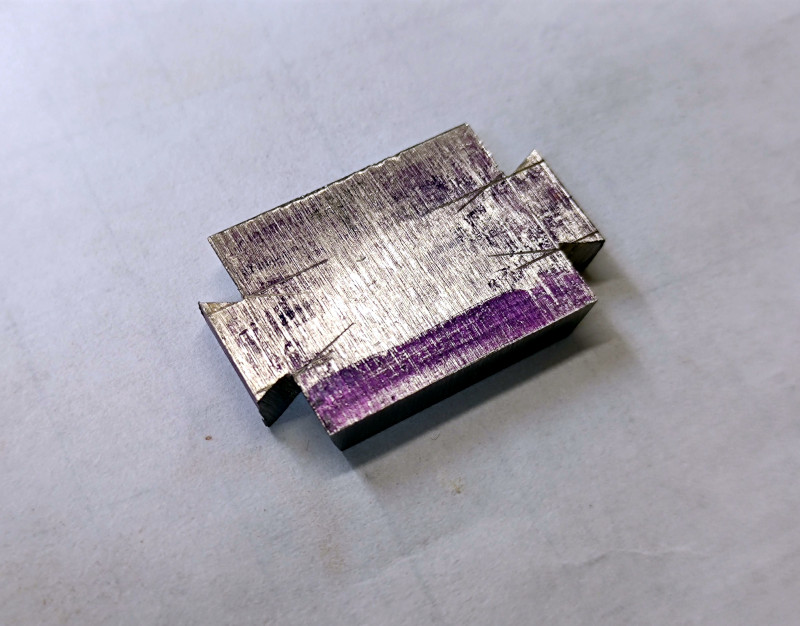

finally after a lot of apprehension the peening was done, It was easily one of the most difficult things I've peened so far. Holding the plane still with one hand coupled with it's small size meant I was peening blind, It took a lot of careful well placed blows with the constant fear in the back of my mind that if I miss hit there was a very likely chance I would snap off one of the brass dovetails, or at least irreversibly bend it out of shape.

Thankfully after a lot of sweating the peening was done.

The steep dovetails had worked and the brass was forced up tight to the braces shoulders...what a relief

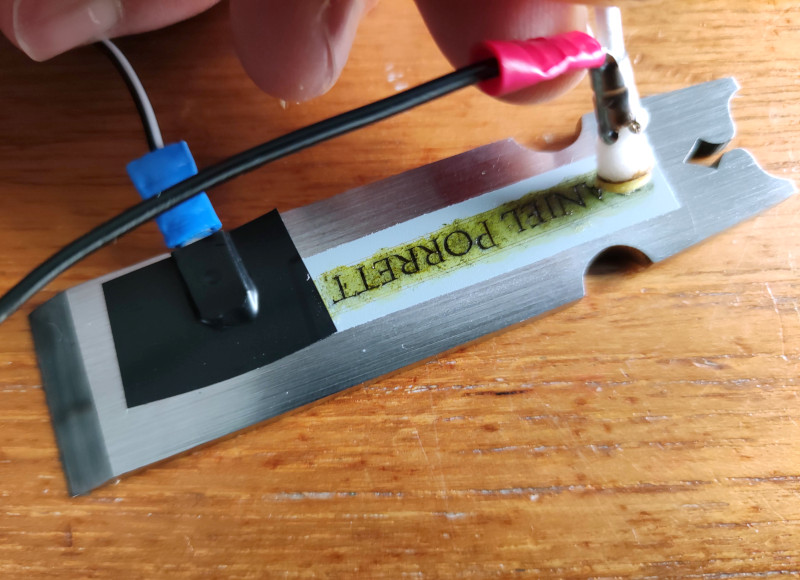

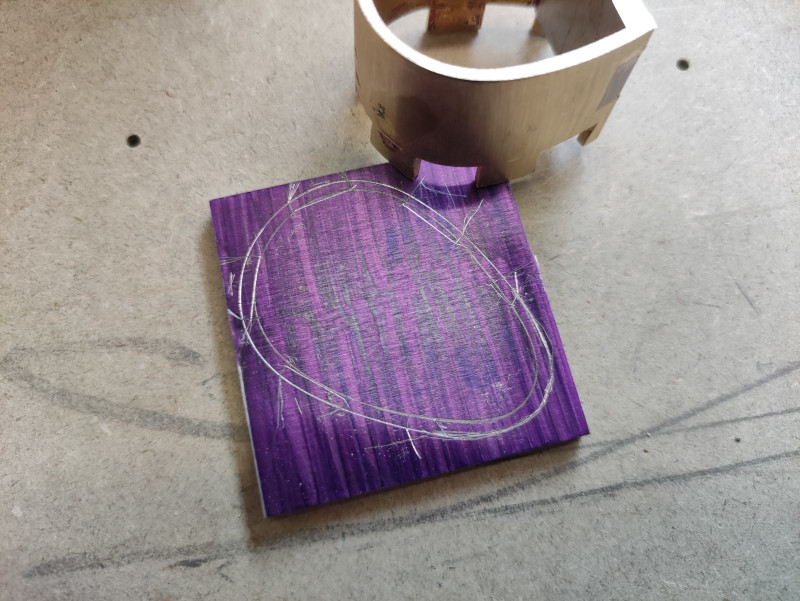

With the body permanently fixed in position I could start work on the sole.

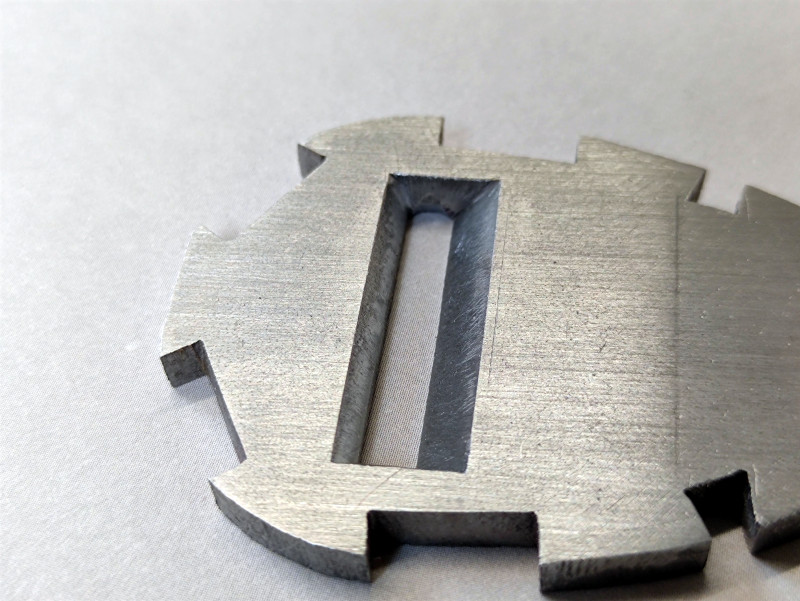

I cut a piece of 01 tool steel and clamped the body to it so I could accurately scribe around the dovetails.

Marking the waste I cut away the surplus metal and shaped the sole to allow enough for peening later.

I cut a series of notches as before and tapped out the waste with a punch.

Then filed down to my scribe lines

Again after a lot of test fits and careful filing the sole was fitted.

.....