Simon A Wells

Member

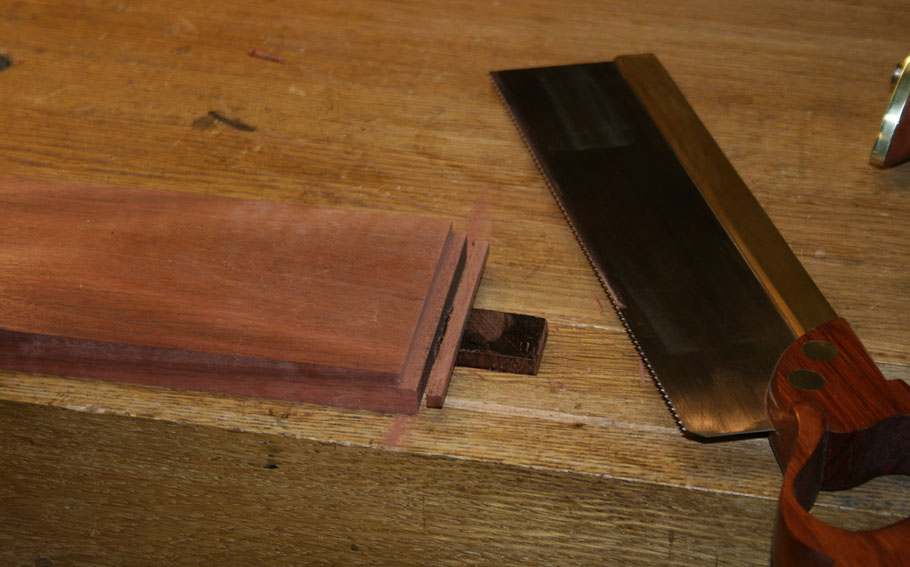

I have a number of projects that need / I would like to have sliding dovetails:

I am a hobby woodworker in a double garage with a contractor table saw 255mm, record morticer, makita trim router (240V) and rather to many hand saws and planes.

I have looked at a number of soloutions, lots of youtube and am wondering if there is a simple, repeatable way to cut the male tennon piece?

The female part seems pretty straight forward with a router.

I have just finished a 6ft by 6ft table saw work bench with matchfit microjig dovetail groves on top and on two of the side panels, so no problem with routing dovetail grooves!

I have looked at:

I don't mind investing in a tool / jig system, but would rather buy wood....

I have anther thread on woodrats for a hobby workshop / sliding dovetails here: https://www.ukworkshop.co.uk/threads/woodrat-for-hobby-woodworkers.150971/

- Large heavy bench / shoe storage from 2 inch pine that would need about 18 slidding dovetail, exposed at both ends, so not stopped.

- Book cases / office storage.

I am a hobby woodworker in a double garage with a contractor table saw 255mm, record morticer, makita trim router (240V) and rather to many hand saws and planes.

I have looked at a number of soloutions, lots of youtube and am wondering if there is a simple, repeatable way to cut the male tennon piece?

The female part seems pretty straight forward with a router.

I have just finished a 6ft by 6ft table saw work bench with matchfit microjig dovetail groves on top and on two of the side panels, so no problem with routing dovetail grooves!

I have looked at:

- shop built jigs like this https://www.finewoodworking.com/200...4lZlTM-ajMFfvqBg2oMjSlgq394w1RXuonnVIv0IslzQm

- Woodrat

- Leigh dovetail jigs

- Router tables

I don't mind investing in a tool / jig system, but would rather buy wood....

I have anther thread on woodrats for a hobby workshop / sliding dovetails here: https://www.ukworkshop.co.uk/threads/woodrat-for-hobby-woodworkers.150971/

Last edited: