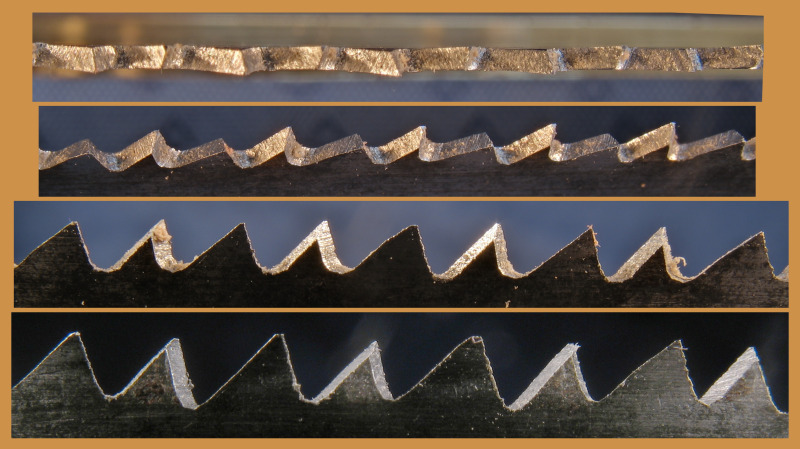

Since several people expressed an interest, here's the low down on how I

got those photos.

Executive summary:

it wasn't point 'n' shoot; it involved lots of light, close focus, HDR.

The long version...

The problem with saw teeth is that they're small,

and made from shiny metal. The size problem

is easy to get round if your camera will focus

VERY close. Mine will (many compact digital cameras will).

It's a Canon A630,

http://www.dpreview.com/reviews/specs/C ... n_a630.asp

and will focus down to 1 cm (under 1/2 inch, Paddy).

It also has manual focus (that's a pain

to use, but it has it).

The problem then becomes one of how do you

get a camera so very close to the subject;

I have a Benbo Trecker tripod, where the main

column can be adjusted to be horizontal, and the camera

facing down. I have often used this to get

"looking down" shots on flat items (books, saws etc).

link

http://tinyurl.com/3d9phs

But in this mode the only way to adjust the height

is by adjusting all 3 legs on the tripod, which is tedious.

I adjourned to my workshop and made a tripod-extension-widget:

http://galootcentral.com/components/cpg ... extend.jpg

This simply has a standard mount thread (1/4" UNC) at one end

(from Lee Valley, thanks to ALF)

http://www.leevalley.com/wood/page.aspx ... 3455,52800

and a camera fixing bolt (same spec...) at the other. In the middle

it's a simple sliding slot, held by a 1/4" bolt and wingnut. This allowed

the camera's height to be fine adjusted easily. This extension ain't exactly

rigid, but it's fine indoors, where there's no wind, and I use

a shutter delay of 5 second to allow

any movement generated by camera handling (pressing the shutter) to die down.

http://galootcentral.com/components/cpg ... _close.jpg

The light is supplied by 4 angle poise lamps; using multiple

light sources reduce shadows.

http://galootcentral.com/components/cpg ... p_long.jpg

Of course, if you simply take a photgraph under these circumstances,

you will encounter major issues with over/under exposure, since

saw teeth (especially freshly filed ones) are rather shiny.

The answer is HDR, which has been described elsewhere better

than I can do it:

http://en.wikipedia.org/wiki/High_dynamic_range_imaging

The task at the point of taking the photographs is to shoot

a "bracketed set"; a range of otherwise identical photos

which vary only in shutter speed. Some cameras

have built in support for this, but mine doesn't. However,

with the CHDK third party software, it can be added.

http://chdk.wikia.com/wiki/Main_Page

I set the shutter speed bracketing value to 1 2/3 EV,

http://chdk.wikia.com/wiki/CHDK_firmwar ... ting_value

and used "custom" drive mode, with 5 second delay, taking 5 photographs.

This gives me a massive overall EV range, the defining property of HDR.

I then downloaded the photos to my Linux laptop (Fedora FC8)

I used the "enfuse" program to merge them; since I only wanted

the saw teeth, I cropped that part of the image from each photo

to avoid unwanted pixels influencing the HDR merge operation.

http://wiki.panotools.org/Enfuse

Since the sawteeth image is pretty much monochrome, and

I was simply trying to get a "good" exposure I used the

following enfuse options:

enfuse -o output.jpg --wExposure=1.0 --wSaturation=0.1 --wContrast=0.1 --compression=92

followed by a list of input files.

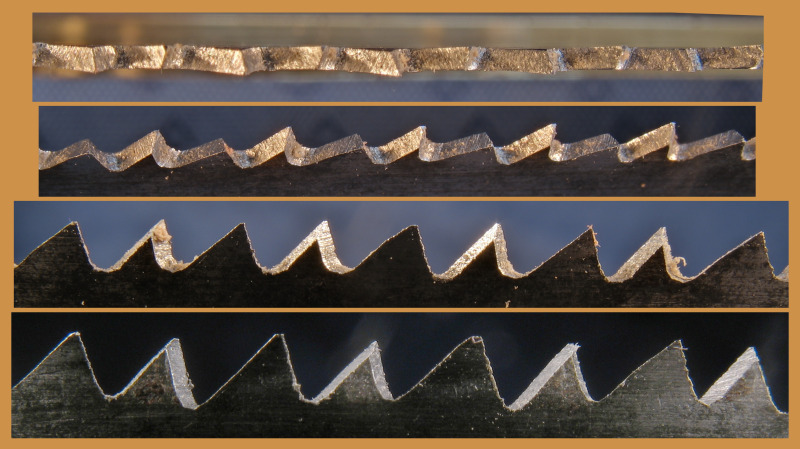

To get the side shot of the teeth, I used another, more usual, tripod,

a Gitzo Tatalux Reporter,

http://groups.google.com/group/rec.phot ... fb34edad03

http://tinyurl.com/2ml8gq

and again used my home-brew extension for final position of the camera:

http://galootcentral.com/components/cpg ... _close.jpg

All other aspects "as before".

I hope this has been of at least some interest to at least

some member of the Porch. Since many of the choices I made

were driven by equipment or facilities I happen to have, I would

not expect anyone to follow what I did in all details, but I hope

it offers guidance or inspiration as to what is possible.

BugBear

Fourth photo added, after re-file with smaller file.

Fourth photo added, after re-file with smaller file.