Unless you're doing constructional work, torque isn't of itself the important thing.

The tricky bit is getting the torque from whatever is driving it (hand/arm or motor) to the pointy part, where the thread is being made through the wood fibres. The interface between screw and driver is critical to this - if the driver can't engage properly, or deforms the screw head or shaft, that's wasted energy. I'm sure we've all put a fresh battery in a powered screwdriver ready to go, and the first screw we try... whoops! Chewed head and it's start again time!

I prefer my long-handled screwdrivers, so much so that, when I lost one for electrical work, I spent over a year looking for a good replacement. Then I found it again, after I'd bought two to replace it!

They are better, especially with slotted screws, because they encourage you to work better. It's all down to angles: Some screw head designs will cope with a screwdriver used off-axis, such as Robertson, Torx and Pozidriv (to a slight extent). Others can be abused a bit but it does damage, such as Allen (hexagon) heads.

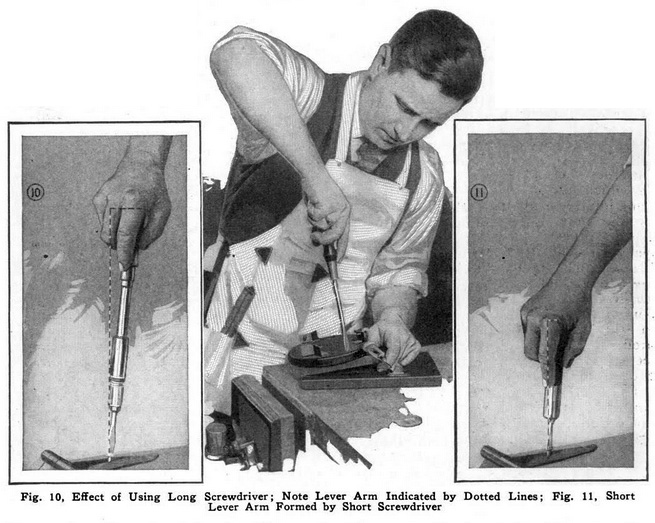

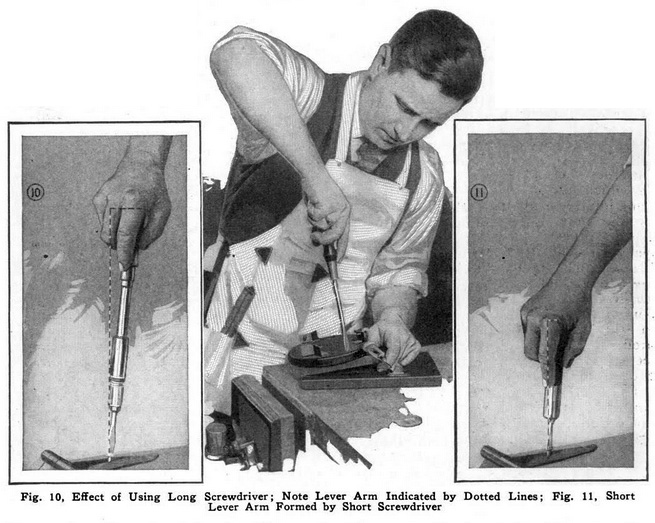

Most screws - straight slotted and Phillips being the most important for us - are designed to work with the driver dead-on on the axis of the screw, and performance drops off rapidly when it isn't.

This is the main reason why you get on better with a big screwdriver - you can see the angle of attack clearly, and any wobble distance at the handle has far less effect at the screwhead than it might with a stubby screwdriver. You can also grip the handle better, as your hand isn't obstructed by the thing you're working on, or your other hand holding the screw, or whatever. And it is probably true, too, that you can position your elbow to get better driving torque - with a shorter driver you often haven't got room off he work's surface to get hand and arm into the ideal position.

As I get older, my grip gets worse. Years ago, I always used to carry a stubby Phililps screwdriver around with me in my briefcase(!), for getting into equipment (when there wasn't time to call maintenance, boss!). Now I hate using the things.

Oddly, it's the same with power tools: I have a much better time using extended length driver bits in the screwdriver. I own a right-angled drill/driver too, and it's one of the most awkward things to use, mainly because it is so difficult to keep it straight on the screw head.

An aside: you're trying to get the power you produce through the head of the screw, to the pointy part, as efficiently as possible. I find diamond coated bits work really well for this, as they grip and don't cam out like ordinary bits do. It improves battery life, the bits last a lot longer, and they do a lot less damage to screwheads. They're so good, that I often use them hand-powered in a ratcheting handle, instead of with the powered driver.

So that's my three-and-fourpence-halfpenny...

E.