I put the Sabre 350 fence on my BS350S this afternoon, and I'm not sure I'm happy with it, but I'm still working with it. The fence rail uses the same pair of holes the original fence rail used, and it is steady. This means I don't have to remove anything in order to change a blade, as I have to do with the Axminster fence. However, removing and installing the Axminster fence rail was easy and indexing marks I added made alignment easy.

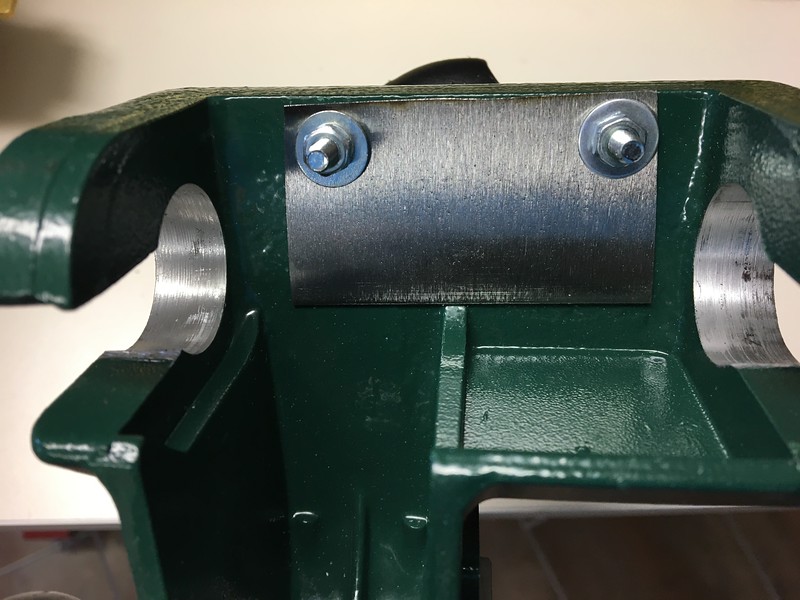

The very light (flimsy?) fence knuckle is another matter. The cam-action fence adjustment knob is much larger and longer than it needs to be, while the fence locking knob is much smaller and shorter than it needs to be and is difficult to tighten. The mechanism is not solid, and the fence extrusion moves while being locked in place after setting the angle. After a few attempts, I learned to under adjust the angle with the cam, and watch the fence settle into alignment as it was tightened.

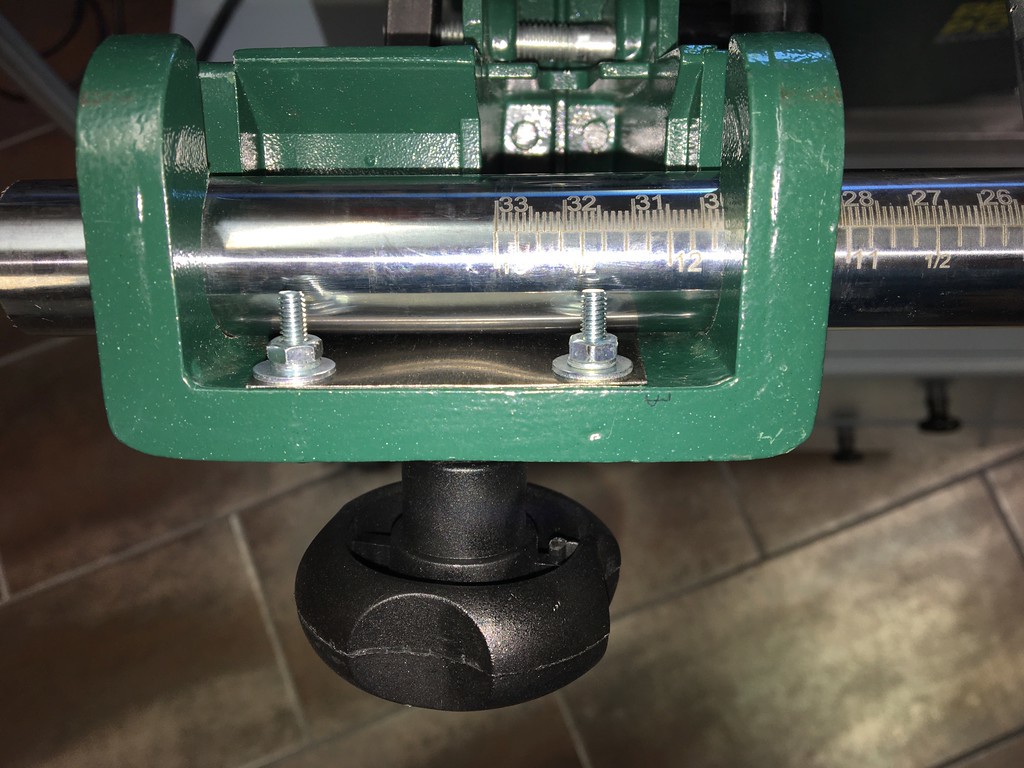

The metric and imperial scale is engraved (stamped?) into the guide rail, with two "zero" marks for the left and right side of the blade. However, the left side zero mark was off by almost two millimeters with respect to the edge of the blade. I managed to force the rail to the right in the two mounting holes to close the error by one millimeter. The only other option I have to reduce the error is to loosen the table to trunnion bolts and try to shift the table a bit...and then go through the table alignment process again.

Overall, at the end of day one, I'm not impressed with my €145 purchase. This could change after day two, but if I had been able to see the fence on a Sabre 350, I would not have purchased it and would have learned to love the Axminster fence. As an alternative that I was considering before I learned about the Sabre 350 fence, I will make a fence using 18mm MDF and some of the Magswitch Mag-Jigs I have.

The very light (flimsy?) fence knuckle is another matter. The cam-action fence adjustment knob is much larger and longer than it needs to be, while the fence locking knob is much smaller and shorter than it needs to be and is difficult to tighten. The mechanism is not solid, and the fence extrusion moves while being locked in place after setting the angle. After a few attempts, I learned to under adjust the angle with the cam, and watch the fence settle into alignment as it was tightened.

The metric and imperial scale is engraved (stamped?) into the guide rail, with two "zero" marks for the left and right side of the blade. However, the left side zero mark was off by almost two millimeters with respect to the edge of the blade. I managed to force the rail to the right in the two mounting holes to close the error by one millimeter. The only other option I have to reduce the error is to loosen the table to trunnion bolts and try to shift the table a bit...and then go through the table alignment process again.

Overall, at the end of day one, I'm not impressed with my €145 purchase. This could change after day two, but if I had been able to see the fence on a Sabre 350, I would not have purchased it and would have learned to love the Axminster fence. As an alternative that I was considering before I learned about the Sabre 350 fence, I will make a fence using 18mm MDF and some of the Magswitch Mag-Jigs I have.