This is really helpful. Thanks for sharing.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Night stands - power and hand together

- Thread starter Derek Cohen (Perth Oz)

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Derek Cohen (Perth Oz)

Established Member

Interesting method of turning the tapered legs.

IMO, you made much more work for yourself but you got the results you wanted.

I also don't usually see turnings with the larger diameter at the tailstock end, this is opposite of what most people do. A template or story stick is often enough to mark diameters at intervals along the turning and connect the sections.

Admin at:

(The Woodturning Forum - Woodturner's Resource - Index)

Ed, I have done this a number of ways in the past. Creating the taper on the stock, and then turning it round is the fastest and most accurate method I have used. A story stick with sizings makes for more work - having to measure constantly. Here all I do is round off the stock, and it is done, and accurately to the chosen size.

The reason the large diameter is at the tailstock is that it creates less damage to the end. The headstock end, where a greater number of impressed marks are made, ends up under the leg.

How would you do this?

Regards from Perth

Derek

Derek Cohen (Perth Oz)

Established Member

It's beginning to look like a nightstand!

The project ended last time with all the parts cut and shaped for the two bases ..

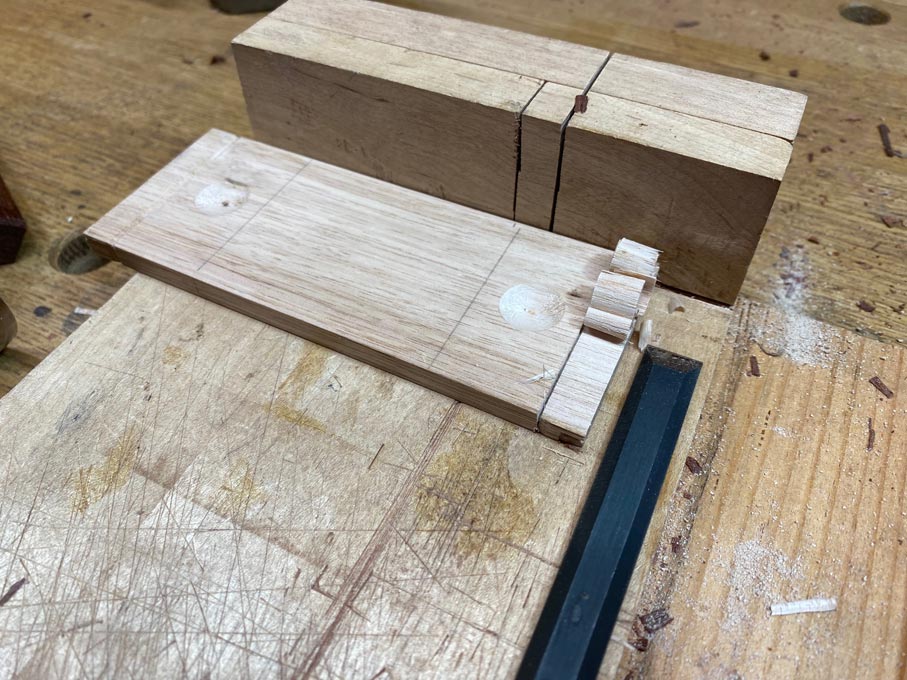

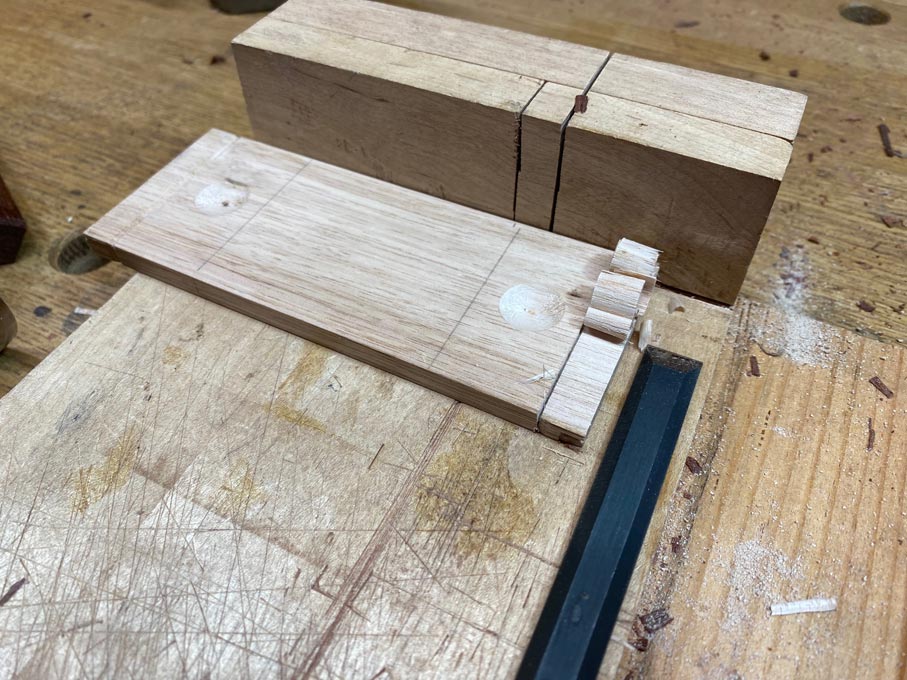

Square peg into a round hole? Not quite, but the square ends of the aprons must join flush with the round legs ...

The choice was either to cope the end face of the apron to match each leg, or to shape the leg to match the end of the apron. I decided on the latter as each leg had a taper and the ends of the aprons were angled at 3 degrees. Matching the legs seemed much simpler. Still, it would prove to be a fair amount of work.

Step 1 - mark out the recess:

Step 2 - chop out the waste with a chisel:

The fit is decent ...

Eight joints later, and the first stage of the first base is at glue-up stage ...

Tapers round legs splayed at 3 degrees ...

The rounded front can be seen here ...

Close up off joints ...

I couldn't resist a little mock-up (but lots still to do - not only that this is one of two) ...

Regards from Perth

Derek

The project ended last time with all the parts cut and shaped for the two bases ..

Square peg into a round hole? Not quite, but the square ends of the aprons must join flush with the round legs ...

The choice was either to cope the end face of the apron to match each leg, or to shape the leg to match the end of the apron. I decided on the latter as each leg had a taper and the ends of the aprons were angled at 3 degrees. Matching the legs seemed much simpler. Still, it would prove to be a fair amount of work.

Step 1 - mark out the recess:

Step 2 - chop out the waste with a chisel:

The fit is decent ...

Eight joints later, and the first stage of the first base is at glue-up stage ...

Tapers round legs splayed at 3 degrees ...

The rounded front can be seen here ...

Close up off joints ...

I couldn't resist a little mock-up (but lots still to do - not only that this is one of two) ...

Regards from Perth

Derek

Last edited:

Derek Cohen (Perth Oz)

Established Member

Skyhooks

Last time the nightstand build ended with a mock up of one nightstand ..

Here steel nuts were used to lift the cabinet off the base. This weekend I completed the second base. Here are the two with the cabinets resting on the bases ...

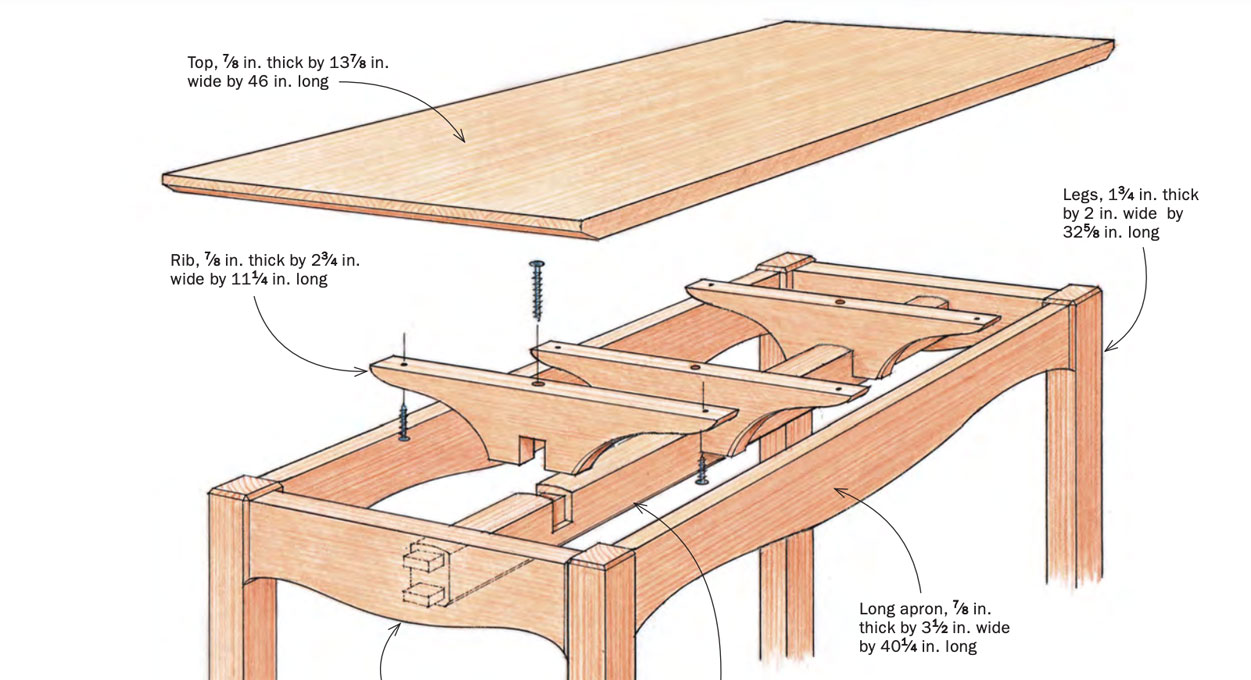

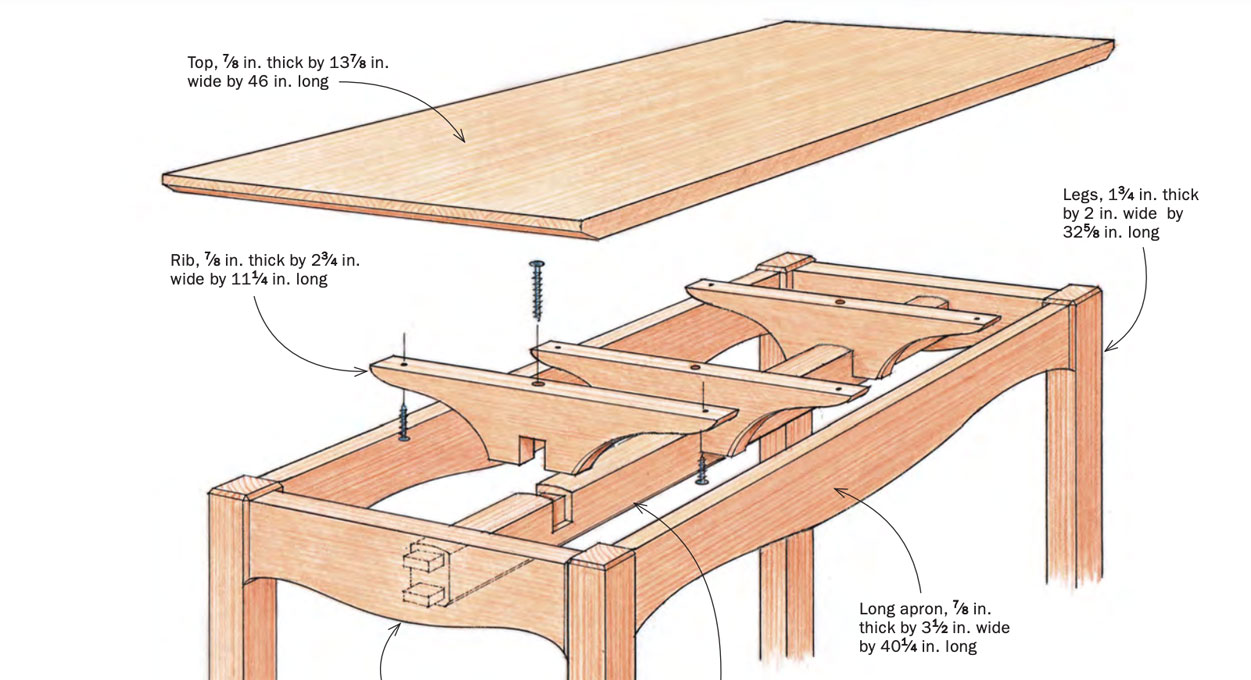

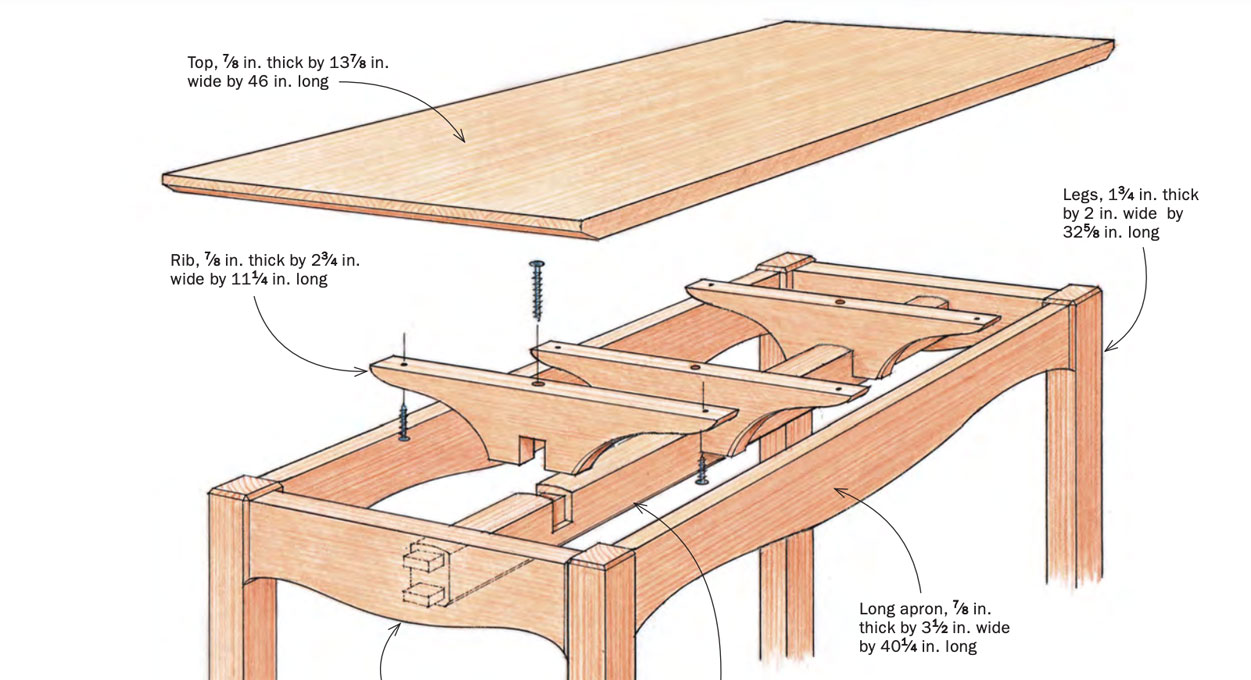

I had been planning to construct the floating appearance by using a slight variation of this construction ...

... but the example with the nuts had me thinking if there was another way, one less observable from the side.

Here is a mock up again, taken today ...

I came up with this linkage, and what I am after is some opinion as to how secure you imagine it will be.

These simply began as Jarrah triangles, and were shaped to reduce unnecessary bulk (which might be visible). All legs are 10mm thick x 18mm wide ...

For greatest strength, the grain runs across the bracket.

The one side was coped to fit flush with the round leg ...

This is how it is intended to be fitted ...

Here is the mating of the coped inside with the outside of the round leg ...

The plan is to glue and screw the coped side. The glue joint should create a strong connection, and a screw will just provide extra support. The cabinets will be screwed to the top of the bracket.

Opinions and ideas?

Regards from Perth

Derek

Last time the nightstand build ended with a mock up of one nightstand ..

Here steel nuts were used to lift the cabinet off the base. This weekend I completed the second base. Here are the two with the cabinets resting on the bases ...

I had been planning to construct the floating appearance by using a slight variation of this construction ...

... but the example with the nuts had me thinking if there was another way, one less observable from the side.

Here is a mock up again, taken today ...

I came up with this linkage, and what I am after is some opinion as to how secure you imagine it will be.

These simply began as Jarrah triangles, and were shaped to reduce unnecessary bulk (which might be visible). All legs are 10mm thick x 18mm wide ...

For greatest strength, the grain runs across the bracket.

The one side was coped to fit flush with the round leg ...

This is how it is intended to be fitted ...

Here is the mating of the coped inside with the outside of the round leg ...

The plan is to glue and screw the coped side. The glue joint should create a strong connection, and a screw will just provide extra support. The cabinets will be screwed to the top of the bracket.

Opinions and ideas?

Regards from Perth

Derek

Hi DerekSkyhooks

Last time the nightstand build ended with a mock up of one nightstand ..

Here steel nuts were used to lift the cabinet off the base. This weekend I completed the second base. Here are the two with the cabinets resting on the bases ...

I had been planning to construct the floating appearance by using a slight variation of this construction ...

... but the example with the nuts had me thinking if there was another way, one less observable from the side.

Here is a mock up again, taken today ...

I came up with this linkage, and what I am after is some opinion as to how secure you imagine it will be.

These simply began as Jarrah triangles, and were shaped to reduce unnecessary bulk (which might be visible). All legs are 10mm thick x 18mm wide ...

For greatest strength, the grain runs across the bracket.

The one side was coped to fit flush with the round leg ...

This is how it is intended to be fitted ...

Here is the mating of the coped inside with the outside of the round leg ...

The plan is to glue and screw the coped side. The glue joint should create a strong connection, and a screw will just provide extra support. The cabinets will be screwed to the top of the bracket.

Opinions and ideas?

Regards from Perth

Derek

To allow for expansion/contraction of the solid wood construction i would screw the top box to the front brackets, from underneath.

I would screw a piece of brass to the rear brackets, that I would rebate into the top box.

I would cut a slot into the brass, so that the screws, when fitted to the top would be able to slide, allowing for the expansion/contraction of the wood.

That's my pennies worth

Fred

I like to cope the ends of the rails as you say. It's quite easy to drill vertically from the top using the outer edge of a good forstner bit matched to the diameter of the legs. Needless to say the rails need to be clamped to the bed of the drill press.

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£19.34 (£3.87 / count)

£19.99 (£4.00 / count)

Stealth Lite Pro FFP3 Face Masks UK Certified Dust Mask. 99.99% particle filtration, air filter reusable face mask. FFP3 Mask -7 day use per Construction, Woodworking, DIY and Welding Mask

Amazon.co.uk

£13.99 (£2.80 / count)

VEVOX® FFP1 Dust Mask - Set of 5 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

Derek Cohen (Perth Oz)

Established Member

I literally woke up in the middle of the night (it happens when one is 73) and considered what would happen if the construction was tipped over on its side. The strength of the bracket is weak in lateral movement - perhaps not these, but in design. Consequently, this is not the connection I want to use, and I will go back to Plan A.

Regards from Perth

Derek

Regards from Perth

Derek

Jester129

Established Member

It would still look great with the wood fitment though - more perceived 'floating' IMHO. HTH.

Derek Cohen (Perth Oz)

Established Member

The Power of the Press

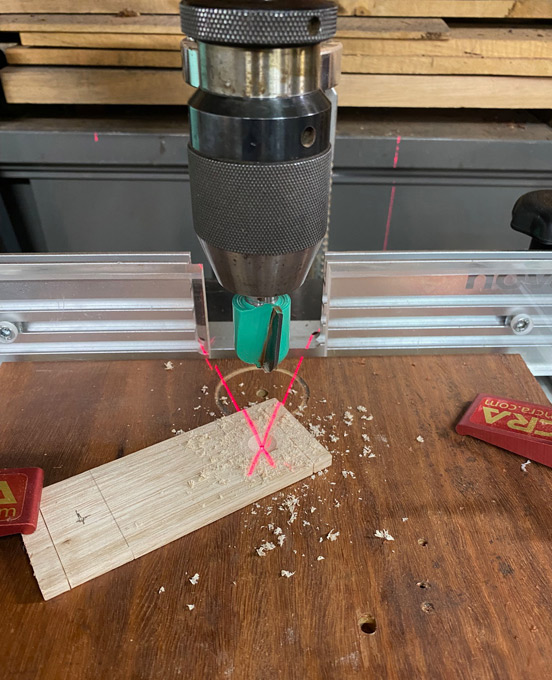

The drill press, that is.

This is one of those machines I do not want to be without. It has many uses, and today it was used to shape the ends of the risers for the floating cabinets. Not much in the way of hand skills here today.

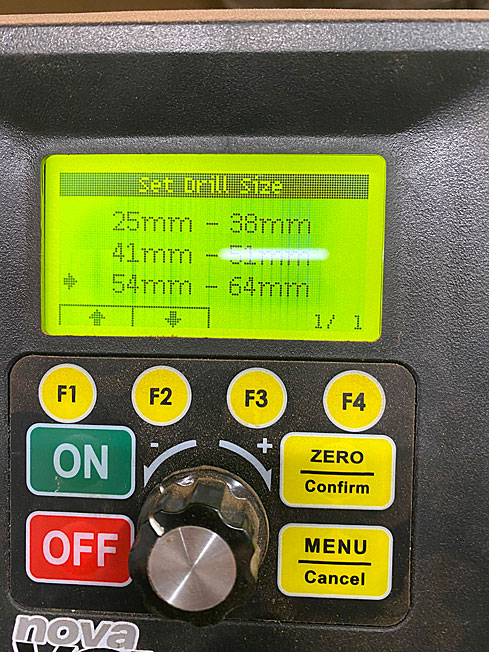

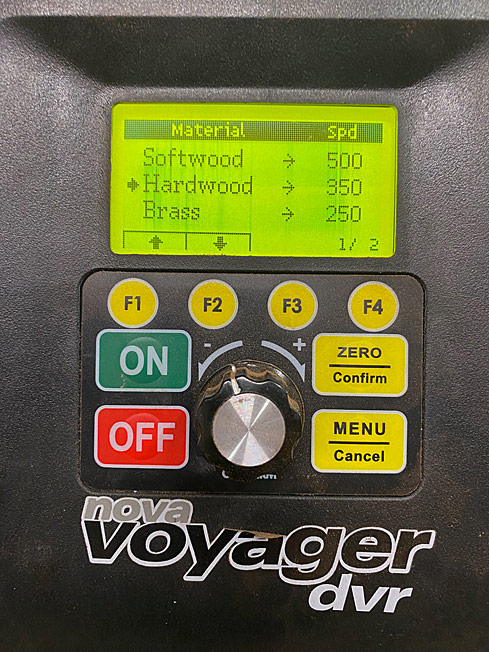

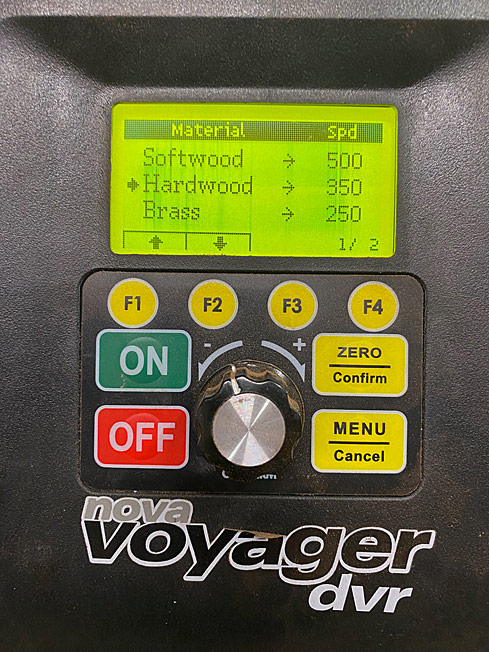

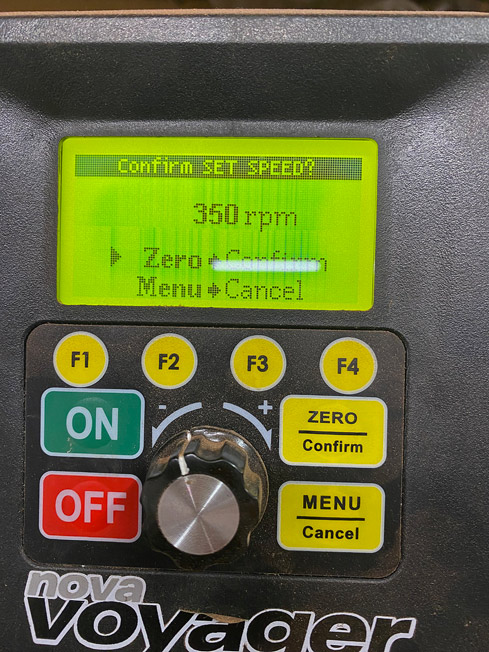

I purchased the Nova Voyager about 5 years ago courtesy of a Black Friday special and a kind-hearted wife. This replaced a close-to-entry-level 12-speed Taiwanese press I had for about 25 years. For those unfamiliar with the Voyager, here is one feature that I find so amazing about this machine.

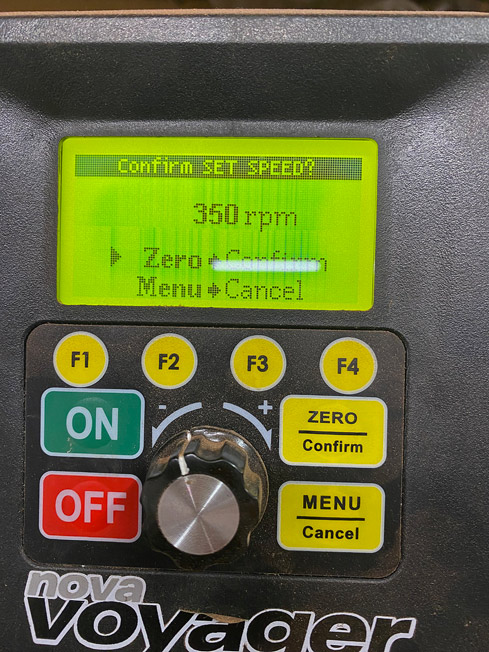

In all the time I have used this drill press I have yet to burn a blade or wood. A few buttons to push, and you can set any type of drill bit, of any size, to turn at the ideal speed for different densities of wood (or metal).

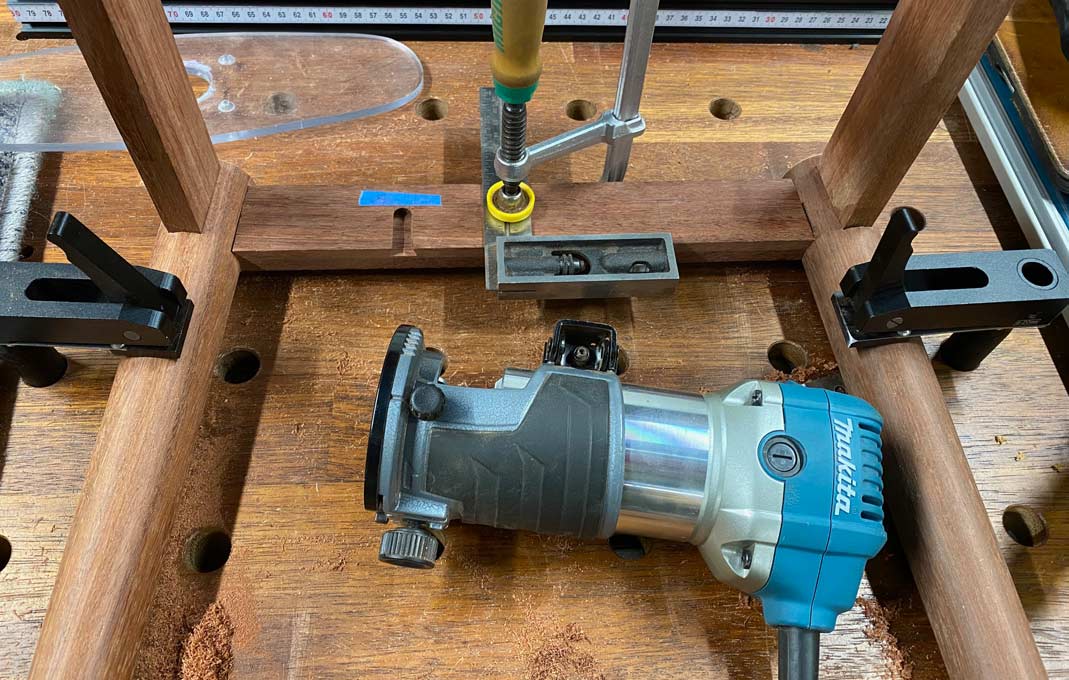

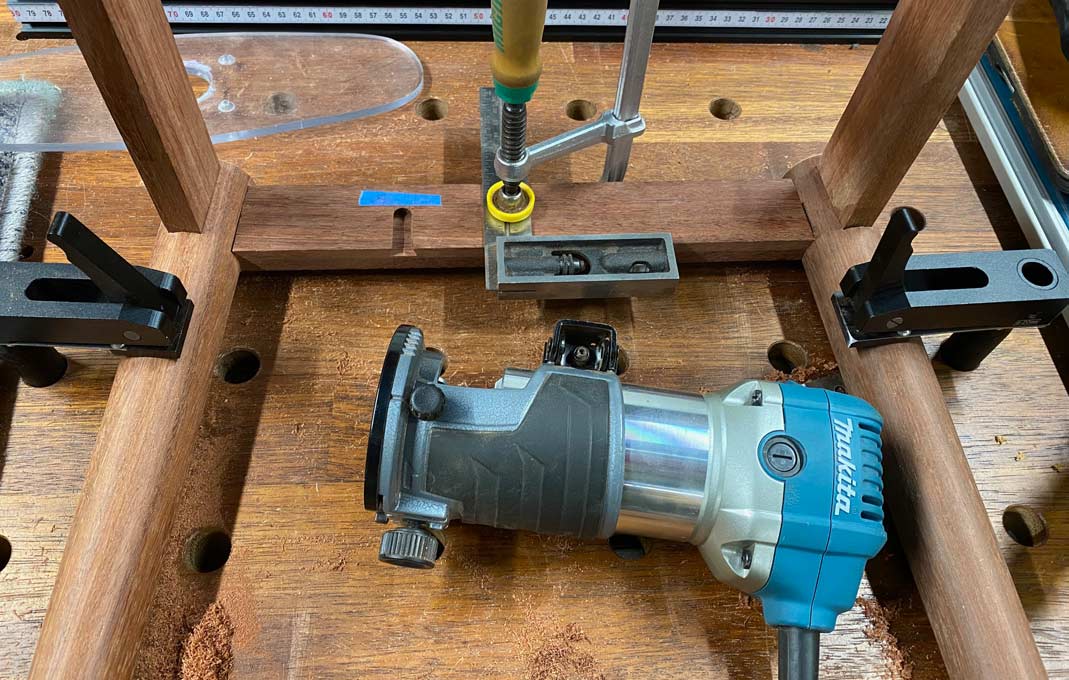

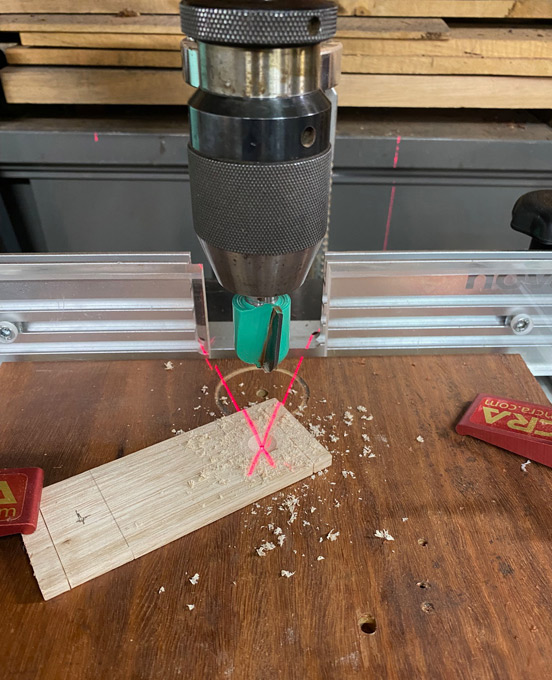

I needed to cut quarter-circles at the end of the support for the cabinet. One could do this with a bandsaw/jigsaw and spindle sander. I do not own a spindle sander .... but, wait, the drill press can become a spindle sander!

Here is the Voyager ...

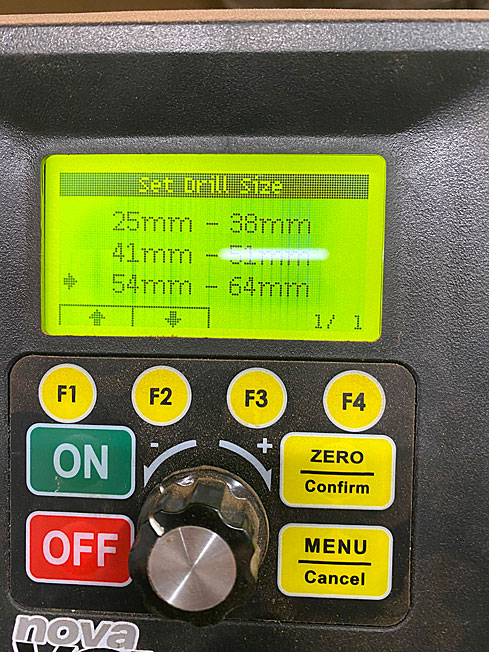

Select the drill bit. In this case, a hole saw ...

Set the size - 54mm ...

Choose hardwood ...

Confirm the speed, and it is ready to go ...

The workpiece is on the left, with a stop block on the right ...

Flip the workpiece for the second cut ...

And so on until all four supports are completed.

Easy peasy.

Regards from Perth

Derek

The drill press, that is.

This is one of those machines I do not want to be without. It has many uses, and today it was used to shape the ends of the risers for the floating cabinets. Not much in the way of hand skills here today.

I purchased the Nova Voyager about 5 years ago courtesy of a Black Friday special and a kind-hearted wife. This replaced a close-to-entry-level 12-speed Taiwanese press I had for about 25 years. For those unfamiliar with the Voyager, here is one feature that I find so amazing about this machine.

In all the time I have used this drill press I have yet to burn a blade or wood. A few buttons to push, and you can set any type of drill bit, of any size, to turn at the ideal speed for different densities of wood (or metal).

I needed to cut quarter-circles at the end of the support for the cabinet. One could do this with a bandsaw/jigsaw and spindle sander. I do not own a spindle sander .... but, wait, the drill press can become a spindle sander!

Here is the Voyager ...

Select the drill bit. In this case, a hole saw ...

Set the size - 54mm ...

Choose hardwood ...

Confirm the speed, and it is ready to go ...

The workpiece is on the left, with a stop block on the right ...

Flip the workpiece for the second cut ...

And so on until all four supports are completed.

Easy peasy.

Regards from Perth

Derek

Derek Cohen (Perth Oz)

Established Member

A Better Skyhook

The aim is to float the drawer cases above the bases.

There are two stretchers running across the top, and these join the sides with sliding dovetails ...

The sides, and hence the sockets, are angled at approximately 3 degrees, and the mating dovetails need to be angled to match ...

The ends are sawn away ...

... dovetailed ...

... and fitted ...

These stretchers are made lower than the aprons to hide them from sight.

The stretchers require a raised section, and these are finished with curved ends made by a hole saw bit on the drill press ..

... and sanded ...

The completed rests for the drawer cases ...

Later, all will be glued and screwed together.

Checking the effect ...

Regards from Perth

Derek

The aim is to float the drawer cases above the bases.

There are two stretchers running across the top, and these join the sides with sliding dovetails ...

The sides, and hence the sockets, are angled at approximately 3 degrees, and the mating dovetails need to be angled to match ...

The ends are sawn away ...

... dovetailed ...

... and fitted ...

These stretchers are made lower than the aprons to hide them from sight.

The stretchers require a raised section, and these are finished with curved ends made by a hole saw bit on the drill press ..

... and sanded ...

The completed rests for the drawer cases ...

Later, all will be glued and screwed together.

Checking the effect ...

Regards from Perth

Derek

Derek Cohen (Perth Oz)

Established Member

Fiddling all the way to the end

Time to put this build to bed ... or at least next to a bed.

The Jarrah bases are complete with two coats of hard wax oil ...

The plan is to bolt each drawer case to its base. The reason for this is it will make it possible to transport the nightstands more easily should this be in the future (there is a possibility I may enter them in the furniture competition put on by my club, which takes place in about 6 weeks - I doubt that anyone would take nightstands seriously). Transferring the holes to the case ...

Inserts are sunk into the case for the M6 bolts ...

... and bolted down ...

Time to make drawer pulls. My wife suggested going without anything to retain the clean lines. That would have been nice, just not possible. So the next best idea was to try and make the pulls blend in and be as unobtrusive as possible.

The Tasmanian Oak drawers receive a similar pull. Here the plan is drawn out ...

The underside of the pull receives a "dimple" for grip ...

Before cutting out the shape of the bandsaw and shaping with rasps and files, the tenons are pared away ...

Here the tiny drawer is being morticed for its tiny pull ...

This is repeated with the larger drawer ...

Before the pulls can be fitted, they each need to coped to match the curve of the drawer. But finally ...

Note that the pulls are the same diameter as the top of the legs.

The pull on the tiny drawer is a tinier version ...

Inside the drawer, I finalised the mechanism. This doubles as a guide and a drawer stop.

Closed ...

Open ...

The back can now be closed up. Each has a book-matched panel (mainly because I had run out of wood scraps), and is screwed down at the ends. Movement across the grain is permitted by the outer screw holes being elongated.

And, last but not least, two completed nightstands ...

I hope that you have enjoyed the journey with me.

Regards from Perth

Derek

Time to put this build to bed ... or at least next to a bed.

The Jarrah bases are complete with two coats of hard wax oil ...

The plan is to bolt each drawer case to its base. The reason for this is it will make it possible to transport the nightstands more easily should this be in the future (there is a possibility I may enter them in the furniture competition put on by my club, which takes place in about 6 weeks - I doubt that anyone would take nightstands seriously). Transferring the holes to the case ...

Inserts are sunk into the case for the M6 bolts ...

... and bolted down ...

Time to make drawer pulls. My wife suggested going without anything to retain the clean lines. That would have been nice, just not possible. So the next best idea was to try and make the pulls blend in and be as unobtrusive as possible.

The Tasmanian Oak drawers receive a similar pull. Here the plan is drawn out ...

The underside of the pull receives a "dimple" for grip ...

Before cutting out the shape of the bandsaw and shaping with rasps and files, the tenons are pared away ...

Here the tiny drawer is being morticed for its tiny pull ...

This is repeated with the larger drawer ...

Before the pulls can be fitted, they each need to coped to match the curve of the drawer. But finally ...

Note that the pulls are the same diameter as the top of the legs.

The pull on the tiny drawer is a tinier version ...

Inside the drawer, I finalised the mechanism. This doubles as a guide and a drawer stop.

Closed ...

Open ...

The back can now be closed up. Each has a book-matched panel (mainly because I had run out of wood scraps), and is screwed down at the ends. Movement across the grain is permitted by the outer screw holes being elongated.

And, last but not least, two completed nightstands ...

I hope that you have enjoyed the journey with me.

Regards from Perth

Derek

mikeduvar

Member

Enjoyed the journey a lot and learned a great deal. Thank you,

regards from the South of France

regards from the South of France

Very nice work. I have made a few ' nightstands ' as the Yanks call them. Personally I wouldn't trust the unsupported mitres but I have a little known tool called the ' Rockler Miter fold dado blade ' which machines a locking joint on mitres like this. You need a saw with a long 5/8 " arbour to use it. Very envious of the woods you can get in Australia and I might have made the handle out of Jarrah for a bit of contrast . Well done.

Derek Cohen (Perth Oz)

Established Member

Thanks.

I originally was going to make Jarrah handles, but my wife won the arm wrestling contest.

Regards from Perth

Derek

I originally was going to make Jarrah handles, but my wife won the arm wrestling contest.

Regards from Perth

Derek

Similar threads

- Replies

- 6

- Views

- 675

- Replies

- 2

- Views

- 324