adzeman

Established Member

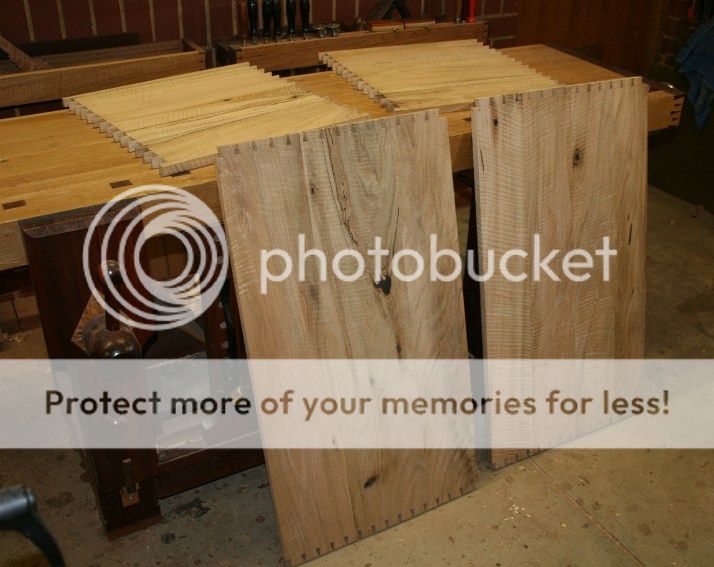

Missed posting a picture

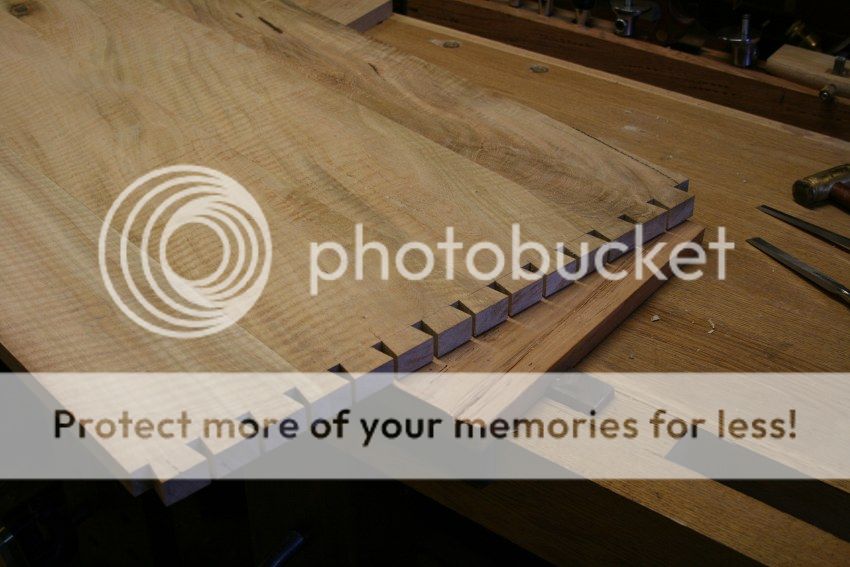

Two sharp taps just slightly off the base line and then chop further back a couple of times taking out the waste with a coping saw.

Two sharp taps just slightly off the base line and then chop further back a couple of times taking out the waste with a coping saw.