I have one of those Tony, and have also had lots of problems getting it to work properly. In fact I put mine back in the box and pretty much ignored it for almost a year until I had another bash with it a few weeks ago. I got it sorted out recently and have been meaning to write up the saga here for a while now, hadn't got round to it until your post prompted me.

I had always assumed it was me being thick and not using it correctly, but on the advice of Mathew of Workshop Heaven I e-mailed Rob Lee about my troubles. I have to say I have nothing but the highest praise for Rob and his colleague Steve Oszmian for their swift action. I got a reply from Rob within hours, despite having caught him on holiday, and he put Steve onto the problem.

It turns out that the design of LV's LA block plane was modified slightly to make it stronger and this involved making the toe a little thicker, and consequently the pocket for the adjustable part a little deeper. This means that when the chamfer guide (dimensioned to fit the shallower pocket) is substituted, the toe is now substatially lower than the rest of the sole.

This resulted in very heavy cuts when chamfering and therefore very poor results with lots of tearout, it really was unusable.

Steve's solution was to send me some shims to try out under the chamfer guide to rectify the difference. He sent me 20, 10 and 5 thou shims, and I found that .025" was just about perfect. I now have a chamfer guide that works perfectly.

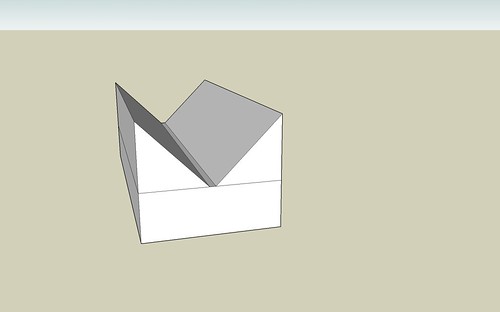

I don't know whether your's suffers from the same problem Tony, I've no idea how many chamfer guides were made to the earlier dimensions and then wound up being paired with later planes, but it's worth checking. The easiest way is to remove the moveable part of the guide, then attach it to the plane and check with a straight edge (although as you can see from the first pic the problem's pretty easy to see without any dismantling). If you see a gap like this you'll need to get in touch with LV for some shims (or whatever other solution they've come up with) to get them level.

It's worth the effort of getting sorted. Once everything is as it should be nice crisp 45deg chamfers are easlily repeatable.

Hope this helps.