Hi,

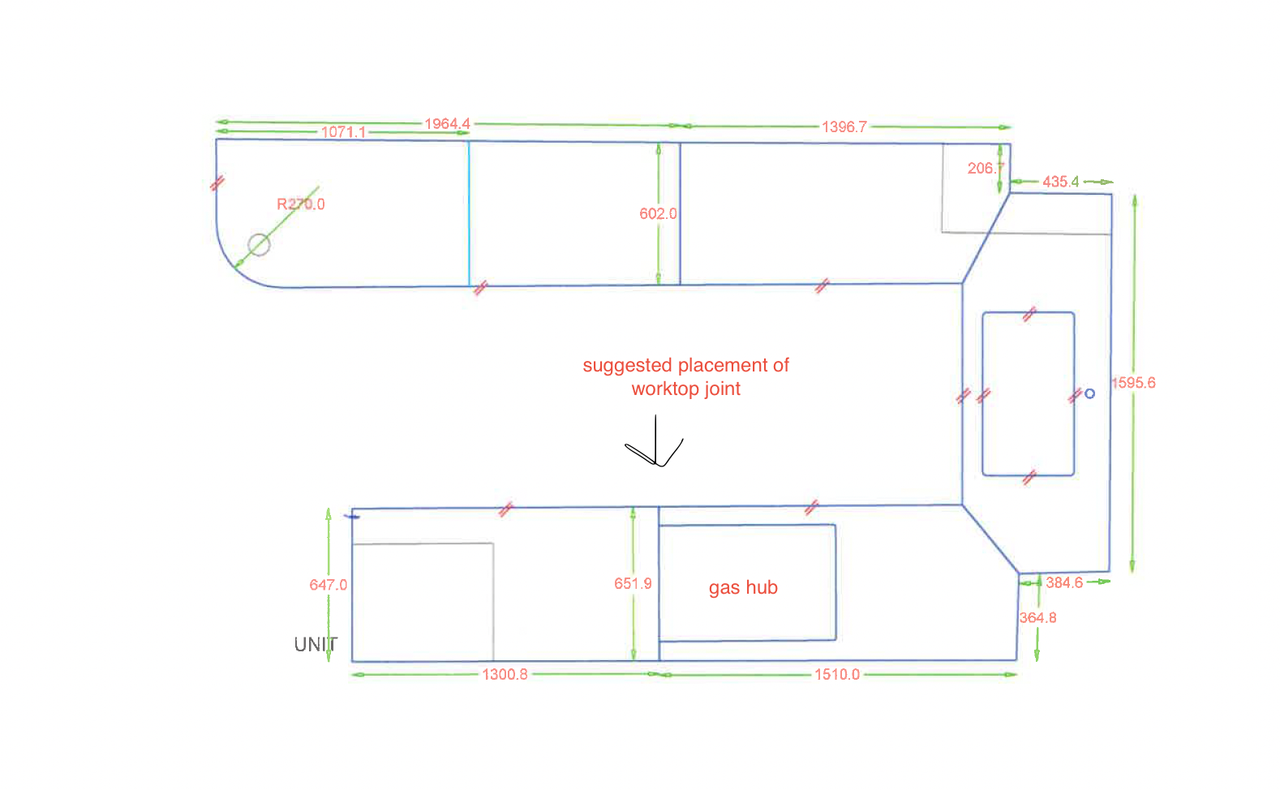

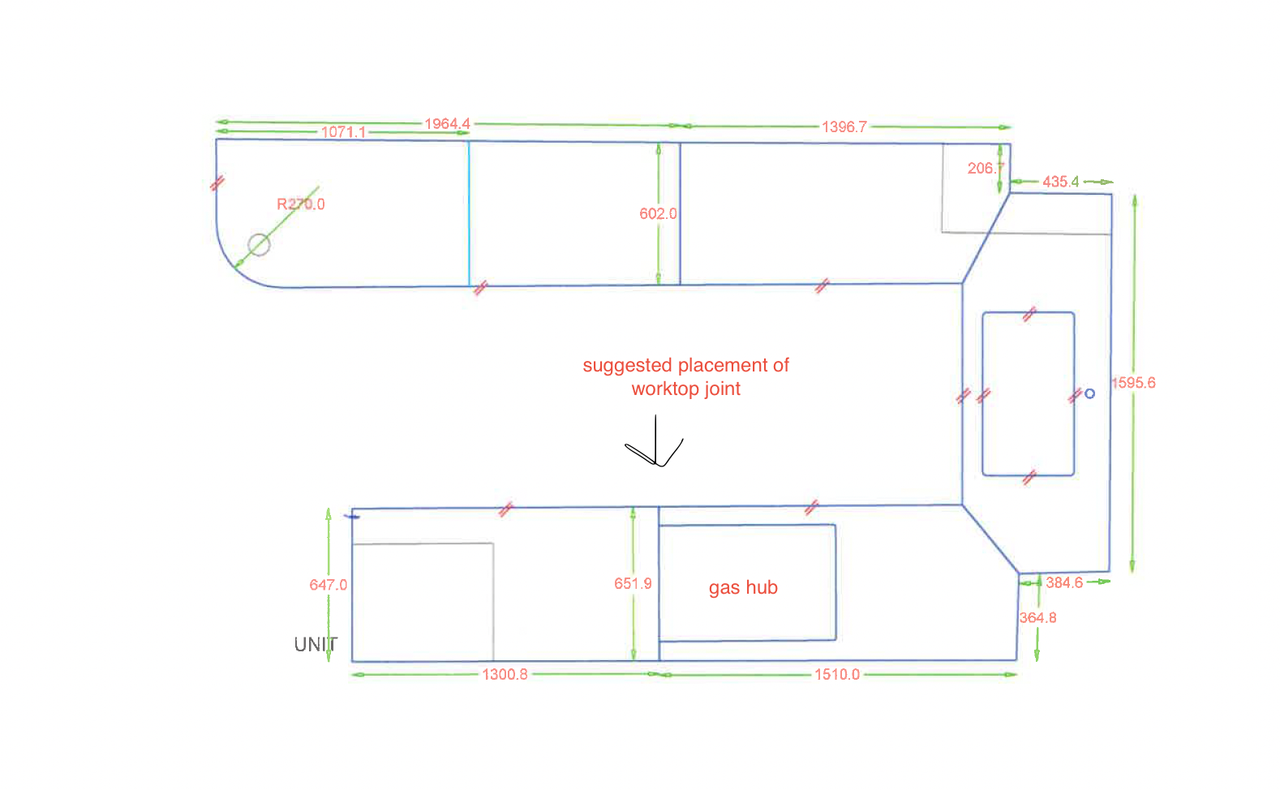

We are having a quartz worktop fitted in our kitchen. The kitchen company and their fitters are suggesting to put a joint exactly next to the hub. I protested that it might not be a good idea given heat and stress etc (per my internet search) but they insist this is the best place.

Could someone please advise on what is best practice? much appreciated!!!

We are having a quartz worktop fitted in our kitchen. The kitchen company and their fitters are suggesting to put a joint exactly next to the hub. I protested that it might not be a good idea given heat and stress etc (per my internet search) but they insist this is the best place.

Could someone please advise on what is best practice? much appreciated!!!