Well here it is, delivered in the girlfriends flat.

First words where, "It's big isn't it?".

Some things that I encountered.

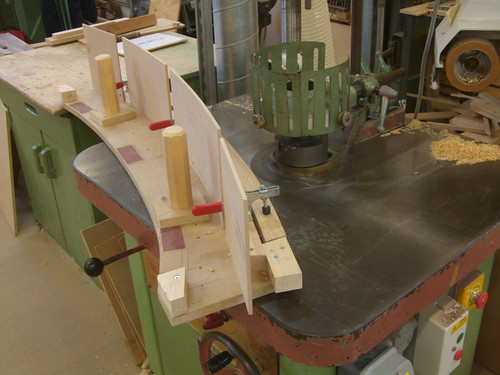

-The new top/bottom router bit was razor sharp so tare out was not an issue, took my time and made sure I moved the bit away from the work when I needed to change position so as to prevent that burn mark I usually get. When I routed the circle for the table I found that the cutter could not be plunged down on to the piece so I had to sort of juggle it into position whilst it was spinning, not recommended but I don't have a straight plunger that would have allowed me to get the first cut started and I didn't want to try and do this cut by hand.

-Once again the old saying of check all measurements twice and then do the cut proved too late. I somehow Domino'd the legs before putting the angled cut on them so when it came to attaching the legs to the base of the table they just sat at 90 Degrees to the piece so had to re-plung at 5 degrees into the bottom of the table, fortunately there was enough room in the base so my mistake was hidden.

-Wax. Not a good idea to apply a heavy first coat and leave in a freezing workshop over night. It was like a thick varnish when I returned the following morning and had to rub it down with some 0000 steel wool and then apply another coat.

-Don't let the dog dribble on the newly applied wax!!. Those lovely white marks that water leaves on fresh wax is not the look I wanted so once again, lightly 0000 wired and then re applied.

Thanks for your help guys.