The sliding table was making a slight catching noise. I unbolted the bearing housings on the sliding part so the theory was that the table would lift off and leave the bearings in place on the fixed part. Not quite. After lifting the top table off, two persons required with ball bearings falling everywhere, the cause of the catching sort of became apparent. You can see the two nylon ball bearing retainers and still on the fixed part, the bridge piece which has the shape of the retainers on the side skirts.

The nylon retainers were actually too long to fit in the space on the bridge piece. Maybe they had stretched a bit with continual use, but one end of each was just tucked behind the metal bridge piece, you can see the left hand end is a bit worn where it's been catching on something.

I cut 4-5mm off the length of each nylon retainer so they each fit snugly in the bridge piece.

The ball bearings were a bit grey but they were being replaced anyway with high quality stainless steel bearings.

Wadkin PP

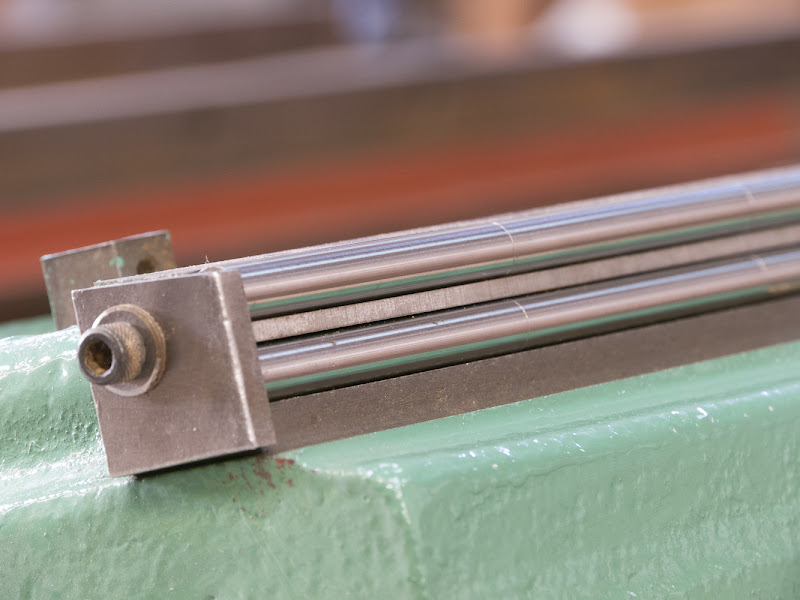

The sliding table travels on 144 steel rods, 3/8" diameter. By running a fingernail round each one, it's just possible to tell that there's a slight flat.

Wadkin PP

It was straightforward to dismantle the fixed part bearing housing and remove the rods. The casting looked like it had been machined last week. Here's the first steel rod going back, I made sure that the tiny flat was no longer in the line of the ball bearings. Effectively, a brand new section of rod was being presented to the ball bearings.

Wadkin PP

There's a line of steel rods, a steel spacer, and another line of rods, topped off with a steel bar which clamps it all down tight:

Wadkin PP

There's a cheese head machine screw for every position of steel rod, 18 each side in total, not taking any chances here that something might work loose:

Wadkin PP

The sliding part of the table was tricky. The rods are press fitted into a channel, the channel is fixed one side of the sliding table and adjustable the other. But I couldn't tell how hard it was going to be to get them out or if they had been pressed in on a machine. You can just see the wear line on the rod here:

Wadkin PP

I couldn't prise the rods out for fear of damage. So I had to prise out the centre steel strip. I hoped that after the first lift, the rest of the bar would pop out, but no, it was so securely held that it didn't move at all until the narrow screwdriver was well underneath the bar. Having started the job and being committed, I had to continue and accepted that the separator bars were going to get bent.

Wadkin PP

After removing all the rods and cleaning them up, I marked the wear line on each one, for quicker re-assembly:

Wadkin PP

The steel bars were fairly easy to straighten out and didn't appear to be any worse for the experience:

Wadkin PP

The bearing housing was easy to re-assemble, a line of 6 steel rods, put the separator bar in, then press the other 6 rods in the gap. Do this three times for each housing. This took a firm press with a piece of wood. Then double check that the bar and rods are fully seated, and make sure there's clearance under the ball bearing:

Wadkin PP

Here the top part of the sliding table is re-assembled and ready for turning over and putting on the fixed part, then insert the ball bearings in the nylon retainer and slide in:

Wadkin PP

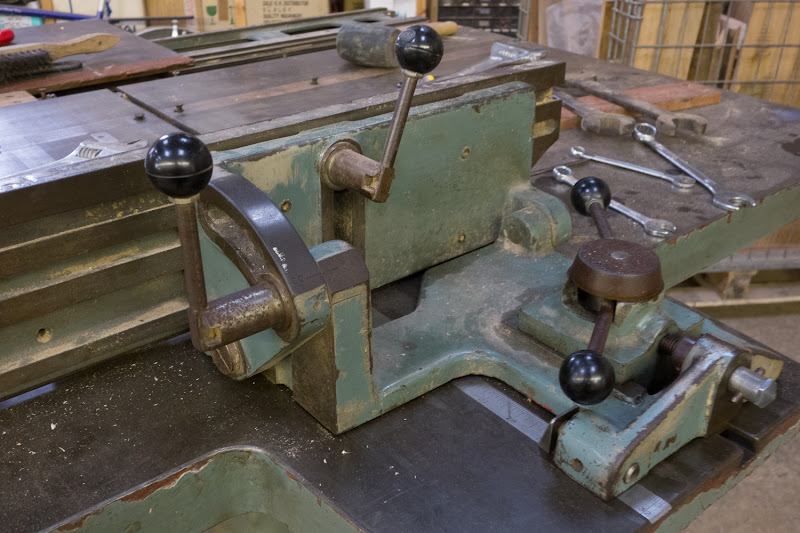

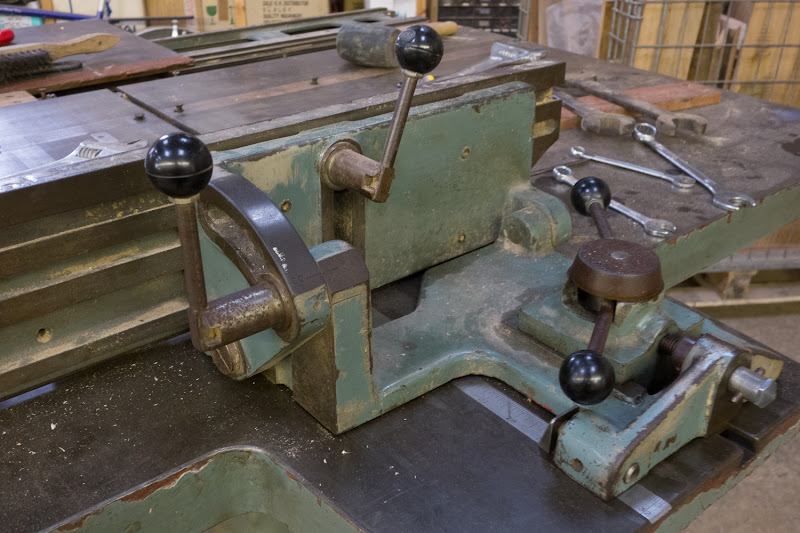

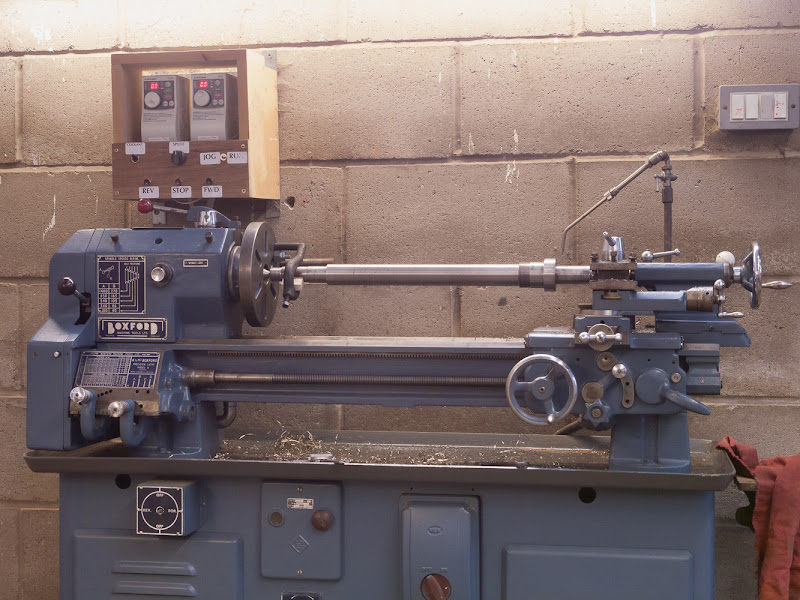

Here's a general view of the machine so far. It came off the pallet to its home position today. The sliding table is the nominal 4' model but it has about 54" of travel. Earlier I said that I didn't disturb the pins that were factory fitted. The sliding table is supported on 4 adjusters, 2 at each end and bolted to the main casting - I was prepared for some adjustment here. Maybe I would have to knock out the pins, slacken off the bolts and realign. A straight edge across the tables showed that they are in perfect alignment. The sliding table should be as good as new, with new ball bearings and and with the rods rotated to an unworn side. It's a heavy table but it rolls beautifully and even freewheels a little.

Wadkin PP

Here's the sliding table moved out for blade access. It's referenced to its home position by adjusters and stops on the main casting, that's something I'll deal with later:

Wadkin PP

This view shows the table fully extended:

Wadkin PP

More to follow