Cheers Klaus...that's praise indeed!

Ok the saga of the mill now being sorted...and the new lever cap having arrived via Andy...THANKS PROF!! from Bristol Designs...(isn't Charles a gem!)...I decided to take the raw casting to a rough shape with the mill and then finish by hand.

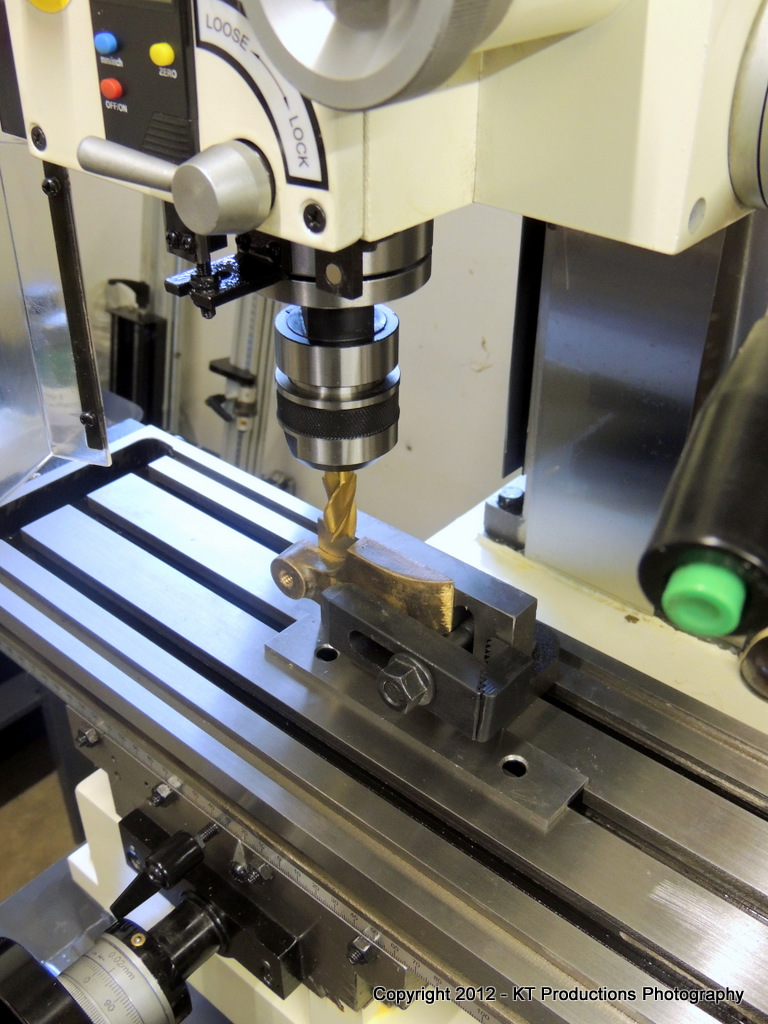

Bit of an overkill for this job...but what the heck! (Hand Tool obsessives please look away now!!!! :mrgreen: )

ALFIE helped!

Now before any black stuff whizzers out there criticises the setup and results....I have to point out that ALFIE has not actually done any milling before so please excuse him!

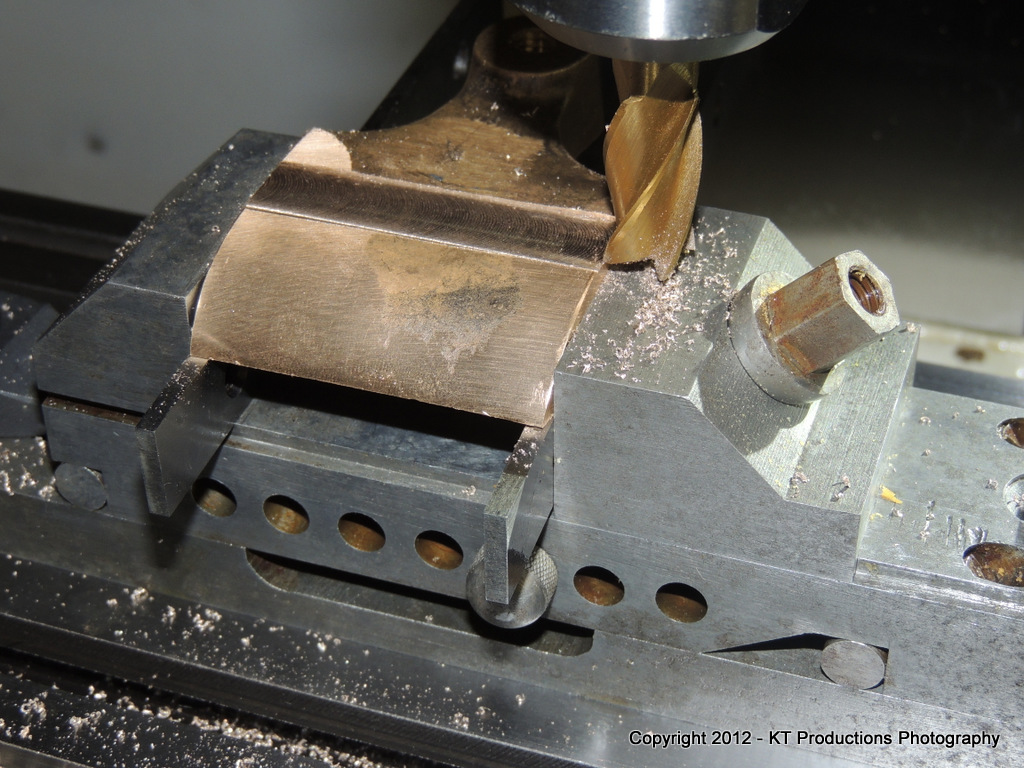

After removing most of the casting rough bits with a file...we clamped it tightly against an angle plate....

...to square up the sides...

...which worked nicely...

...and meant it could then be fitted safely in a sine vise to finish the top...

...as there was some quite deep casting pits.

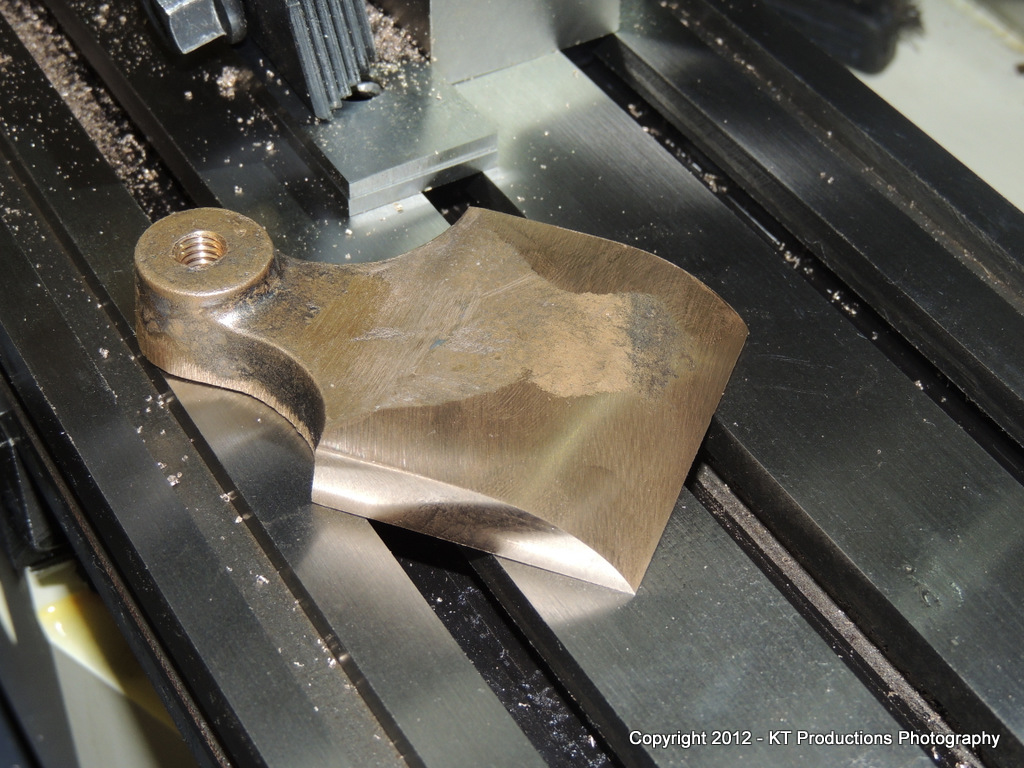

After most of this was removed a quick disc sand and we can see what we are doing...

After finishing the top bits by hand (I haven't quite got used to the rotary table yet

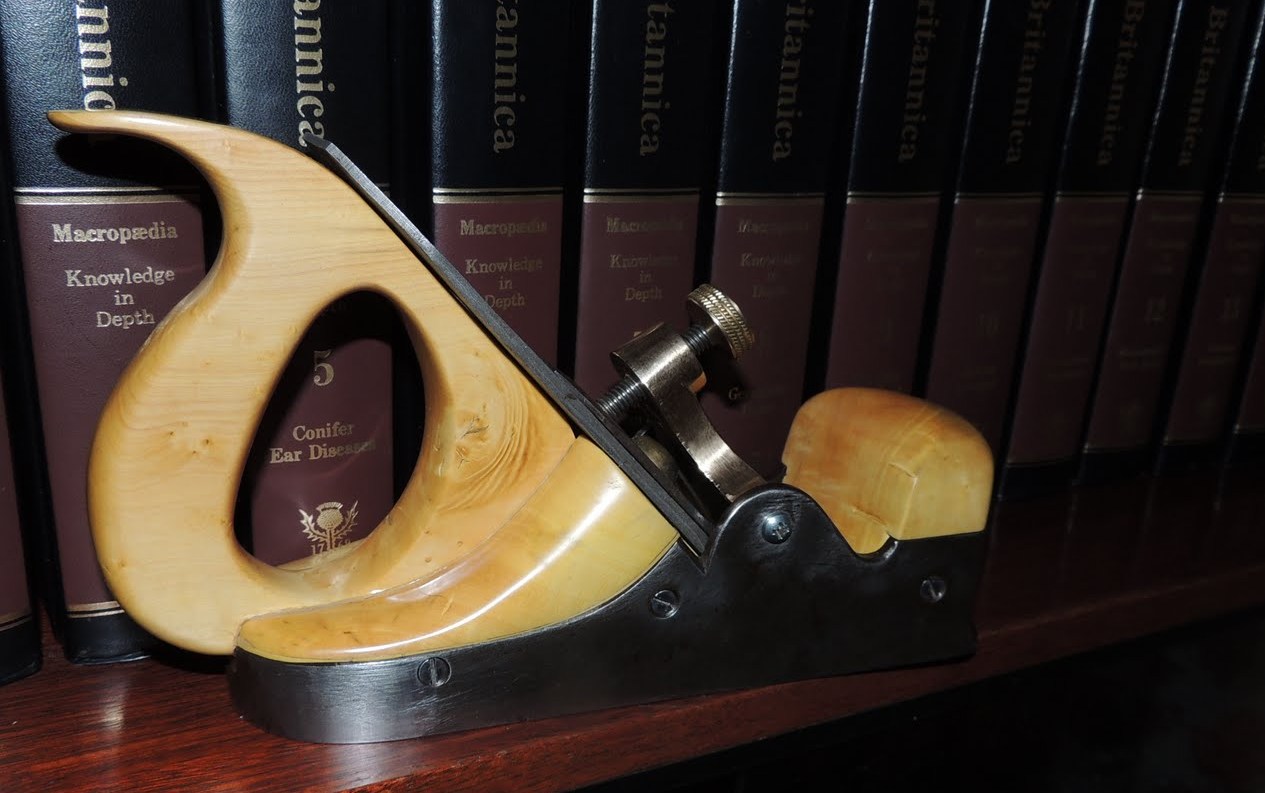

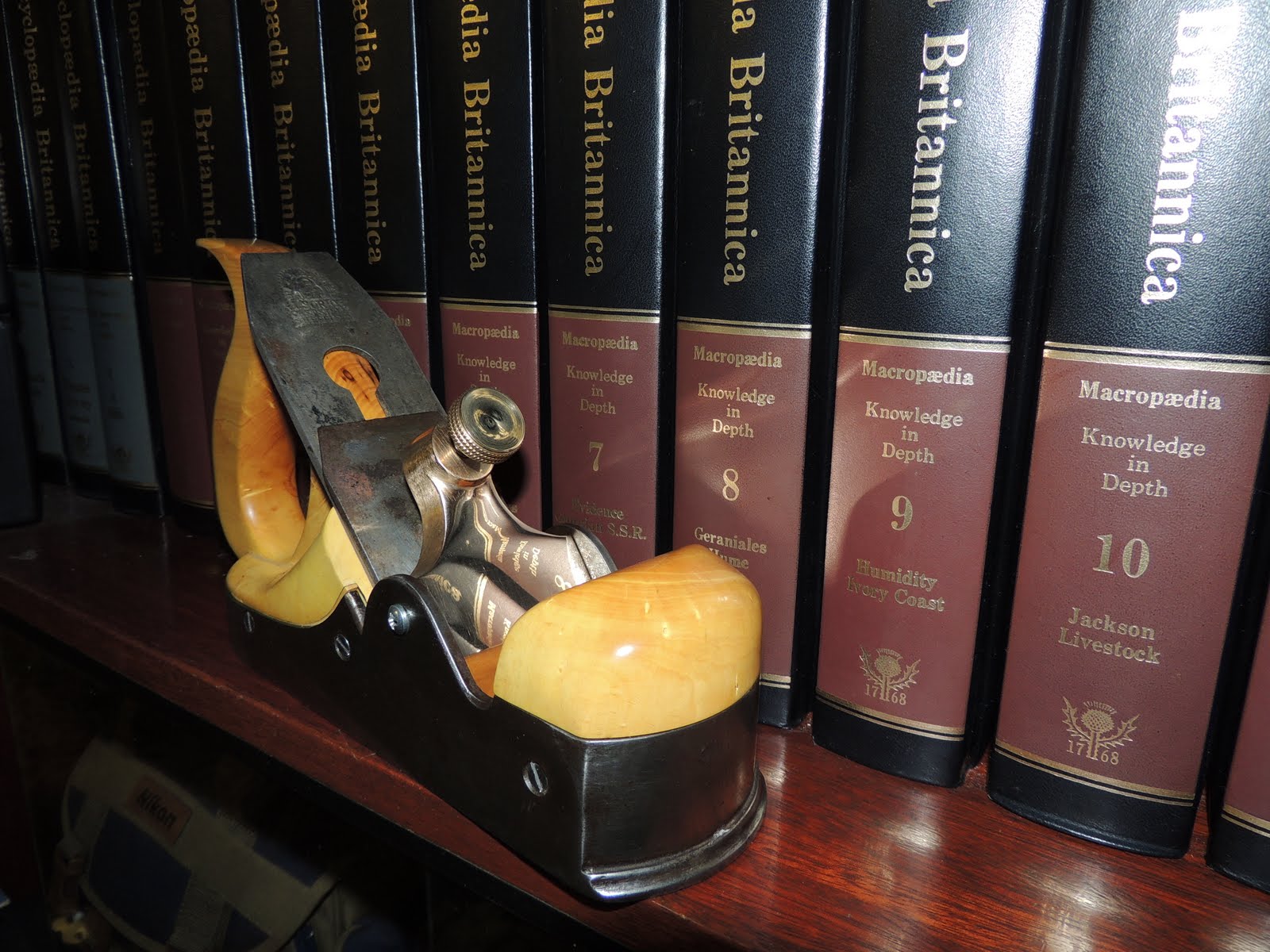

....I fitted it to the plane to see how it looked...

A few scratches which I need to get out...a bit of "ageing" to do but it looks the part!!!

Sorry Richard...I could have done the whole thing with files in about half the time but I wanted to play with the new toy...

I promise to do your one by hand...or at least finish it by hand...WHEN I finally either get a larger casting or I get a suitable bit of bronze/gunmetal (still looking! #-o )

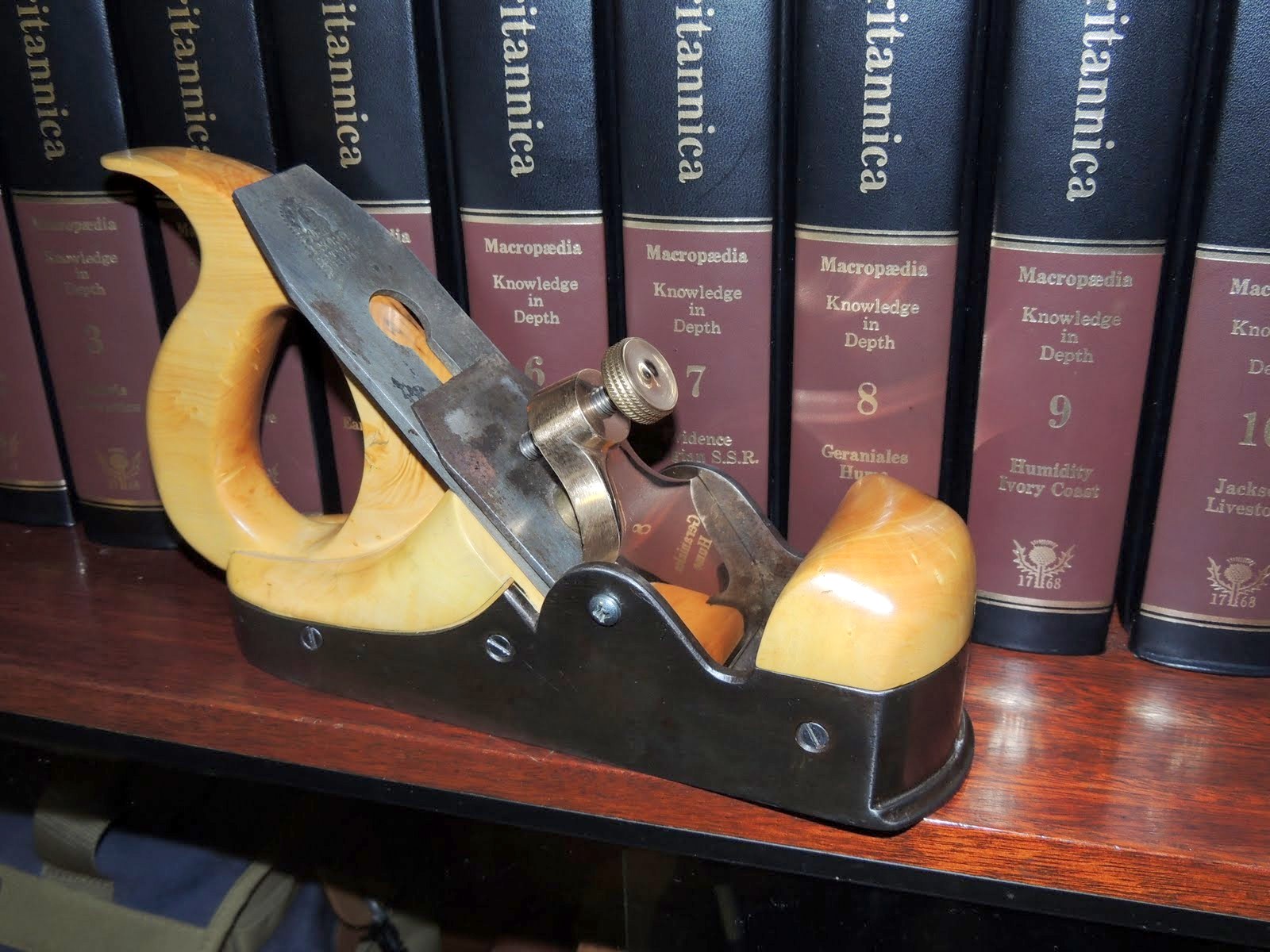

So...before I subject the whole thing to final finishing...a few shots of the plane in action on some particularly nasty oak...reversing grain...knots...the works...

Boy...did that make a difference...!!

Whizzed through this old oak...even the knot....

....leaving a mirror finish!

...and that's just with a little old 100+ year old I.Sorby!

Ok....I will now hit it with the linseed oil find some old bolts for the lever cap to replace those temporary ones (you did noticed didn't you? :mrgreen: ) and then start looking seriously for some proper stock for the jointer.....

But in the meantime...why not make an iron blank on the mill first!

More on that in the other thread later!

Cheers for all the help Andy!!

Jim