I think I am coming to agree with you but until I try some other bits I will hold judgement - the long straight bit I bought for trimming my decking boards to the joists worked very well...Chems":gugojikm said:I have come to realise that trend are awful.

Where you trying to do it in one pass? Where you getting a lot of burning?

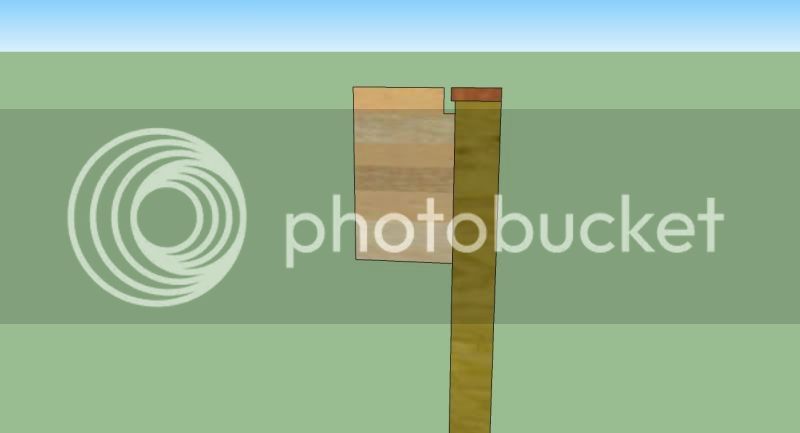

I am taking a full depth cut but only a few mm at a time horizontally. No burning but some break out - I suspect I need to think rather more about the direction of travel for each of the cuts

Miles