Andy Pullen":29a03aiq said:

So you would say that drawing a light RAS towards you is a safe way of working if you have a substantial timber to cut through ?

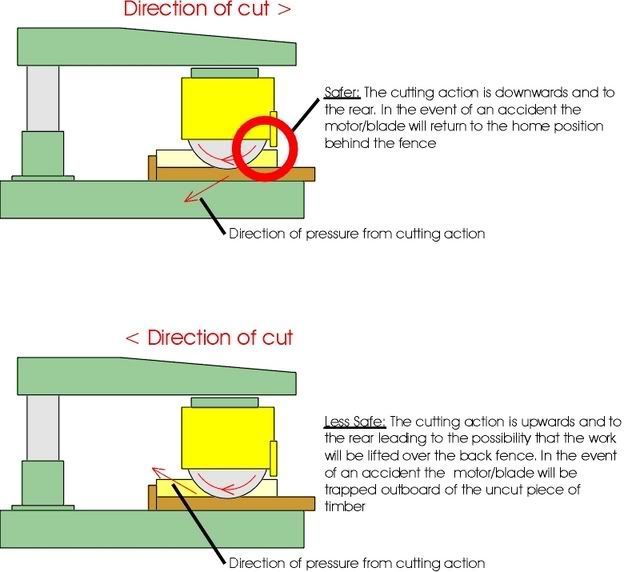

Yes. What I am also saying is that your approach seems downright dangerous and runs contrary to all my experience and training. I've gone so far as to produce a pair of drawings which explain why that is the case, Andy.

Andy Pullen":29a03aiq said:

Jerking, blade stopping, not my idea of fun.

Maybe a compromise would be to draw out for lighter cuts and in for heavy cuts. I understand exactly what you are saying but to my mind on a light machine it just aint safe, or particularly good for the machine to be constantly jarred and jammed.

Would you agree that a DW125 is a lightweight machine? After all it has a puny 1.5HP motor (and yet I can cut 16mm wide x 8mm deep housings with mine). I have rarely experienced the problems you mention for the following reasons:

1. The set-up of the RAS needs to be checked periodically to ensure that everything is in alignment, including the table surfaces and back fence

2. I always ensure that the blades are sharp

3. I almost always use a negative or zero rake blade. Positive rake blades are designed to work on table saws and will be jerky and try to climb or lift more readily on the RAS

4. I don't try to use a blade with too many teeth for deep cuts on the RAS, a 10in blade with 40 to 48 teeth will work very well except for cutting small section pieces such as beadings.

5. I avoid trying to cut knotty or badly bowed/warped timber on the RAS (or many other places for that matter)

6. If the machine is bogging down in cut then I try either reducing the speed of cut or turning the work over or

very rarely cutting in two passes. I also consider changing the blade and check that the blade and arm are both square to the back fence. It may also be worthwhile checking run-out on the blade. Mailee once had a problem where the inner blade flange was bent and I have seen bent arbors a couple of times (machines dropped in moving)

7. I never attempt to use a RAS for ripping (I did when I started using one in the 1970s). Now that can be really scary!

I've found that bogging down and cutting problems are more indicative of a poorly adjusted machine, damage or a blunt blade than anything else.

Andy Pullen":29a03aiq said:

Well you certainly wont get much consistency by back cutting with a light underpowered machine that is trying to jump over the work and similarly with your 12x2 oak example, how much fun trying to cut through that with a DW720. I can see a good argument for either way but thank you I'll do it a way I know I can control and that I feel safe with on a light machine. Held down against a fence it isn't going anywhere.

A DW1751 is the long arm version of the DW1251. The DW1251 is the predecessor of the DW720 but actually has

less power. I, and many others, have no problem with crosscutting on such a "small, underpowered" machine, yet you do, Andy. I'd really have to question if you've got either a set-up problem there, an incorrect/blunt blade or something is broken/bent, because my experience is the same as that of many other people. I do get consistent results cutting housings and I've used my lighter RAS with a dado head for short batch work with a more than acceptable level of consistency, so I suspect that there is something else wrong with your set-up, either that or you're a kitchen fitter....... :wink:

Scrit