A common cause of this is overfeeding a blade with too many teeth (not enough gullet space to clear the waste) but with a 24 you shouldn't be having that problem.

Another issue, as mentioned above, is run out. It is of some use to check the blade whilst it is cold, as this will show any serious warping. However it is also worth considering that when you are using it you are heating the perimiter to serious temperatures - clearly enough to burn the face of the timber in the split second that the two are in contact - but the centre of the blade is spinning in fresh air and being cooled. This temperature difference can cause a blade that is flat whilst cool to take on the shape of a pringle when working.

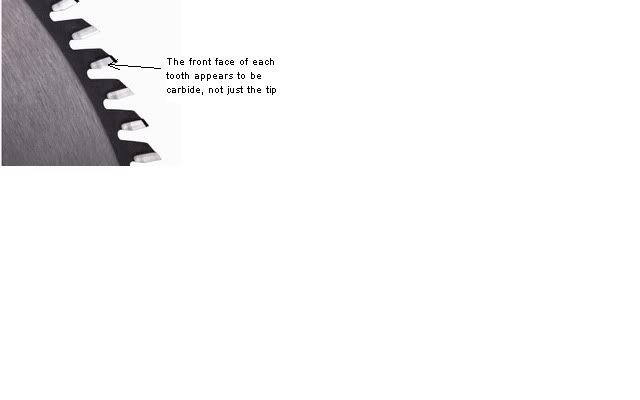

This is exactly the issue that hand smithing sorts out. The plate is hardened and tempered under pressure which makes the crystalline structure of the steel form flat in the first place. It is then smythed by repeatedly hammering the plate and obsering how it falls away from a straight edge, so the internal tensions within the plate also make it want to remain flat and round. The result is a blade that will expand very slightly in its circumferance when differentially heated, but it will not warp or twist. They are precision ground rather than merely polished, and fitted with big fat micrograin tungsten carbide teeth that can be resharpened.

I was lucky enough to be allowed not only to watch the smiths at Atkinson Walker in action but also video them on a recent visit to the factory in Sheffield (available on youtube as soon as I find time to upload it). Not so long ago they would have downed tools and folded their arms the moment I walked into their shop. The only way you learned how to smith a sawblade was by doing a full 5 year apprenticeship, there's no 'tricks of the trade' malarky in this game thank you very much!

Thankfully things have relaxed as the trade is now in danger of being lost - there are only a handful of qualified smiths left in the country so the Sawsmiths are keen on anything that will encourage youngsters to take up the trade.

All of the

industrial blades that we sell are treated in this way and can be returned to the factory for resharpening up to ten times. In most cases, by the time you take into account how many ordinary blades you would get through in the lifetime of an industrial blade, the savings run into hundreds of pounds - and that's on top of the performance benefits.