devonwoody

Established Member

I hand cut a lifting knob for the box above, ( well used saw board.)

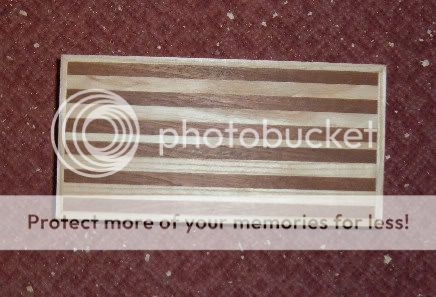

And started another ribbed box, Sapele and American Ash, (that will make three ribbed boxes, and three visitors coming to stay this weekend, so I will have to get cracking)

prepared to 10mm thick strips.

And hand cut them to length (decided to do some handwork for a change, but knocked up a useful jig) I have put the saw board in the vice and clamped a length stop to the bench, now every one of the 32 lengths have cut nicely to equal sizes.

Brought them indoors to glue up for the night. so that was a good day.

And started another ribbed box, Sapele and American Ash, (that will make three ribbed boxes, and three visitors coming to stay this weekend, so I will have to get cracking)

prepared to 10mm thick strips.

And hand cut them to length (decided to do some handwork for a change, but knocked up a useful jig) I have put the saw board in the vice and clamped a length stop to the bench, now every one of the 32 lengths have cut nicely to equal sizes.

Brought them indoors to glue up for the night. so that was a good day.