Pardon another tangent gents.

50°??Paddy Roxburgh":349azcmv said:the 50 degree blade for my block plane

50°??Paddy Roxburgh":349azcmv said:the 50 degree blade for my block plane

ED65":32mhqa4l said:Pardon another tangent gents.

50°??Paddy Roxburgh":32mhqa4l said:the 50 degree blade for my block plane

Jacob":328ic7x0 said:Tricky if you want the precise angle - but nobody actually needs this.Peter Sefton":328ic7x0 said:...

Sounds like a very sensible solution and you are right learning to sharpen at 30 degrees is one thing mastering 35, 38 and 50 is more tricky. ....

"Mastering" doesn't come into it. Any fool can do it it doesn't take 6 years. 20 minutes more like.

in the real world; 50 would be "a bit more than 45", 35 ditto 30, 38 ditto 35. 25 is a bit less than 30. That's how freehand sharpening works - and it does work. .

Eric The Viking":2xb4vj29 said:With due deference to both David C. and Peter S., if 'twere me, I'd teach scary sharp first**. This is simply because the student then learns what a suitably sharp edge actually is, and that they really can do it for themselves. That boosted my confidence enormously. And I now know what I'm looking for when I experiment with other methods.

CStanford":hm0z9j77 said:THE GRIND

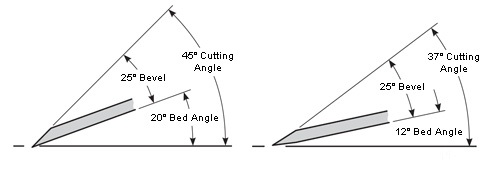

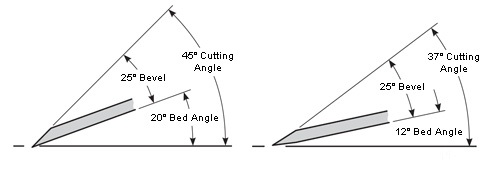

Next we grind our blades to twenty-five degrees. This is a general all round all purpose grinding angle. Pairing chisels maybe ground slightly lower and chopping blades slightly higher. But this is the general all purpose. Grinding we do on a Tormek water stone, or, if you know what you're doing, on a bench grinder. We don't use slowed down special grinders but we do form the surface of the grindstone with a diamond stone to a slight dome. So that the stone is only cutting one spot. That way by moving the blade across the grindstone we can keep the edge cool. Our grinder is also setup with a workshop made tool rest which just helps us locate the tool and present it cleanly to the grindstone and move it around easily in front of the stone.

HONING THE MICRO BEVEL

The Japanese hone the entire surface and most of the Japanese blades are ground at an angle of thirty degrees. This is too high for Western work and I think honing the whole of that surface is a waste of time. We just hone a micro bevel on the front like we do all our European blades. We hone without honing guides, again, because of speed. I know this is fighting talk but at Rowden we wouldn't employ anybody who has to use a honing guide to sharpen blades.

NO TRAINING WHEELS AT ROWDEN

It's a different matter, however, if you're not doing this work to earn your living, then just don't worry about it, take your time, use what jigs you need and get it right.

MIGNAL":25pon2cu said:Personally I'd teach the two stone method. Actually one stone and the grinder. Simple, you only have to buy the one stone and you have access to something that will take out serious nicks. I also use the grinder to reform old files into knives and little cutting blades from worn needle files etc.

Oh and it suits both freehand and jigs too. SIC paper is cheap to start. In the long run it will work out very expensive but obviously depends how much woodworking one actually does. For a professional the paper is an expensive method of sharpening.

Could start another hare here - but in fact training wheels for bikes are deprecated - they can have completely the wrong effect and actually de-stabilise the rider. They can make things more difficult. I speak as parent, grandparent of a large mob of cyclists!phil.p":3eoh7av1 said:That's an interesting observation. Maybe the jig acts like training wheels on a bike? ....

Wrong.iNewbie":3hxwgyu1 said:.....

And this 20 minute knowledge came after you couldn't freehand for years and bought some Jigs?

Jacob":2retwmfz said:iNewbie":2retwmfz said:.....

And this 20 minute knowledge came after you couldn't freehand for years and bought some Jigs?

Wrong.

I could freehand perfectly well - I learnt it at school. But like a lot of people I was seduced by the promise of "progress, new improved levels of precision etc etc only obtainable with a jig". It took some years to realise that this was a delusion and in fact led to a whole rake of other problems. The only advantage being those trim looking precise bevels, which don't of themselves constitute sharpness.

iNewbie":ww87y9vw said:Corneel. Its all about the humour for me. :wink:

Good question - the answer was promises of even greater perfection!iNewbie":ktk16a5j said:... Why follow a Pied Piper when you've got the edge.

The eureka moment on the road re-discover was noticing the rounded bevels on so many old chisels and plane blades, including the Japanese. It occurred to me that they couldn't all be wrong. 10 minutes later I discovered that they were right! :lol:......

If you can do one chisel well theres no need to practice on 99 or more...

...