Sportique

Established Member

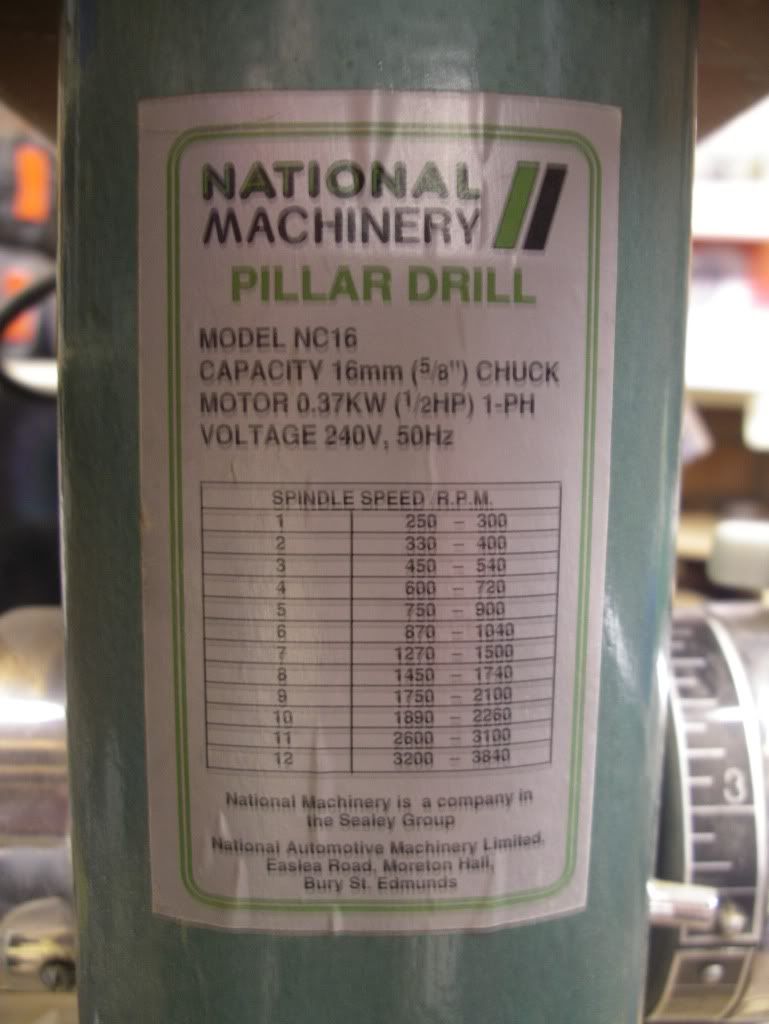

H E L P - does anyone own a similar pillar drill please? I need help with selecting various speeds.

The machine is probably about 30-40 years old and I have been unable to contact the manufacturer.

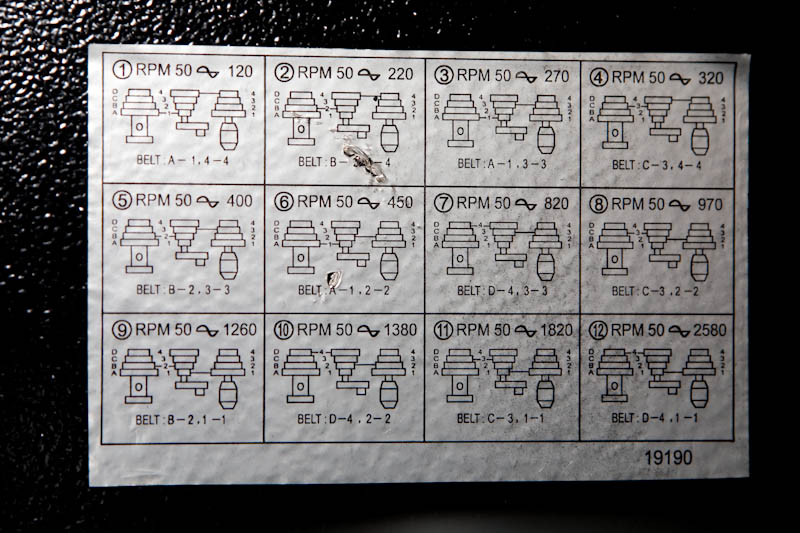

I have been able to set the lowest and highest speeds - this seems fairly clear, however, I do not know how to set the drive belts on the three pulleys for the speeds marked on the machine plate. Maybe someone with a machine manual could contact me.

how to set the drive belts on the three pulleys for the speeds marked on the machine plate. Maybe someone with a machine manual could contact me.

Thanks

Dave

The machine is probably about 30-40 years old and I have been unable to contact the manufacturer.

I have been able to set the lowest and highest speeds - this seems fairly clear, however, I do not know

Thanks

Dave