KT_NorCal

Established Member

Hi All,

I'm from over in the States and this is my first post here although I've been reading through some old threads plus using the search function for several weeks trying to gather as much background info as possible on an AGS10 I recently purchased as well as a WB BER2 I picked up several months ago.

The AGS I just picked up is a 79 that was purchased new out here in California. I'm the second owner which I think is cool. The previous owner was a private business that made lighting fixtures from California Redwood and this was just one of several Wadkin Bursgreen saws they had bought. One of the other ones is a crazy scary looking gang-rip saw (or "multi-rip" BSW I think it was called) with seven or eight very large blades on it... and a 40HP electric motor... this AGS was at the other end of the scale!

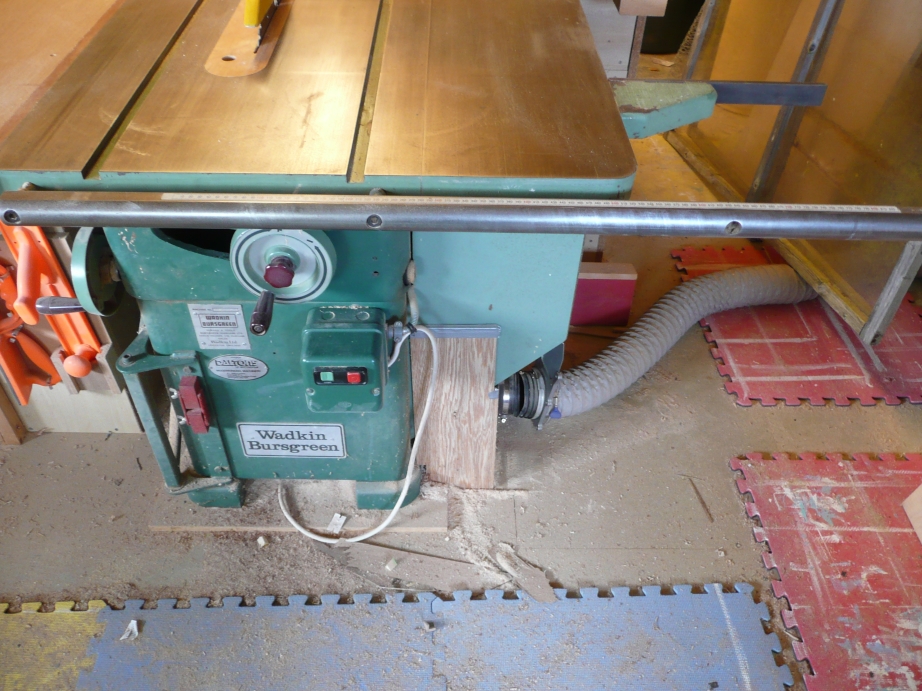

I have been on the lookout for a BGS 10 or maybe 12 for a while, but suspect they were never imported to the States and had basically given up hope of finding one when this popped up, so I grabbed it as a consolation prize. It seems to be a fantastic saw. Went and picked it up the same day the fires started here in Northern California with all the extreme winds, so towing it back home was an interesting experience. It is relatively complete with only a few bits missing.. one of which is the dust extraction hood which the PO thinks he might have been guilty of tossing as they closed the business given its rather strange non-dust hood shape. It has sat for many years essentially unused, so will need to be taken apart cleaned and put back together again. Did some light cleaning of the top as it was covered in a thin coat of "barn rust" from sitting around for so long, but that is it so far.

Only thing that definitely is wrong (as far as I can tell) is that the 10" blades don't fully retract as it is currently, but I think I see two set/limit screws on the trunnion that might be the guilty parties. Also there is an extreme amount of lash on the raise/lower gear/handle, so will need to figure that out too. The arbor nut also has gone on a walk-about, which is a bummer, since I'm rather sure the arbor is a 5/8" BSW left hand thread... which means I will definitely not be picking one up somewhere locally. The upside is that I apparently have the rather rare dado arbor nut, because that is what seems to be clamping in the blade that was on the saw.

Biggest bummer is that I had thought all WBs after an early 70s date came with riving knives... turns out at least the US market ones all came with a "US spec" blade guard that made riving knives unusable (fantastic safety logic, that), so this one has what is really a splitter... which bums me out significantly. I'm hoping some members here who have one of these can tell if it is something that can be retrofitted as it looks like the trunnion has all the appropriate holes to use a riving knife, it just doesn't have one.

First couple of surprising observations after spending only an hour or two with it... It was almost comically heavy for a 10" table saw... I have a Unisaw and I swear it feels close to double the weight. If I hadn't brought a drop-deck trailer the move probably wouldn't have happened that day. Secondly, the fence seems to be really, really nice. Doesn't seem that sophisticated, but is rock steady and extremely easy to use (even with rusty internals and guide bar (which turned out to be solid steel and almost dropped on my leg.. see previous comment on it being a silly heavy saw).

I attached a few pics below and then will post some of the questions I come up with as I go along. The main one will be regarding possibly retrofitting a riving knife, but also would be interested in seeting any pictures members here have of the "exaust hood" (part D-1026/355) as I will defintiely try and fab one up soon.

Thank you!

I'm from over in the States and this is my first post here although I've been reading through some old threads plus using the search function for several weeks trying to gather as much background info as possible on an AGS10 I recently purchased as well as a WB BER2 I picked up several months ago.

The AGS I just picked up is a 79 that was purchased new out here in California. I'm the second owner which I think is cool. The previous owner was a private business that made lighting fixtures from California Redwood and this was just one of several Wadkin Bursgreen saws they had bought. One of the other ones is a crazy scary looking gang-rip saw (or "multi-rip" BSW I think it was called) with seven or eight very large blades on it... and a 40HP electric motor... this AGS was at the other end of the scale!

I have been on the lookout for a BGS 10 or maybe 12 for a while, but suspect they were never imported to the States and had basically given up hope of finding one when this popped up, so I grabbed it as a consolation prize. It seems to be a fantastic saw. Went and picked it up the same day the fires started here in Northern California with all the extreme winds, so towing it back home was an interesting experience. It is relatively complete with only a few bits missing.. one of which is the dust extraction hood which the PO thinks he might have been guilty of tossing as they closed the business given its rather strange non-dust hood shape. It has sat for many years essentially unused, so will need to be taken apart cleaned and put back together again. Did some light cleaning of the top as it was covered in a thin coat of "barn rust" from sitting around for so long, but that is it so far.

Only thing that definitely is wrong (as far as I can tell) is that the 10" blades don't fully retract as it is currently, but I think I see two set/limit screws on the trunnion that might be the guilty parties. Also there is an extreme amount of lash on the raise/lower gear/handle, so will need to figure that out too. The arbor nut also has gone on a walk-about, which is a bummer, since I'm rather sure the arbor is a 5/8" BSW left hand thread... which means I will definitely not be picking one up somewhere locally. The upside is that I apparently have the rather rare dado arbor nut, because that is what seems to be clamping in the blade that was on the saw.

Biggest bummer is that I had thought all WBs after an early 70s date came with riving knives... turns out at least the US market ones all came with a "US spec" blade guard that made riving knives unusable (fantastic safety logic, that), so this one has what is really a splitter... which bums me out significantly. I'm hoping some members here who have one of these can tell if it is something that can be retrofitted as it looks like the trunnion has all the appropriate holes to use a riving knife, it just doesn't have one.

First couple of surprising observations after spending only an hour or two with it... It was almost comically heavy for a 10" table saw... I have a Unisaw and I swear it feels close to double the weight. If I hadn't brought a drop-deck trailer the move probably wouldn't have happened that day. Secondly, the fence seems to be really, really nice. Doesn't seem that sophisticated, but is rock steady and extremely easy to use (even with rusty internals and guide bar (which turned out to be solid steel and almost dropped on my leg.. see previous comment on it being a silly heavy saw).

I attached a few pics below and then will post some of the questions I come up with as I go along. The main one will be regarding possibly retrofitting a riving knife, but also would be interested in seeting any pictures members here have of the "exaust hood" (part D-1026/355) as I will defintiely try and fab one up soon.

Thank you!